Types of PCB Assembly

There are three main types of PCB assembly: through-hole assembly, surface mount assembly, and mixed assembly.

Through-Hole Assembly

Through-hole assembly is the traditional method of PCB assembly. It involves inserting the leads of electronic components through holes drilled in the PCB and soldering them to the other side of the board. This method is suitable for larger components and provides a strong mechanical connection. However, it is slower and more labor-intensive compared to surface mount assembly.

Surface Mount Assembly

Surface mount assembly (SMT) is a more modern and efficient method of PCB assembly. It involves placing electronic components directly onto the surface of the PCB and soldering them using a reflow oven. SMT allows for smaller component sizes and higher component density, resulting in more compact and lightweight PCBs. It is also faster and more automated compared to through-hole assembly.

Mixed Assembly

Mixed assembly combines both through-hole and surface mount techniques on a single PCB. This method is used when certain components are not available in surface mount packages or when specific design requirements call for through-hole components. Mixed assembly provides the benefits of both methods but requires careful planning and design to ensure compatibility.

PCB Assembly Process

The PCB assembly process involves several stages, each requiring precision and attention to detail. The typical steps in the PCB assembly process are as follows:

-

Solder Paste Application: Solder paste, a mixture of tiny solder particles and flux, is applied to the PCB pads using a stencil or screen printing process. The solder paste holds the components in place during the reflow process.

-

Component Placement: Electronic components are placed onto the PCB using automated pick-and-place machines or manual placement for through-hole components. The machines precisely position the components based on the PCB design files.

-

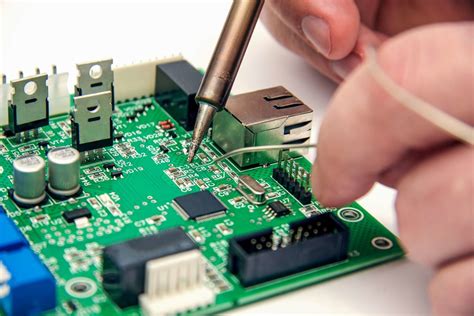

Reflow Soldering: The PCB with the placed components is passed through a reflow oven. The oven heats the PCB to a specific temperature profile, melting the solder paste and creating a permanent electrical and mechanical connection between the components and the PCB pads.

-

Inspection and Testing: After the reflow process, the assembled PCB undergoes visual inspection and automated optical inspection (AOI) to detect any defects or misaligned components. Functional testing is also performed to ensure the PCB operates as intended.

-

Cleaning and Finishing: The assembled PCB is cleaned to remove any residual flux or contaminants. Additional finishing steps, such as conformal coating or potting, may be applied depending on the specific requirements of the PCB.

Benefits of Outsourcing PCB Assembly

Outsourcing PCB assembly to professional services offers several benefits for companies and individuals seeking high-quality and efficient electronics manufacturing. Some of the key benefits include:

Cost Savings

Outsourcing PCB assembly eliminates the need for significant capital investment in specialized equipment and facilities. PCB assembly service providers have the necessary infrastructure and expertise to handle large-scale production, resulting in cost savings through economies of scale.

Faster Time-to-Market

Professional PCB assembly services have streamlined processes and automated equipment that enable faster production times. This allows companies to bring their products to market more quickly, gaining a competitive edge in the industry.

Access to Expertise and Technology

PCB assembly service providers have a team of experienced engineers and technicians who are well-versed in the latest assembly techniques and technologies. They can provide valuable insights and recommendations to optimize PCB designs for manufacturability and reliability.

Quality Assurance

Reputable PCB assembly services adhere to strict quality control standards and have rigorous testing procedures in place. They employ advanced inspection techniques, such as AOI and X-ray inspection, to ensure the assembled PCBs meet the required specifications and are free from defects.

Flexibility and Scalability

Outsourcing PCB assembly allows companies to scale their production based on demand without the need to invest in additional equipment or personnel. PCB assembly services can handle projects of varying quantities, from prototypes to mass production, providing flexibility to meet changing market needs.

Choosing the Right PCB Assembly Service

When selecting a PCB assembly service provider, several factors should be considered to ensure a successful partnership:

-

Technical Capabilities: Evaluate the service provider’s technical capabilities, including their experience with different types of PCB assembly, the equipment they use, and their ability to handle complex designs.

-

Quality Standards: Look for a service provider that adheres to industry-recognized quality standards, such as ISO 9001 or IPC Standards. Inquire about their quality control processes and certifications.

-

Turnaround Time: Consider the service provider’s typical turnaround times and their ability to meet your project deadlines. Faster turnaround times can be crucial for time-sensitive projects.

