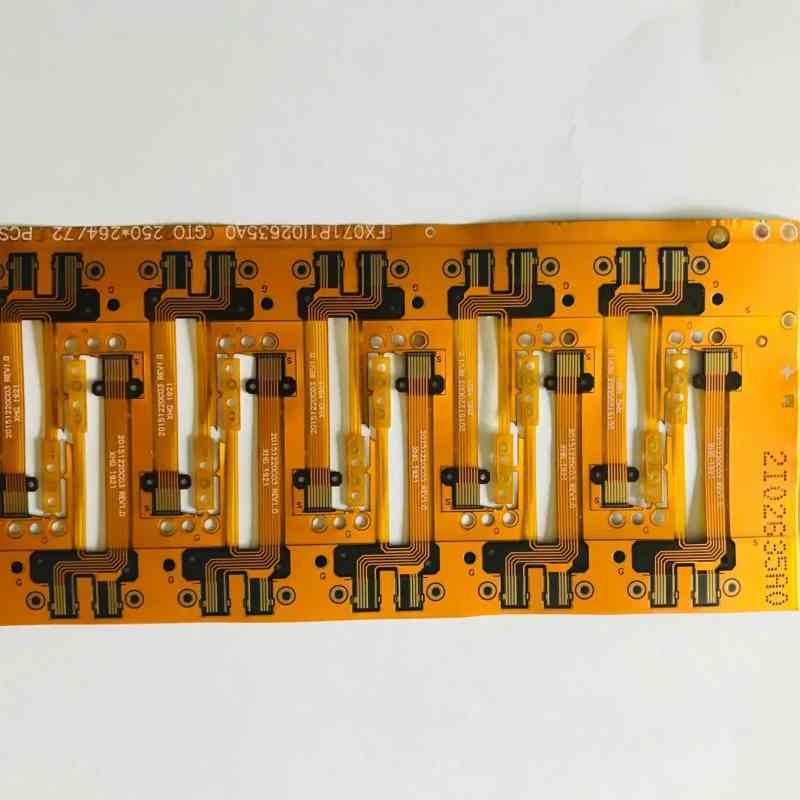

Flexible PCB Manufacturer

Prototype rigid-flex and flex PCB fabrication & manufacturing, from single layer to 12 layer Flex PCB

