What is ENIG?

Electroless Nickel Immersion Gold (ENIG) is a surface finishing process used in the manufacture of printed circuit boards (PCBs). It involves the deposition of a thin layer of nickel followed by a thin layer of gold on the copper pads of the PCB. The nickel layer acts as a barrier to prevent the diffusion of copper into the gold layer, while the gold layer provides excellent solderability and protection against oxidation.

Advantages of ENIG

- Excellent solderability

- Good oxidation resistance

- Flat surface finish

- Suitable for fine-pitch components

- Compatible with a wide range of soldering processes

Disadvantages of ENIG

- Higher cost compared to other surface finishes

- Possibility of “black pad” formation due to excessive phosphorus content in the nickel layer

- Potential for nickel corrosion in harsh environments

The ENIG Process

The ENIG process consists of several steps:

- Cleaning: The PCB is cleaned to remove any contaminants or oxides from the copper surface.

- Microetching: A mild etching process is used to roughen the copper surface, improving adhesion of the subsequent layers.

- Electroless Nickel Plating: The PCB is immersed in an electroless nickel plating solution, which deposits a thin layer of nickel (typically 3-6 µm) on the copper surface.

- Immersion Gold Plating: The nickel-plated PCB is then immersed in an immersion gold plating solution, which deposits a thin layer of gold (typically 0.05-0.2 µm) on the nickel surface.

- Rinsing and Drying: The PCB is rinsed with deionized water and dried.

Factors Affecting ENIG Performance

Several factors can affect the performance of ENIG surface finish:

- Nickel Layer Thickness: A thicker nickel layer provides better barrier properties but may lead to increased stress in the deposit.

- Gold Layer Thickness: A thicker gold layer provides better oxidation resistance but may increase the cost of the process.

- Phosphorus Content in Nickel Layer: Higher phosphorus content improves the corrosion resistance of the nickel layer but may lead to “black pad” formation.

- Bath Composition and Control: Proper control of the plating bath composition and operating parameters is essential for achieving consistent and high-quality ENIG finishes.

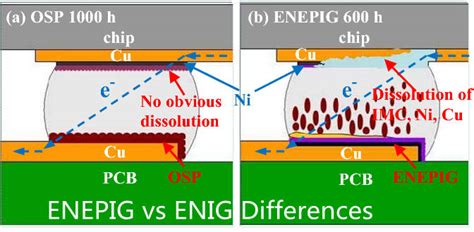

ENIG vs. Other Surface Finishes

ENIG is one of several surface finishes used in PCB manufacturing. Other common surface finishes include:

- Hot Air Solder Leveling (HASL): A tin-lead or Lead-Free Solder is applied to the copper pads and then leveled using hot air.

- Immersion Silver (IAg): A thin layer of silver is deposited on the copper pads using an immersion plating process.

- Organic Solderability Preservative (OSP): A thin organic coating is applied to the copper pads to prevent oxidation.

The choice of surface finish depends on various factors such as cost, solderability requirements, shelf life, and compatibility with the assembly process.

| Surface Finish | Solderability | Shelf Life | Fine-Pitch Compatibility | Cost |

|---|---|---|---|---|

| ENIG | Excellent | Excellent | Excellent | High |

| HASL | Good | Good | Limited | Low |

| IAg | Excellent | Good | Excellent | Moderate |

| OSP | Good | Limited | Good | Low |

Applications of ENIG

ENIG surface finish is widely used in various applications, including:

- High-reliability electronics (e.g., aerospace, military, medical)

- Fine-pitch components (e.g., BGAs, CSPs)

- Wire Bonding applications

- Press-fit connectors

- Flexible and Rigid-Flex PCBs

Quality Control and Testing

To ensure the quality and reliability of ENIG surface finish, several tests and inspections are performed:

- Visual Inspection: The PCB surface is visually inspected for any defects, such as discoloration, blisters, or pits.

- Thickness Measurement: The thickness of the nickel and gold layers is measured using X-ray fluorescence (XRF) or cross-sectional analysis.

- Solderability Test: The solderability of the ENIG surface is evaluated using a wetting balance test or a dip-and-look test.

- Adhesion Test: The adhesion of the nickel and gold layers to the copper substrate is tested using a peel test or a tape test.

- Porosity Test: The porosity of the nickel layer is assessed using a steam aging test or a nitric acid vapor test.

Troubleshooting ENIG Issues

Some common issues encountered with ENIG surface finish and their possible causes:

- Black Pad: Excessive phosphorus content in the nickel layer can lead to the formation of a brittle nickel-phosphorus intermetallic compound, resulting in a “black pad” appearance and poor solderability. This can be prevented by controlling the phosphorus content and the plating bath parameters.

- Nickel Corrosion: In harsh environments, the nickel layer may be susceptible to corrosion, leading to a loss of solderability and reliability. This can be mitigated by ensuring proper process control and using a thicker gold layer.

- Poor Adhesion: Inadequate surface preparation or contamination can result in poor adhesion of the nickel and gold layers to the copper substrate. This can be prevented by thorough cleaning and microetching of the copper surface prior to plating.

FAQ

-

Q: What is the typical thickness of the nickel and gold layers in ENIG?

A: The typical thickness of the nickel layer is 3-6 µm, while the gold layer is usually 0.05-0.2 µm thick. -

Q: How does ENIG compare to HASL in terms of cost?

A: ENIG is generally more expensive than HASL due to the higher cost of gold and the more complex plating process. -

Q: Can ENIG be used for wire bonding applications?

A: Yes, ENIG is suitable for wire bonding applications due to its flat surface finish and good oxidation resistance. -

Q: What is the shelf life of ENIG surface finish?

A: ENIG has an excellent shelf life, typically 12 months or more, due to the oxidation resistance provided by the gold layer. -

Q: How can “black pad” formation be prevented in ENIG?

A: “Black pad” formation can be prevented by controlling the phosphorus content in the nickel layer and optimizing the plating bath parameters.

In conclusion, ENIG is a versatile and reliable surface finish that offers excellent solderability, oxidation resistance, and compatibility with fine-pitch components. By understanding the ENIG process, its advantages and limitations, and the factors affecting its performance, PCB Manufacturers and designers can effectively utilize this surface finish in a wide range of applications. Proper process control, quality testing, and troubleshooting are essential for ensuring the consistency and reliability of ENIG surface finish.

Leave a Reply