Introduction to PCB-UK

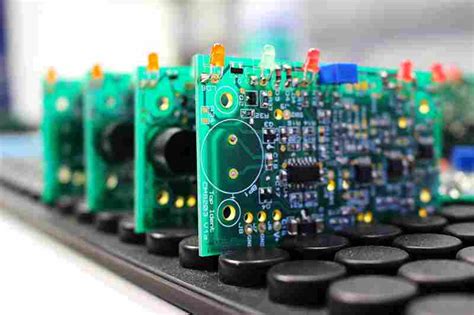

PCB-UK is a leading manufacturer of high-quality printed circuit boards (PCBs) based in the United Kingdom. With state-of-the-art facilities and a team of experienced professionals, PCB-UK offers a wide range of PCB solutions for various industries, including automotive, aerospace, medical, and consumer electronics.

What is a PCB?

A printed circuit board (PCB) is a fundamental component in modern electronics. It is a flat board made of insulating materials, such as fiberglass or composite epoxy, with conductive copper traces etched onto its surface. These traces connect various electronic components, such as resistors, capacitors, and integrated circuits, to form a complete electronic circuit.

PCBs come in different types, depending on the number of layers and the complexity of the circuit design:

| PCB Type | Description |

|---|---|

| Single-sided | Conductive traces on one side of the board |

| Double-sided | Conductive traces on both sides of the board |

| Multi-layer | Multiple layers of conductive traces separated by insulating layers |

| Flexible | Made of flexible materials for applications requiring bending or folding |

| Rigid-flex | Combination of rigid and flexible sections for complex designs |

PCB-UK’s Manufacturing Process

Design and Prototyping

The PCB manufacturing process at PCB-UK begins with the design and prototyping stage. Customers can submit their PCB designs in various file formats, such as Gerber, ODB++, or IPC-2581. PCB-UK’s experienced design team reviews the files for manufacturability and provides feedback or suggestions for improvement.

For customers who require assistance with PCB design, PCB-UK offers design services using industry-standard EDA (Electronic Design Automation) tools, such as Altium Designer, Cadence OrCAD, and Mentor Graphics PADS.

PCB Fabrication

Once the design is finalized, PCB-UK proceeds with the fabrication process. The key steps in PCB fabrication include:

-

Copper Clad Laminate Preparation: The process begins with the selection of the appropriate copper clad laminate (CCL) based on the PCB design requirements. The CCL is cut to size and cleaned to remove any contaminants.

-

Drilling: Holes are drilled into the CCL for through-hole components and vias using high-speed CNC drilling machines.

-

Patterning: The copper traces are patterned onto the CCL using a photolithography process. This involves applying a light-sensitive resist, exposing it to UV light through a photomask, and developing the resist to reveal the desired copper pattern.

-

Etching: The exposed copper is etched away using a chemical solution, leaving only the desired copper traces on the board.

-

Lamination (for multi-layer PCBs): For multi-layer PCBs, the individual layers are aligned and laminated together under high pressure and temperature to form a single board.

-

Surface Finish: A surface finish, such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative), is applied to protect the copper traces and improve solderability.

-

Solder Mask and Silkscreen: A solder mask is applied to the PCB to protect the copper traces from oxidation and prevent solder bridges during assembly. A silkscreen layer is added to provide component labels and other markings.

-

Electrical Testing: The fabricated PCBs undergo electrical testing to ensure they meet the design specifications and are free of short circuits or open connections.

PCB Assembly

PCB-UK offers both PCB fabrication and assembly services. The PCB assembly process involves the following steps:

-

Solder Paste Application: Solder paste is applied to the PCB pads using a stencil or screen printing process.

-

Component Placement: Surface mount (SMT) and through-hole (THT) components are placed onto the PCB using automated pick-and-place machines or manual assembly.

-

Reflow Soldering: The PCB with the placed components is passed through a reflow oven, where the solder paste melts and forms a permanent electrical and mechanical connection between the components and the PCB.

-

Wave Soldering (for THT components): If the PCB contains through-hole components, it undergoes a wave soldering process, where the board is passed over a molten solder wave to solder the component leads to the PCB.

-

Inspection and Testing: The assembled PCBs are visually inspected and undergo functional testing to ensure they meet the required specifications and performance criteria.