-

Communication and Support: Effective communication is essential for a successful PCB assembly project. Choose a service provider that is responsive, proactive in communication, and offers dedicated support throughout the project lifecycle.

-

Cost and Value: While cost is an important factor, it should not be the sole deciding factor. Consider the overall value provided by the service provider, including their quality, reliability, and additional services such as design support or supply chain management.

PCB Assembly Technologies and Trends

The PCB assembly industry is constantly evolving, driven by advancements in technology and changing market demands. Some of the notable technologies and trends in PCB assembly include:

Miniaturization and High-Density Interconnect (HDI)

The demand for smaller and more compact electronic devices has led to the miniaturization of PCBs and the adoption of HDI technologies. HDI PCBs feature finer trace widths, smaller via sizes, and higher layer counts, enabling higher component density and improved signal integrity.

Flexible and Rigid-Flex PCBs

Flexible PCBs and rigid-flex PCBs are gaining popularity in applications that require flexibility, such as wearable devices and automotive electronics. These PCBs can bend and conform to different shapes, offering design flexibility and improved reliability in dynamic environments.

Advanced Packaging Technologies

Advanced packaging technologies, such as ball grid array (BGA), chip-scale packaging (CSP), and package-on-package (PoP), are being increasingly used in PCB assembly. These technologies enable higher interconnect density, improved electrical performance, and reduced package size.

Automation and Industry 4.0

The PCB assembly industry is embracing automation and Industry 4.0 technologies to improve efficiency, quality, and traceability. Automated assembly lines, robotics, and data-driven manufacturing processes are being implemented to optimize production and reduce human errors.

Frequently Asked Questions (FAQ)

-

What is the difference between PCB fabrication and PCB assembly?

PCB fabrication is the process of manufacturing the bare printed circuit board, including the creation of conductive layers, drilling of holes, and application of solder mask and silkscreen. PCB assembly, on the other hand, involves the placement and soldering of electronic components onto the fabricated PCB to create a functional electronic assembly. -

What are the common file formats used in PCB assembly?

The most common file formats used in PCB assembly are Gerber files (RS-274X) for PCB fabrication data and pick-and-place files (e.g., CSV or ASCII) for component placement data. Other relevant files include bill of materials (BOM), assembly drawings, and test specifications. -

What is the typical turnaround time for PCB assembly?

The turnaround time for PCB assembly varies depending on the complexity of the design, the quantity ordered, and the service provider’s capacity. Typical turnaround times range from a few days for prototype quantities to several weeks for large production runs. Rush services may be available for time-critical projects, but they often come at a premium cost. -

How can I ensure the quality of my assembled PCBs?

To ensure the quality of your assembled PCBs, choose a reputable PCB assembly service provider with a proven track record of quality and reliability. Clearly communicate your quality requirements and specifications, and request detailed information about their quality control processes and certifications. Additionally, consider requesting a first article inspection (FAI) or a sample run to verify the quality before proceeding with full production. -

What should I consider when designing a PCB for assembly?

When designing a PCB for assembly, consider factors such as component selection, pad sizes, spacing, and orientation to ensure manufacturability and assembly compatibility. Follow the design guidelines provided by your chosen PCB assembly service provider and adhere to industry standards such as IPC-A-610 for acceptability criteria. Conduct a design for manufacturing (DFM) review to identify and address any potential assembly issues early in the design process.

Conclusion

PCB assembly is a critical process in the electronics manufacturing industry, transforming Bare PCBs into functional electronic devices. Understanding the types of PCB assembly, the process involved, and the benefits of outsourcing to professional services can help companies and individuals make informed decisions when it comes to their PCB assembly needs.

By leveraging the expertise and capabilities of PCB assembly service providers, businesses can achieve cost savings, faster time-to-market, and high-quality results. As the electronics industry continues to evolve, staying up-to-date with the latest PCB assembly technologies and trends is essential for staying competitive in the market.

When selecting a PCB assembly service provider, carefully consider factors such as technical capabilities, quality standards, turnaround time, communication, and overall value. By partnering with the right service provider and following best practices in PCB design and assembly, you can ensure the success of your electronic products and drive innovation in your industry.

| PCB Assembly Type | Characteristics | Suitable Applications |

|---|---|---|

| Through-Hole Assembly | – Strong mechanical connection – Larger components – Slower and more labor-intensive |

– High-power devices – Connectors – Transformers |

| Surface Mount Assembly | – Smaller component sizes – Higher component density – Faster and more automated |

– Consumer electronics – Wireless devices – Wearables |

| Mixed Assembly | – Combines through-hole and surface mount techniques – Provides benefits of both methods – Requires careful planning and design |

– Complex designs – Specific component requirements – Legacy components |

Leave a Reply