99.8%

Client retention

100% satisfy clients in our work

18+

Years of experience

Fully focused on flex PCB manufacturing

1000+

Clients

Solid and responsible technical team

10K+

Project value

99.8% successfully all project done

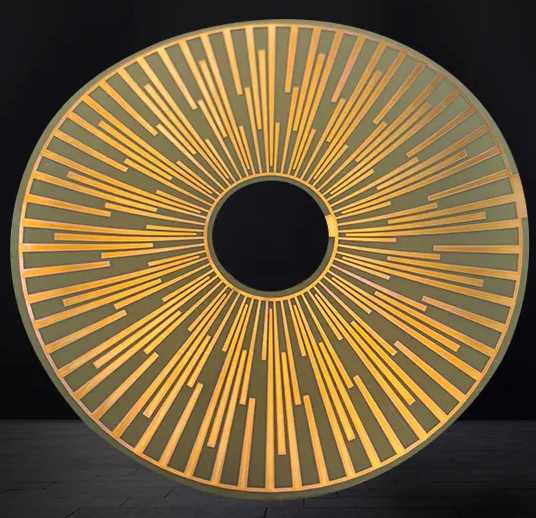

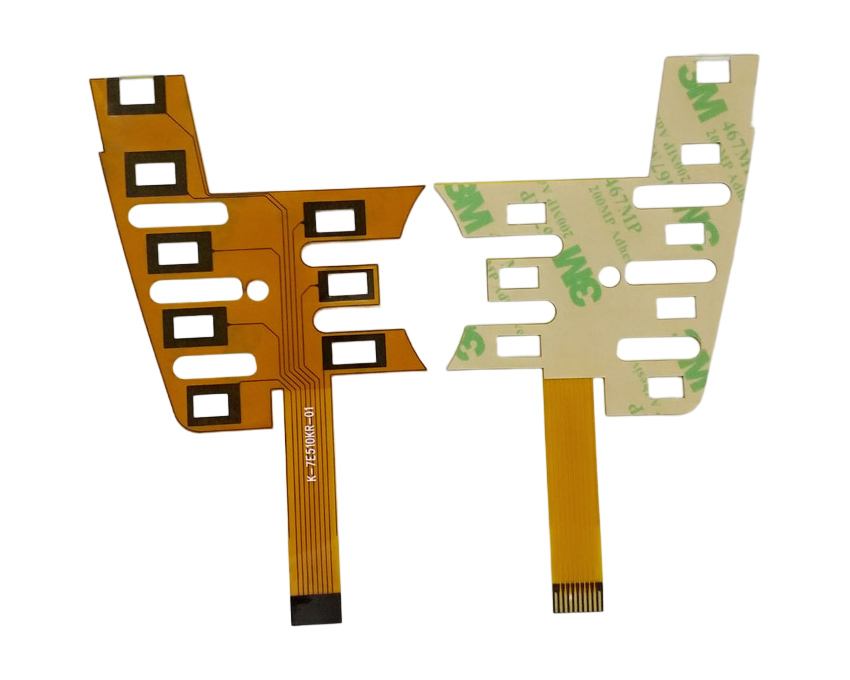

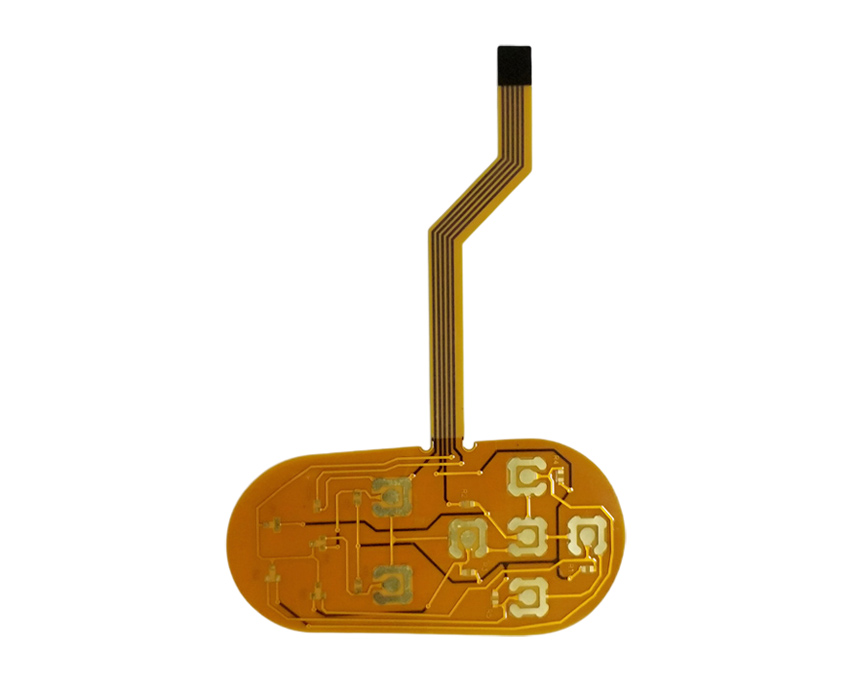

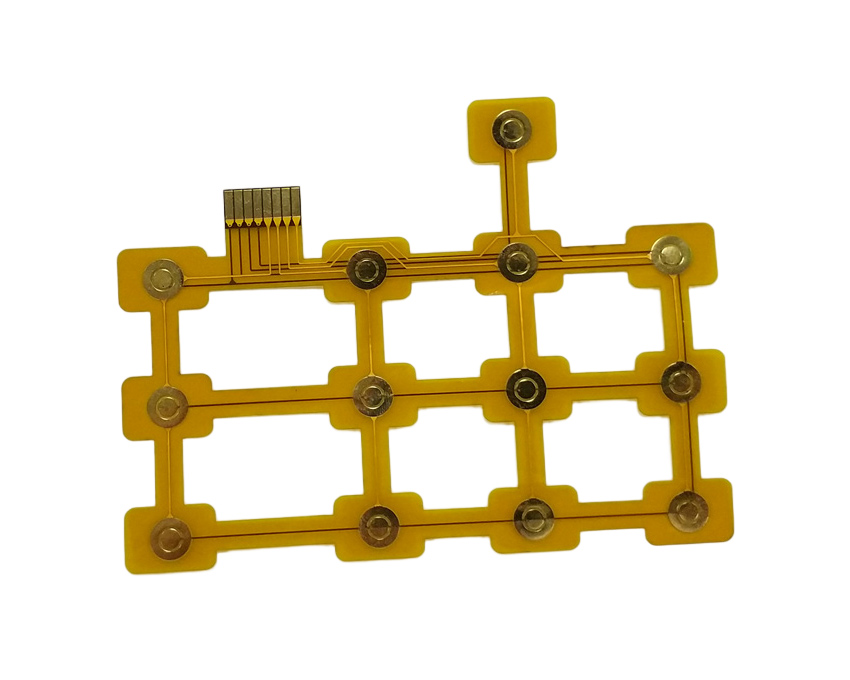

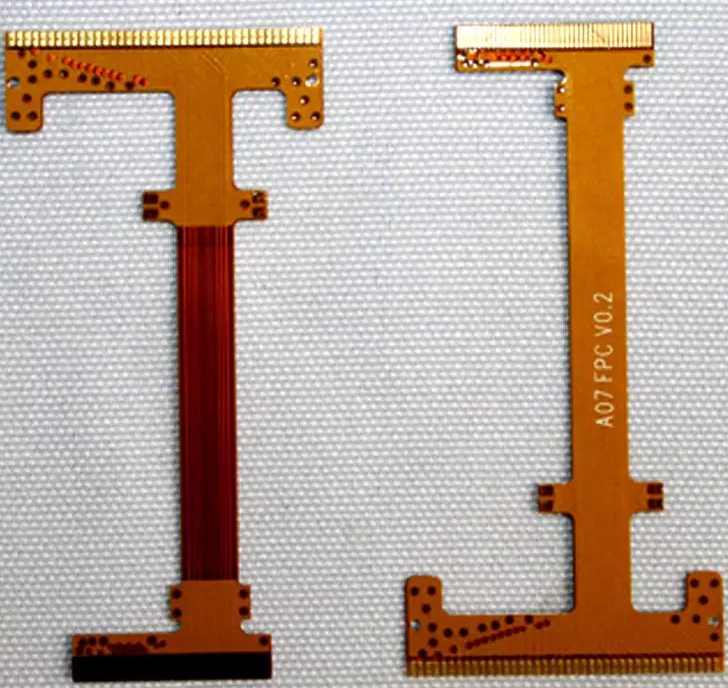

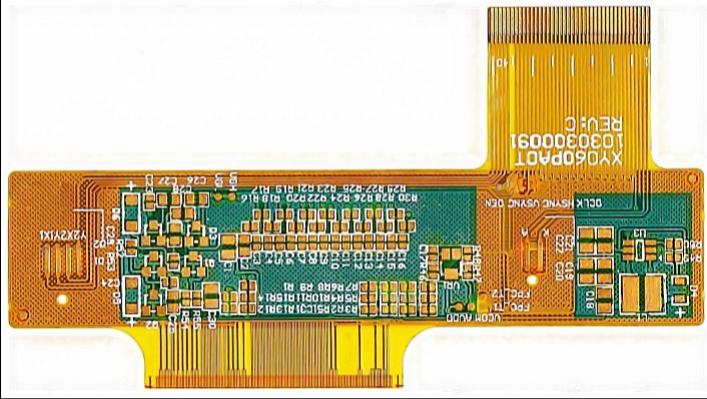

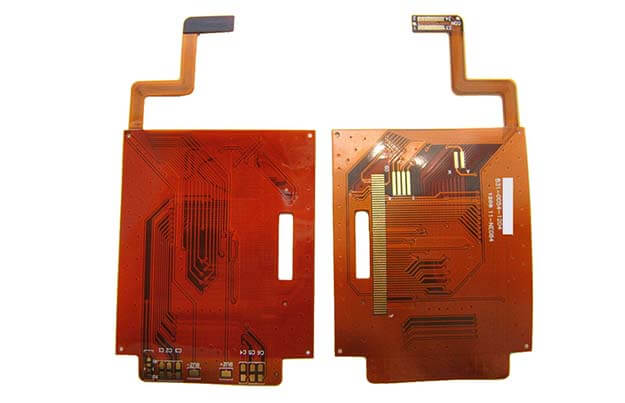

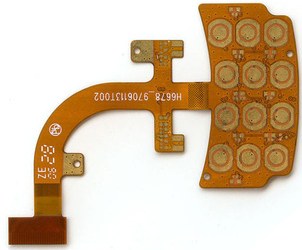

