What is a PWB?

A PWB, or printed wiring board, refers to the base board used to physically support and connect electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate. The term PWB emerged in the early days of electronic circuit manufacturing. Key characteristics of PWBs include:

- Copper tracks or traces laminated onto a non-conductive substrate like FR-4

- Through-hole component mounting using leads soldered into plated holes

- Larger component sizes and lead pitches compared to modern PCBs

- Used mainly for lower-density, simpler circuit designs

What is a PCB?

A PCB, or printed circuit board, is the modern evolution of printed wiring boards. PCBs serve the same fundamental purpose of connecting electronic components, but use more advanced manufacturing processes and materials to enable higher component density, reliability, and performance. Key characteristics of PCBs include:

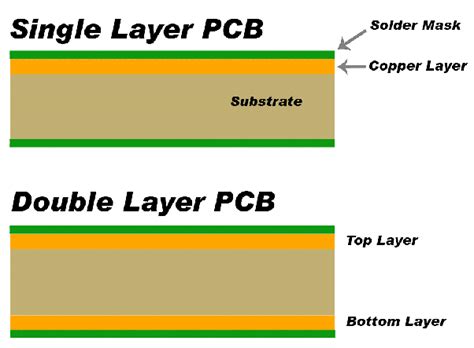

- Multi-layer designs with conductive copper layers separated by insulating layers

- High-density surface mount components with small footprints and lead pitches

- Plated through-holes called vias to connect different layers

- Solder Mask and silkscreen layers for insulation and labeling

- Wider range of substrate materials (FR-4, ceramic, flex, etc.) for different applications

- Integral to virtually all modern electronic devices

PWB vs PCB: What’s the Difference?

While PWBs and PCBs serve the same basic function, there are some notable differences between the two terms:

| Factor | PWB | PCB |

|---|---|---|

| Terminology | Older term from early electronics manufacturing | Modern, widely accepted term |

| Manufacturing | Copper tracks laminated onto non-conductive substrate | Multi-layer designs with advanced materials |

| Mounting | Mainly through-hole components | Surface mount and high-density designs |

| Density | Lower component density | Higher component density |

| Applications | Simpler, lower-performance electronics | Virtually all modern electronic devices |

Essentially, a PCB can be considered a more advanced and capable type of PWB. All PCBs are technically also PWBs, but not all PWBs would be considered PCBs by modern standards.

Why the Shift from PWB to PCB Terminology?

The transition from referring to circuit boards as PWBs to calling them PCBs occurred gradually as electronics manufacturing technologies advanced. Several key developments drove this shift:

-

Surface mount technology (SMT): The introduction of SMT allowed for much smaller components and higher circuit density than through-hole designs. SMT became the default standard for PCB Assembly.

-

Multi-layer boards: Newer PCB designs incorporated multiple copper layers separated by insulating layers, enabling more complex circuits and higher density than single-sided PWBs.

-

Advanced materials: The introduction of new substrate materials beyond basic FR-4, such as high-frequency laminates, ceramic, and flexible substrates, expanded the applications and capabilities of modern PCBs.

-

Computer-aided design (CAD) tools: Powerful CAD software for schematic capture and PCB Layout made it easier to design and manufacture complex, high-density PCBs.

-

Industry standardization: As PCB Technology became ubiquitous, industry standards and terminology coalesced around the term “PCB” rather than “PWB”.

Together, these advancements made “PCB” the standard term for modern circuit boards, while “PWB” became less common and more associated with older or simpler circuit designs.

Is PWB Still Used Today?

While PCB is by far the most common and accepted term nowadays, PWB is still used in some contexts:

-

Legacy designs: Older electronic products or designs created before the widespread adoption of PCB terminology may still refer to the boards as PWBs.

-

Specific industries: Some industries, such as aerospace and defense, may still use the term PWB in certain standards or documentation.

-

Educational or introductory contexts: PWB may be used as a more generic, beginner-friendly term when teaching electronics manufacturing or explaining circuit boards to non-technical audiences.

However, in the vast majority of industry contexts, PCB is the standard and preferred term. Using PWB nowadays may cause confusion or make designs seem outdated.

Frequently Asked Questions

1. Are PWBs and PCBs the same thing?

Technically, a PCB is a type of PWB, but not all PWBs are PCBs. PCBs are the modern standard with advanced features like multi-layer construction and high density surface mount components, while PWB typically refers to simpler, older designs.

2. Can I use the terms PWB and PCB interchangeably?

While PWBs and PCBs serve the same basic purpose, using the terms interchangeably is not recommended as it may cause confusion. PCB is the modern industry standard term, while PWB is associated more with legacy designs or specific niche uses.

3. What are the benefits of using the term PCB instead of PWB?

Using PCB instead of PWB ensures clarity and aligns with industry standards. It avoids potential confusion and correctly conveys the modern, advanced nature of Circuit Board Designs.

4. Are there any cases where I should use the term PWB?

PWB may still be appropriate when referring to legacy designs, working with certain industry standards that still use the term, or explaining circuit boards in a very general, introductory context. However, PCB is preferred in most modern industry contexts.

5. Will using the term PWB cause issues for my circuit board design?

Using PWB instead of PCB will not directly impact the functionality of a circuit board design. However, it may cause confusion in communications, documentation, or manufacturing processes because PCB is the expected modern standard term.

In summary, while PWBs and PCBs refer to the same basic concept of printed circuit boards, PCB has become the standard term that represents the advanced capabilities of modern electronics manufacturing. Using the term PCB ensures clarity, avoids outdated connotations, and aligns with industry expectations. Adopting PCB as the default term is recommended for most circuit board design and manufacturing applications today.

Leave a Reply