PCB-UK’s Quality Assurance and Certifications

PCB-UK is committed to maintaining the highest quality standards in PCB manufacturing. The company has implemented a robust quality management system (QMS) that adheres to international standards and best practices.

ISO 9001:2015 Certification

PCB-UK is ISO 9001:2015 certified, which demonstrates the company’s commitment to continuous improvement and customer satisfaction. The ISO 9001:2015 standard sets out the requirements for a quality management system that ensures consistent, high-quality products and services.

IPC Standards Compliance

PCB-UK follows the IPC (Association Connecting Electronics Industries) standards for PCB manufacturing and assembly. These standards ensure that the PCBs produced by PCB-UK meet the industry’s best practices for quality, reliability, and performance.

Some of the key IPC standards followed by PCB-UK include:

- IPC-A-600: Acceptability of Printed Boards

- IPC-6012: Qualification and Performance Specification for Rigid Printed Boards

- IPC-A-610: Acceptability of Electronic Assemblies

- IPC-J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies

In-House Testing and Inspection

PCB-UK has invested in advanced testing and inspection equipment to ensure the quality of its PCBs. Some of the in-house testing and inspection capabilities include:

- Automated Optical Inspection (AOI)

- X-ray Inspection

- Flying Probe Testing

- In-Circuit Testing (ICT)

- Functional Testing

These testing and inspection methods help identify any defects or issues early in the manufacturing process, reducing the risk of product failures and ensuring customer satisfaction.

PCB-UK’s Services and Capabilities

PCB Fabrication Capabilities

PCB-UK offers a wide range of PCB fabrication capabilities to meet the diverse needs of its customers. These capabilities include:

| Capability | Description |

|---|---|

| Layer Count | Up to 30 layers |

| Material Types | FR-4, High Tg FR-4, Rogers, Polyimide, Aluminum, Copper |

| Minimum Line Width/Spacing | 3 mil (0.075 mm) |

| Minimum Hole Size | 4 mil (0.1 mm) |

| Copper Thickness | 0.5 oz to 6 oz |

| Solder Mask | LPI, Dry Film |

| Surface Finishes | HASL, ENIG, OSP, Immersion Silver, Immersion Tin |

| PCB Thickness | 0.2 mm to 6 mm |

PCB Assembly Services

In addition to PCB fabrication, PCB-UK provides comprehensive PCB assembly services. The company’s assembly capabilities include:

- Surface Mount Technology (SMT) Assembly

- Through-Hole Technology (THT) Assembly

- Mixed Technology (SMT and THT) Assembly

- BGA (Ball Grid Array) and QFN (Quad Flat No-lead) Assembly

- Automated Optical Inspection (AOI)

- X-ray Inspection

- Functional Testing

- Box Build and System Integration

Rapid Prototyping and Low-Volume Production

PCB-UK understands the importance of fast turnaround times for prototyping and low-volume production. The company offers expedited services for quick-turn prototypes, allowing customers to test and validate their designs quickly.

PCB-UK’s rapid prototyping services include:

- 24-hour turnaround for simple PCBs

- 48-hour turnaround for complex PCBs

- Prototype quantities from 1 to 100 pieces

- Design for Manufacturing (DFM) feedback and support

High-Volume Production

For customers requiring high-volume production, PCB-UK has the capacity and expertise to handle large-scale orders. The company’s state-of-the-art facilities and streamlined processes ensure consistent quality and on-time delivery for high-volume projects.

PCB-UK’s high-volume production capabilities include:

- Automated SMT lines

- Multi-shift operation

- Strict quality control and traceability

- Flexible manufacturing for product variations

- Inventory management and just-in-time (JIT) delivery

PCB-UK’s Industries Served

PCB-UK serves a wide range of industries, providing tailored PCB solutions to meet the specific requirements of each sector. Some of the key industries served by PCB-UK include:

Automotive

PCB-UK manufactures high-reliability PCBs for automotive applications, such as engine control units (ECUs), infotainment systems, and advanced driver assistance systems (ADAS). The company’s Automotive PCBs are designed to withstand harsh environmental conditions and meet stringent quality and safety standards.

Aerospace and Defense

PCB-UK provides advanced PCB solutions for the aerospace and defense industry, including avionics, satellite communication, and Military Electronics. The company’s PCBs are manufactured to meet the rigorous requirements of aerospace and defense standards, such as MIL-PRF-31032 and IPC-6012 Class 3.