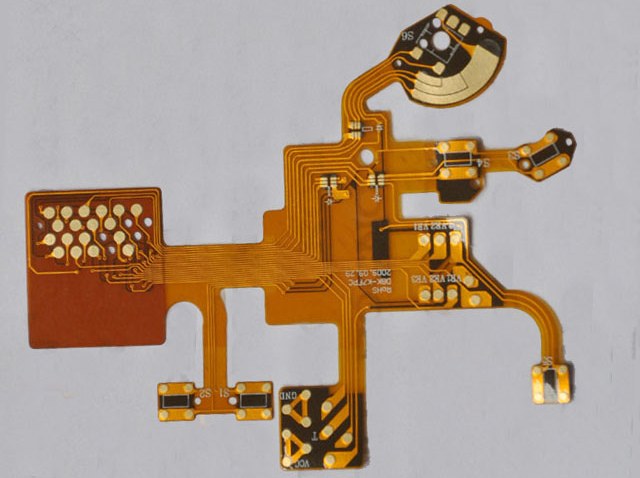

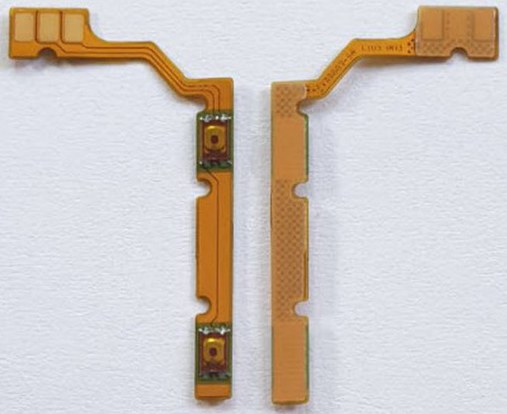

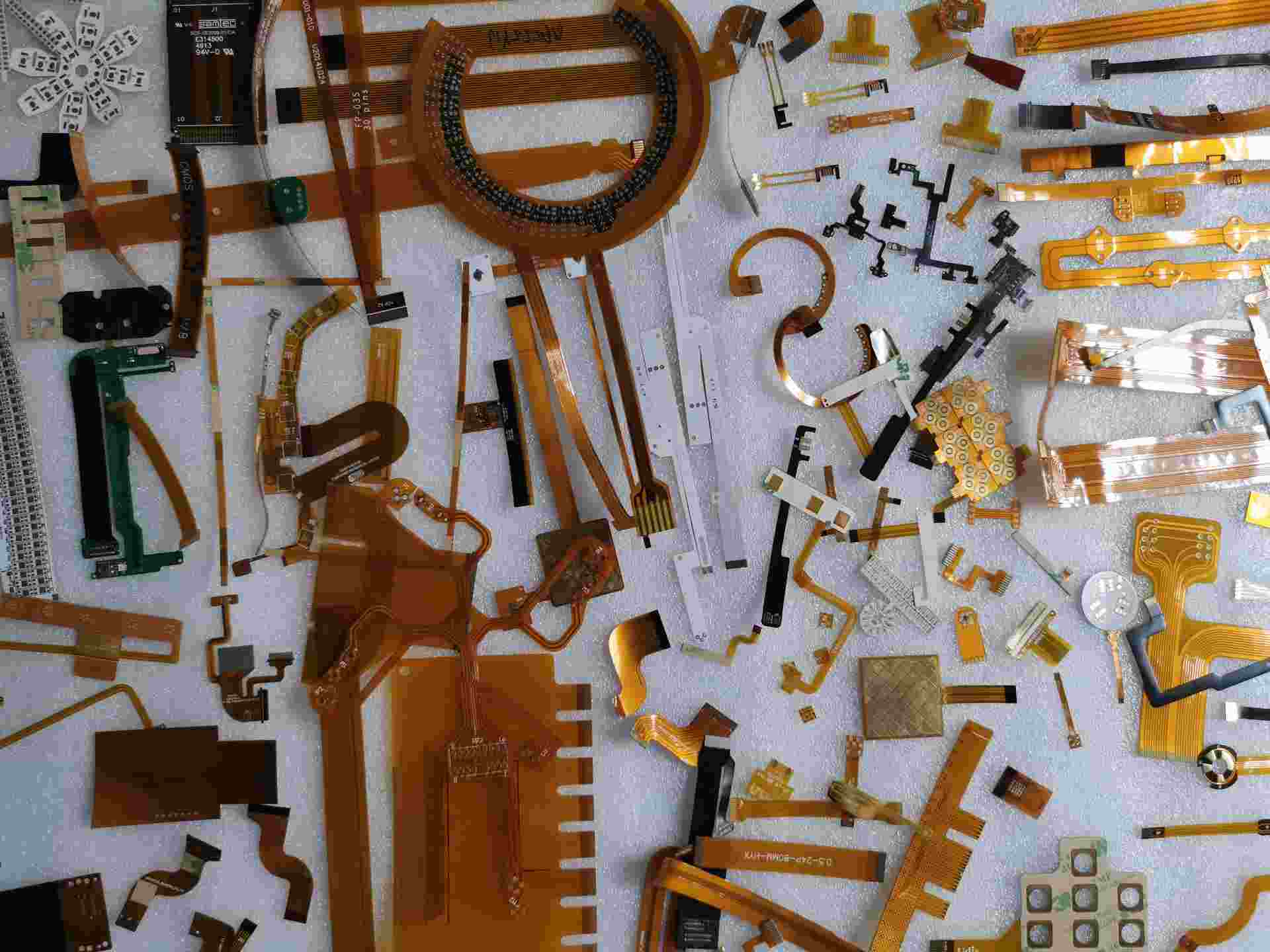

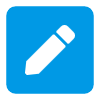

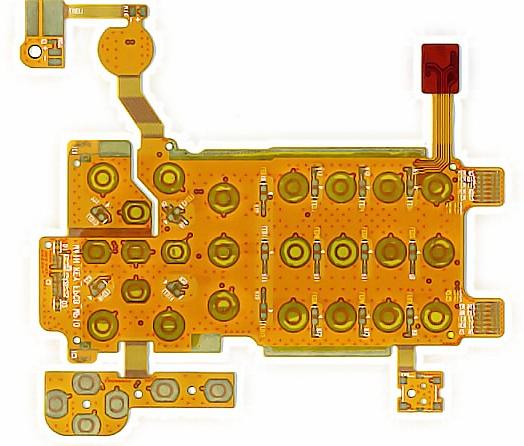

Flex PCB Products

This is your awesome sub title

Flex PCB Solution

This is your awesome sub title

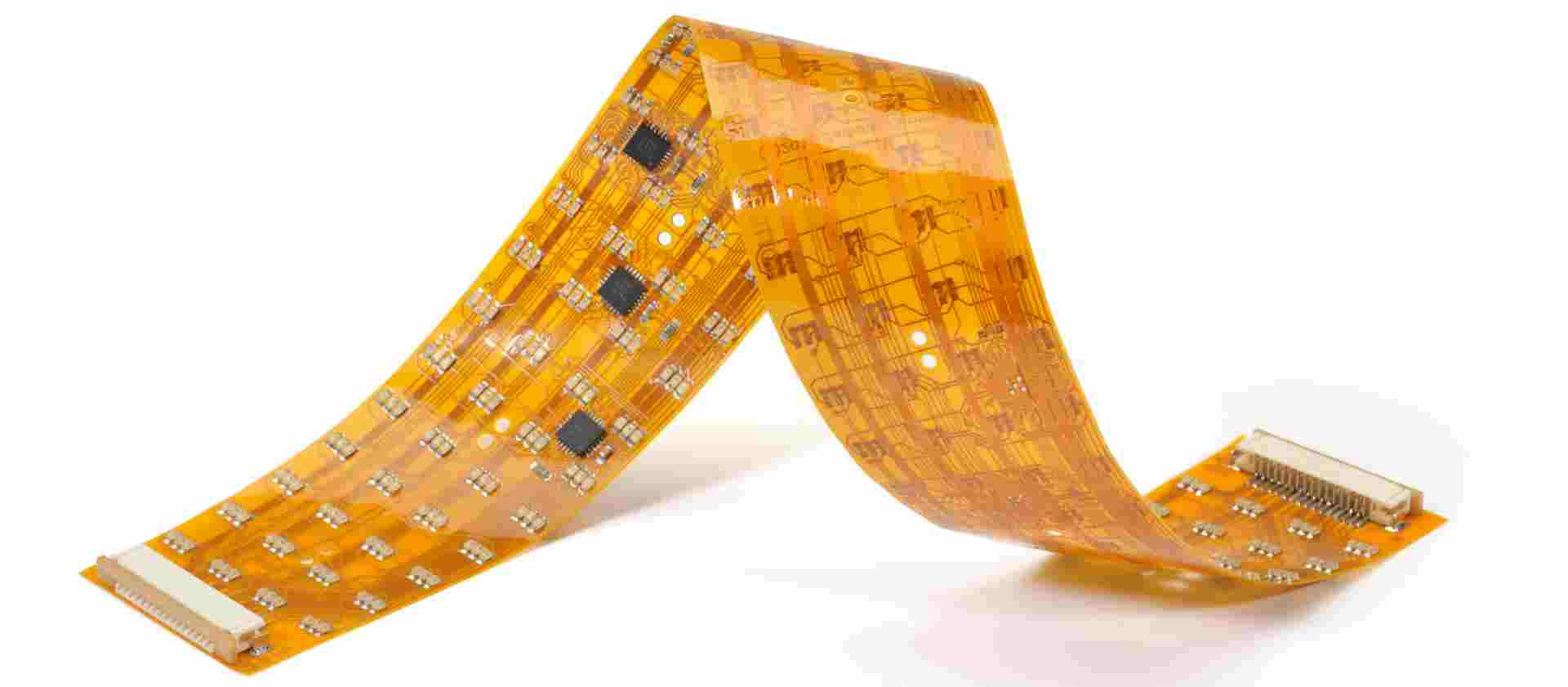

Flexible Printed Circuits Solutions

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Heater Solutions

Lorem ipsum dolor sit amet, consectetur adipiscing elit

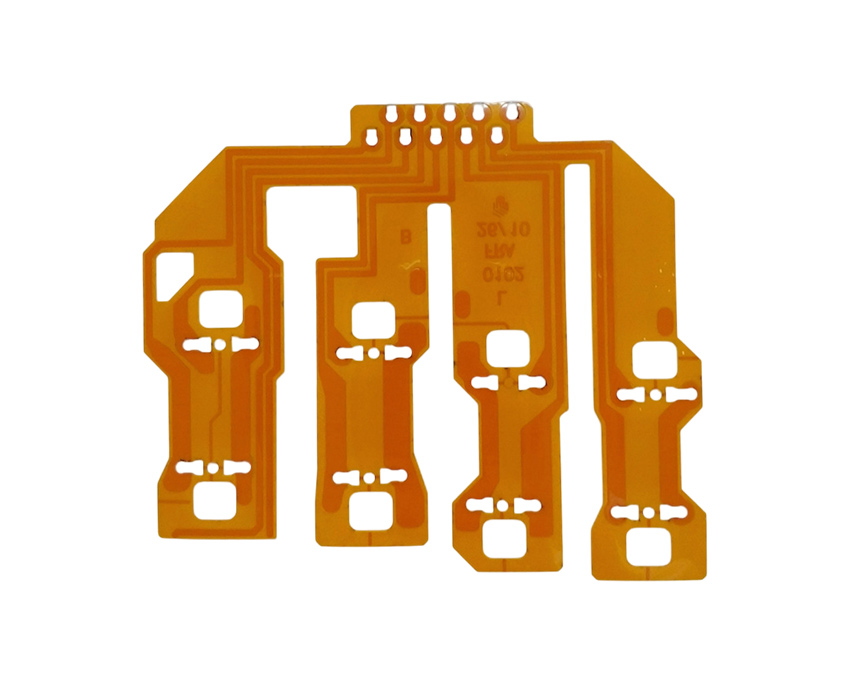

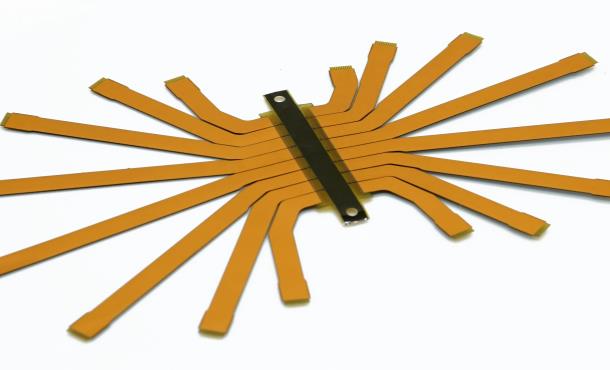

Wires Replace Solutions

Lorem ipsum dolor sit amet, consectetur adipiscing elit

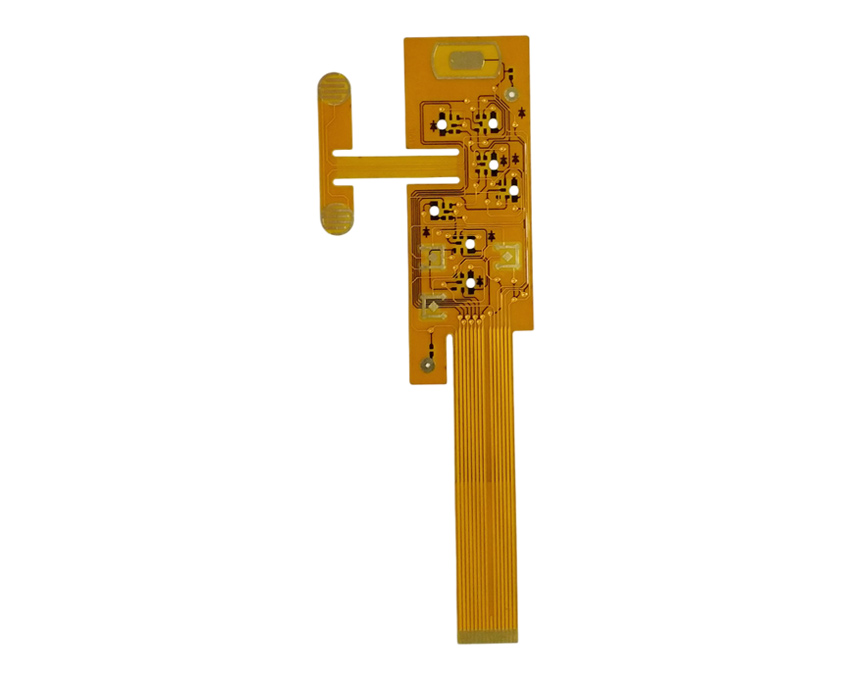

Multilayer Flex Circuits

Lorem ipsum dolor sit amet, consectetur adipiscing elit

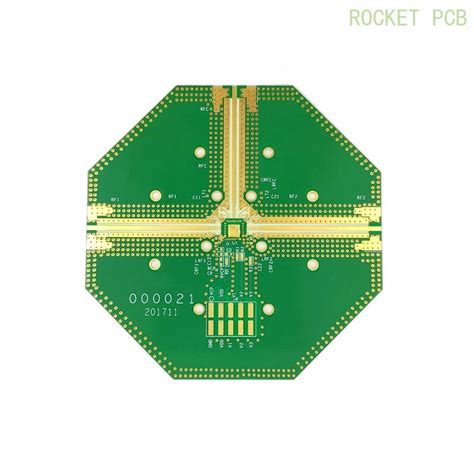

Rigid Flex Solutions

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Flex PCB Assembly Solution

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Electronic Industry Served

Medical Device, Military Electronics, Industrial control system, Wearable device

Medical

Diagnostic hardware, medical electronics and medical imaging devices.

Wearable Device

wearable applications continue to grow at a rapid pace and products are being introduced across most every market

Military/Defense

Military electronic devices have unique reliability, dependability, and survivability requirements in addition to strict performance standards. Rigid flex and flex circuits enable defense contractors to meet these demands

Automotive

Camera modules, lighting and other automotive electronics (LIDAR).

Industrial & Commercial

Robotics, consumer electronics and LED lighting applications.

Aerospace/Aeronautical

Aero electronics systems are exposed to higher levels of shock and vibration while simultaneously evolving toward weight reduction, increased component density and improved functionality

Who We Are

We’re Flex PCB Manufacturer.

FlexPCB focuses on responsive actions that ensure continuous quality improvements while providing attentive customer support. Our systems are designed to meet delivery and quality commitments and achieve the highest level of customer satisfaction.

We can turn your flexible PCB manufacturing order in as quick as 24 hours.