Medical

PCB-UK offers PCB manufacturing services for medical devices and equipment, such as patient monitors, diagnostic instruments, and implantable devices. The company’s medical PCBs are manufactured in compliance with ISO 13485 and FDA regulations, ensuring the highest levels of quality and reliability.

Industrial

PCB-UK provides robust PCB solutions for industrial applications, such as process control, automation, and power electronics. The company’s industrial PCBs are designed to operate reliably in harsh environments, withstanding extreme temperatures, vibrations, and chemical exposure.

Consumer Electronics

PCB-UK manufactures high-quality PCBs for a wide range of consumer electronics products, including smartphones, tablets, wearables, and IoT devices. The company’s advanced manufacturing capabilities enable the production of compact, high-density PCBs with fast turnaround times.

PCB-UK’s Customer Support and Service

Technical Support

PCB-UK provides comprehensive technical support to assist customers throughout the PCB design and manufacturing process. The company’s experienced engineers offer guidance on PCB design, material selection, and manufacturability to ensure optimal results.

Customers can access PCB-UK’s technical support through various channels, including:

- Telephone support

- Email support

- Online ticketing system

- On-site technical meetings

Design for Manufacturing (DFM) Feedback

PCB-UK offers Design for Manufacturing (DFM) feedback to help customers optimize their PCB designs for manufacturability and cost-effectiveness. The company’s DFM services include:

- Design rule checks (DRC)

- Layer stackup optimization

- Signal integrity analysis

- Thermal analysis

- Component placement and routing optimization

By incorporating DFM feedback early in the design process, customers can avoid potential manufacturing issues and reduce the time and cost of PCB production.

Flexible Ordering and Delivery Options

PCB-UK offers flexible ordering and delivery options to meet the diverse needs of its customers. Customers can place orders online, by email, or through a dedicated account manager. The company accepts various payment methods, including credit cards, bank transfers, and purchase orders.

PCB-UK provides a range of delivery options, including:

- Standard shipping

- Express shipping

- Overnight shipping

- International shipping

- Consignment stocking and just-in-time (JIT) delivery

Customers can track their orders online and receive real-time updates on the status of their PCBs throughout the manufacturing and shipping process.

Frequently Asked Questions (FAQ)

-

What is the minimum order quantity (MOQ) for PCBs at PCB-UK?

PCB-UK has no minimum order quantity (MOQ) for PCB fabrication and assembly. Customers can order as few as one piece for prototyping or small-scale production. -

How long does it take to manufacture a PCB at PCB-UK?

The lead time for PCB manufacturing depends on the complexity of the design and the quantity ordered. For standard PCBs, PCB-UK offers lead times as short as 24 hours for prototypes and 5-7 days for production quantities. Express services are available for urgent requirements. -

What file formats does PCB-UK accept for PCB design submission?

PCB-UK accepts various PCB design file formats, including Gerber (RS-274X), ODB++, IPC-2581, and Excellon drill files. The company also accepts native CAD files from popular EDA tools, such as Altium Designer, Cadence OrCAD, and Mentor Graphics PADS. -

Does PCB-UK offer PCB design services?

Yes, PCB-UK offers PCB design services for customers who require assistance with PCB layout and design. The company’s experienced design team uses industry-standard EDA tools and follows best practices to ensure optimal PCB performance and manufacturability. -

What certifications and quality standards does PCB-UK adhere to?

PCB-UK is ISO 9001:2015 certified and follows IPC standards for PCB manufacturing and assembly, including IPC-A-600, IPC-6012, IPC-A-610, and IPC-J-STD-001. The company also complies with industry-specific standards, such as ISO 13485 for medical devices and MIL-PRF-31032 for military electronics.

Conclusion

PCB-UK is a leading PCB manufacturer in the United Kingdom, offering high-quality PCB fabrication and assembly services for a wide range of industries. With state-of-the-art facilities, experienced professionals, and a commitment to quality and customer satisfaction, PCB-UK is well-positioned to meet the diverse PCB requirements of its customers.

From rapid prototyping to high-volume production, PCB-UK provides a comprehensive range of PCB solutions, backed by technical expertise, flexible ordering options, and exceptional customer support. By partnering with PCB-UK, customers can benefit from reliable, cost-effective, and high-performance PCBs that drive innovation and success in their respective markets.

Leave a Reply