- Flex PCB up to 12 layers

- Drill to copper – Outer layers 8mil

- Drill to copper – Inner layers 10mil

- Copper Thickness 1/3oz – 4oz

- Minimum Hole Size 0.004″

- Minimum Trace/Space 0.003″/0.003″

- Minimum Pitch 0.5 mm

- stiffener: PI Fr4 Aluminum

What We Do

Flex your design potential

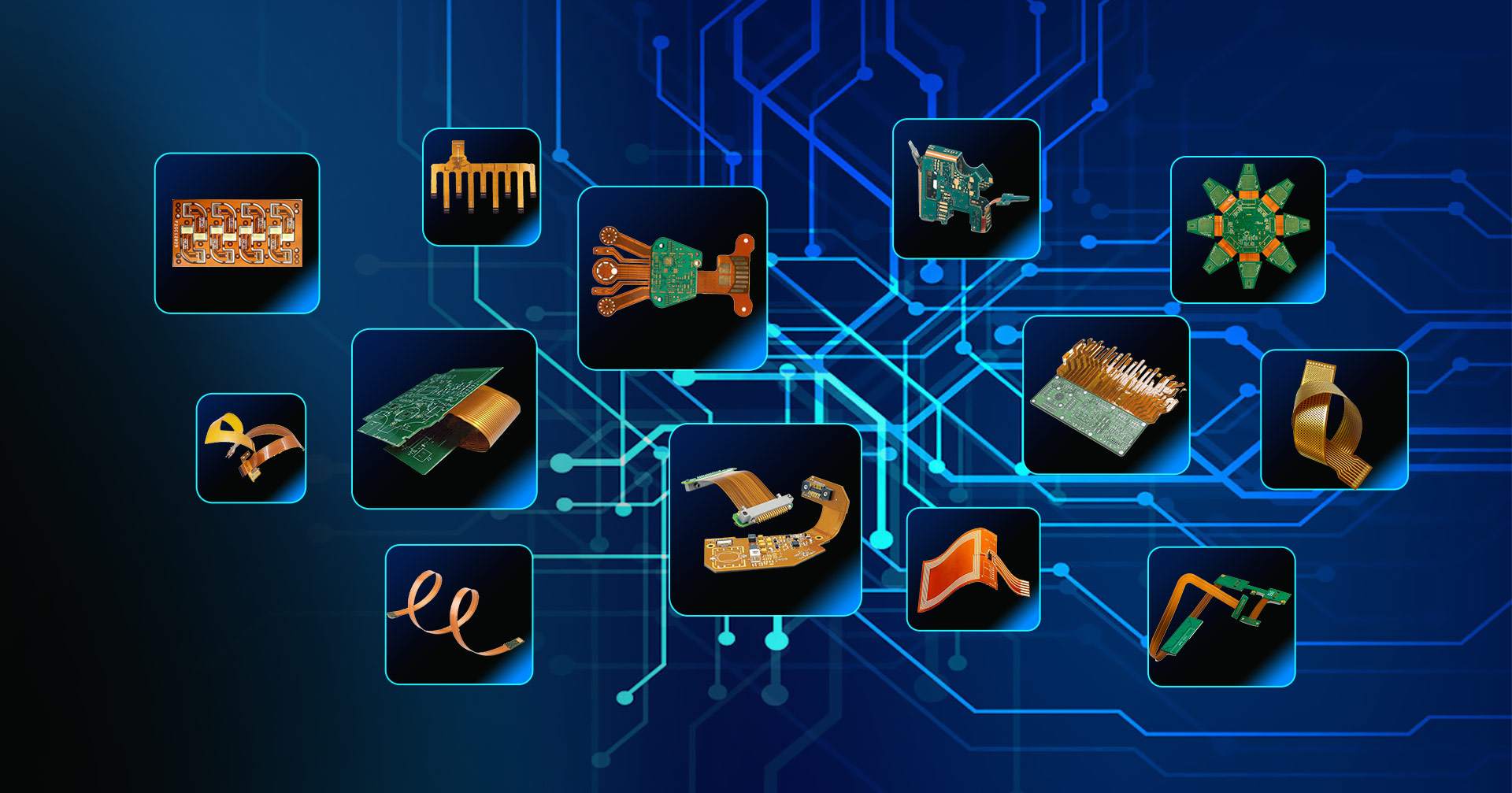

A Flex PCB or FPCB is a patterned arrangement of printed circuitry and components that utilizes flexible based material with or without flexible coverlay. These flexible electronic assemblies may be fabricated using the same components used for rigid printed circuit boards, but allowing the board to conform to a desired shape (flex) during its application.

- Polyimide (Kapton) 0.5 mil to 5 mils (.012mm – .127mm)

- Adhesiveless copper clad base material 1 mil to 5 mils

- Flame retardant laminate, base material, and Coverlay

- High performance epoxy laminate and prepreg

- UL and RoHS compliant material on request

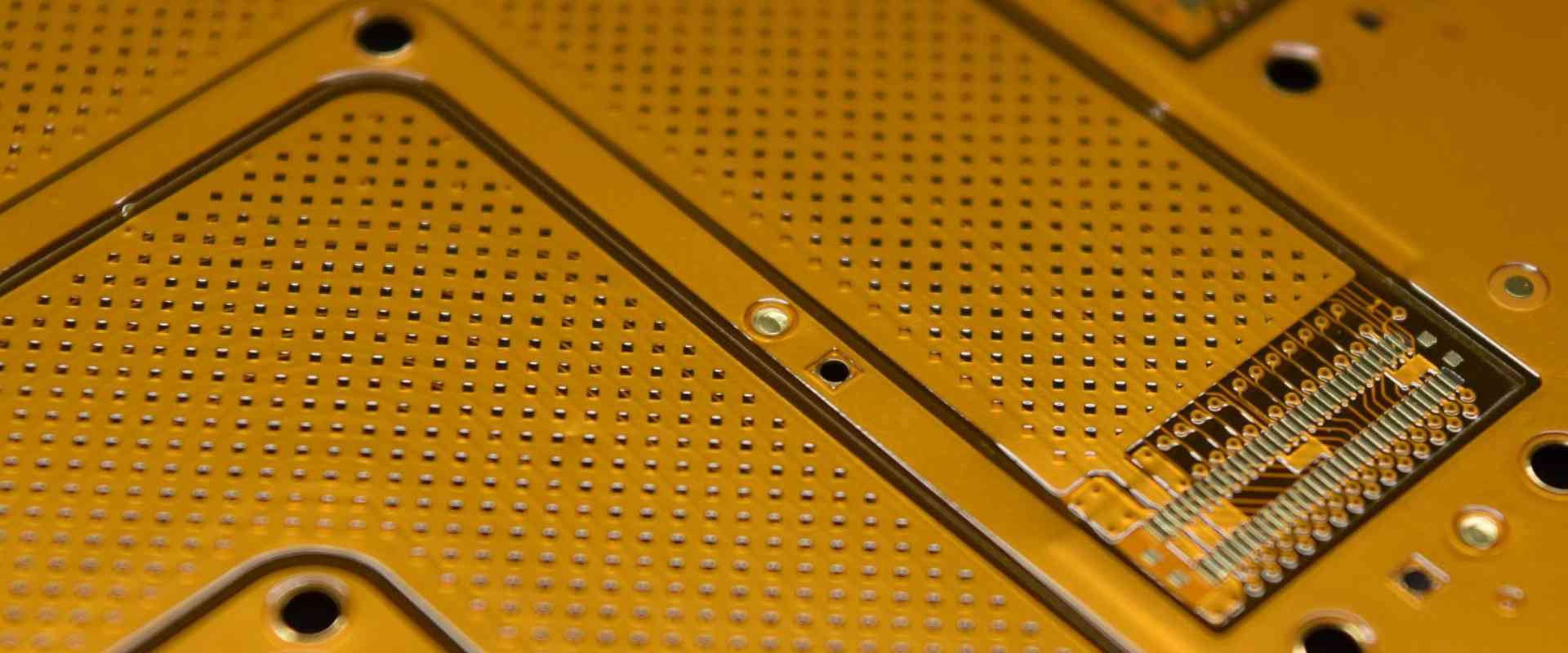

Highlighted manufacturing capabilities.

As a leading prototype-to-production flexible PCB manufacturer, we have flex and rigid-flex PCB capabilities that other companies can’t compete with. As your flexible circuit supplier, you will be able to manufacture boards smaller line trace spaces and micro-vias.

New Projects

This is your awesome sub title

From Our Blog Posts

This is your awesome sub title

-

Hybrid PCB Materials Types and Challenges

Introduction to Hybrid PCBs Hybrid PCBs, also known as hybrid printed circuit boards, are a combination of different types of materials and technologies used to create a single circuit board. These boards are designed to take advantage of the strengths of each material and technology while minimizing their weaknesses. Hybrid […]

-

Capability of the PCB Surface Mount Plant

Introduction to PCB Surface Mount Technology PCB Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry since its introduction in the 1960s. SMT allows for the placement of electronic components directly onto the surface of a printed circuit board (PCB), rather than through holes in the board. This technology […]

-

Discount PCB Fabrication – 20% Off for PCBs from RAY PCB

Introduction to PCB Fabrication and RAY PCB Printed Circuit Boards (PCBs) are the backbone of modern electronics. They provide a reliable and efficient way to connect electronic components and create complex circuits. PCB fabrication is the process of designing, manufacturing, and assembling these boards. RAY PCB is a leading provider […]

99.5%

Satisfaction

18+

Experiences

1,000+

Global Customers

6000+

Projects

FLEX PCB APPLICATIONS

This is your awesome description

Power Electronics

Another benefit of a flexible printed circuit board is that it can be coupled with highly flexible, thin layers of copper, which means the board can handle heavier power currents. This is especially important in devices that will require more power to operate at full capacity, like those found in the power electronics industry.

Consumer Electronics

Flexible PCBs are typically used in small electronic products like cell phones, tablets, cameras, video recorders and other similar smaller gadgets on the market today. These products may be transported or handled regularly, making the flexible PCB’s resistance to shock and vibration a useful feature.

Industrial

Industrial electronics often handle massive amounts of vibration and stress, so flexible PCBs with shock absorption and anti-vibration capabilities are a must.

Medical Systems

mall and dense electronic designs are becoming increasingly important in the medical industry, with handheld surgical technology and even electronic implants growing in popularity. Flexible PCBs can be applied in both cases, meeting the durability and size requirements of surgical technology and the necessary flexing ability for implants.

High-Speed Digital, RF Microwave Applications

The reliability of flexible PCBs makes them ideal for handling high-frequency signals.

Aerospace

Thanks to their remarkable ability to handle the stress of extreme temperatures and vibrations, flex PCBs are uniquely suited for aerospace applications such as satellites. They also can take on unusual shapes that are well suited for spacecraft and substituting connectors that are more prone to failure.

Automobiles

With the automotive industry increasingly turning toward electronic components, circuits that can handle the vibrations and stresses of a vehicle’s interior are more important than ever. A flexible printed circuit board offers a valuable option for the industry, providing a durable yet cost-effective option.

LED

LED lighting is massively popular today in both residential and commercial applications. This is primarily because of LED technology’s incredible power efficiency. Heat is often the only concern, which can be mitigated with a flexible printed circuit board and its effective heat transfer properties.

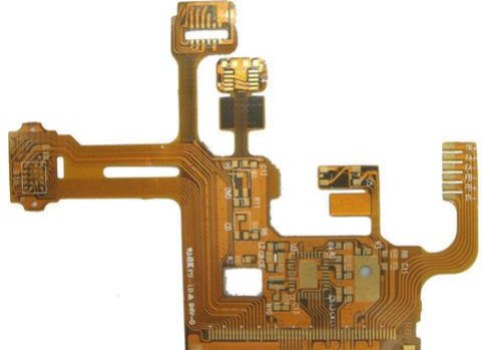

Smartphones

To seize market share and stimulate consumers’ purchase willingness, mobile phone brands continue to innovate and enrich product functions, resulting in a higher demand for PCBs especially, Flex PCB. At first, Flex PCB is used for LCD panels, LCD modules, camera modules, buttons, and batteries in mobile phones.

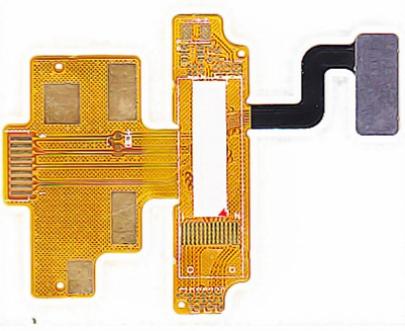

Cost Effective Flex & Rigid-Flex PCBs

Medical Flex

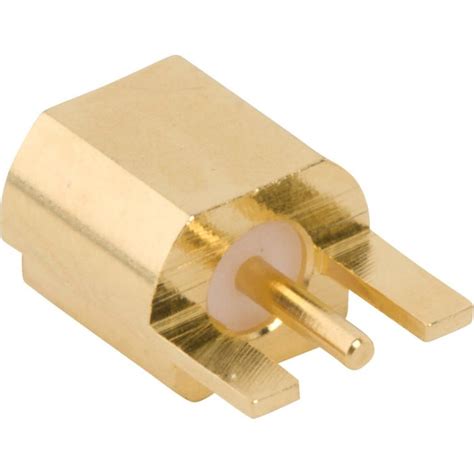

Connector Flex