Introduction to Electronic Assembly

Electronic assembly is the process of assembling electronic components and parts onto a printed circuit board (PCB) to create a functional electronic device. This process involves a range of techniques, technologies, and procedures that have evolved over the years to keep pace with the increasing complexity and miniaturization of electronic devices.

In this article, we will delve into the world of electronic assembly, exploring its various aspects, trends, and challenges. We will also discuss the latest advancements in this field and their impact on the electronics industry.

Types of Electronic Assembly

There are three main types of electronic assembly:

- Through-Hole Assembly (THA): This is the traditional method of electronic assembly, where component leads are inserted through holes in the PCB and soldered on the opposite side. THA is still used for larger components and in applications where high mechanical strength is required.

- Surface Mount Assembly (SMA): In this method, components are placed directly on the surface of the PCB and soldered using reflow or wave soldering techniques. SMA allows for higher component density and smaller device sizes compared to THA.

- Mixed Technology Assembly (MTA): This approach combines both THA and SMA techniques on a single PCB, allowing for the use of a wider range of components and greater design flexibility.

Electronic Assembly Process

The electronic assembly process typically involves the following steps:

- PCB Fabrication: The PCB is designed and manufactured according to the device specifications.

- Solder Paste Application: Solder paste, a mixture of tiny solder particles and flux, is applied to the PCB pads using a stencil or screen printing process.

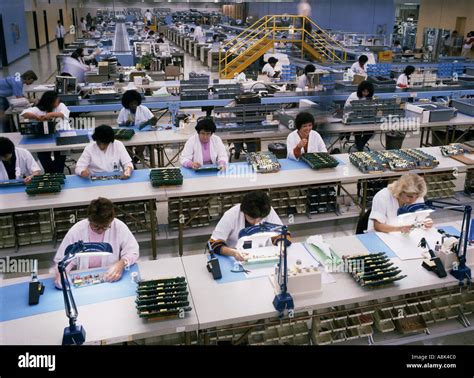

- Component Placement: Electronic components are placed on the PCB either manually or using automated pick-and-place machines.

- Soldering: The PCB with components is heated in a reflow oven or passed through a wave soldering machine to melt the solder and create electrical connections.

- Inspection and Testing: The assembLED PCB undergoes visual inspection, Automated Optical Inspection (AOI), and functional testing to ensure quality and performance.

- Conformal Coating and Encapsulation: In some cases, the assembled PCB is coated with a protective layer or encapsulated to enhance its durability and resistance to environmental factors.

Advancements in Electronic Assembly Technology

The electronic assembly industry has witnessed significant advancements in recent years, driven by the need for faster, more efficient, and cost-effective production processes. Some of these advancements include:

Automated Assembly Equipment

Modern electronic assembly heavily relies on automated equipment, such as pick-and-place machines, reflow ovens, and inspection systems. These machines offer high precision, speed, and consistency, enabling the assembly of complex devices with minimal human intervention.

| Equipment | Function | Benefits |

|---|---|---|

| Pick-and-Place Machines | Accurately place components on the PCB | High speed, precision, and consistency |

| Reflow Ovens | Melt solder to create electrical connections | Controlled heating, uniform solder joints |

| Automated Optical Inspection (AOI) | Detect assembly defects and component placement errors | Fast, accurate, and non-destructive testing |

Advanced Soldering Techniques

Soldering techniques have evolved to accommodate the increasing complexity and miniaturization of electronic devices. Some of the advanced soldering techniques include:

- Reflow Soldering: This technique involves applying solder paste to the PCB pads, placing components, and then heating the entire assembly in a reflow oven to melt the solder and create connections.

- Selective Soldering: This method allows for the soldering of specific components or areas on a PCB, using a localized soldering tool or nozzle. Selective soldering is useful for assemblies with a mix of through-hole and surface mount components.

- Vapor Phase Soldering: In this technique, the PCB Assembly is heated in a saturated vapor of a heat transfer fluid, which condenses on the assembly and creates a uniform temperature distribution for soldering.

3D Printing in Electronic Assembly

3D printing technology has found applications in electronic assembly, particularly in the creation of custom enclosures, fixtures, and even PCBs. 3D printing allows for rapid prototyping, design iterations, and the production of complex geometries that would be difficult or impossible with traditional manufacturing methods.

Robotics and AI in Electronic Assembly

The integration of robotics and artificial intelligence (AI) in electronic assembly has enabled the automation of complex tasks and improved overall production efficiency. Collaborative robots (cobots) can work alongside human operators, performing tasks such as component handling, soldering, and inspection. AI-powered systems can analyze data from various sensors and inspection systems to optimize the assembly process and detect potential issues in real-time.

Challenges in Electronic Assembly

Despite the advancements in technology, the electronic assembly industry faces several challenges:

- Miniaturization: As electronic devices become smaller and more compact, the assembly process becomes more challenging, requiring higher precision and accuracy.

- Component Obsolescence: The rapid pace of technological change often leads to the obsolescence of electronic components, making it difficult for manufacturers to maintain long-term product support.

- Supply Chain Disruptions: Electronic assembly relies on a global supply chain for components and materials, which can be disrupted by various factors, such as natural disasters, geopolitical events, or pandemics.

- Skilled Labor Shortage: The increasing complexity of electronic assembly requires a skilled workforce, but there is often a shortage of qualified technicians and engineers in the industry.

- Environmental Concerns: The electronic assembly industry faces pressure to adopt environmentally friendly practices, such as the use of lead-free solders and the proper disposal of electronic waste.

Future Trends in Electronic Assembly

Looking ahead, the electronic assembly industry is poised for further innovation and growth, driven by several key trends:

- Industry 4.0: The integration of advanced technologies, such as the Internet of Things (IoT), big data analytics, and cloud computing, will enable smarter, more connected, and more efficient electronic assembly processes.

- Flexible and Wearable Electronics: The demand for flexible and wearable electronic devices will drive the development of new materials, assembly techniques, and packaging solutions.

- Sustainable Electronics: There will be a growing emphasis on sustainable electronic assembly practices, including the use of eco-friendly materials, energy-efficient processes, and circular economy principles.

- Additive Manufacturing: The integration of additive manufacturing techniques, such as 3D printing, will enable the creation of novel electronic structures and the production of customized electronic devices on demand.

FAQ

- Q: What is the difference between through-hole and surface mount assembly?

A: Through-hole assembly involves inserting component leads through holes in the PCB and soldering them on the opposite side, while surface mount assembly involves placing components directly on the surface of the PCB and soldering them using reflow or wave soldering techniques. - Q: What are the benefits of automated assembly equipment?

A: Automated assembly equipment, such as pick-and-place machines and reflow ovens, offers high precision, speed, and consistency, enabling the assembly of complex devices with minimal human intervention. - Q: How has 3D printing technology been applied in electronic assembly?

A: 3D printing technology has been used in electronic assembly for creating custom enclosures, fixtures, and even PCBs, allowing for rapid prototyping, design iterations, and the production of complex geometries. - Q: What are some of the challenges faced by the electronic assembly industry?

A: The electronic assembly industry faces challenges such as miniaturization, component obsolescence, supply chain disruptions, skilled labor shortages, and environmental concerns. - Q: What are some of the future trends in electronic assembly?

A: Future trends in electronic assembly include the integration of Industry 4.0 technologies, the growth of flexible and wearable electronics, an emphasis on sustainable electronics, and the increased use of additive manufacturing techniques.

Conclusion

Electronic assembly is a dynamic and constantly evolving field that plays a crucial role in the production of the electronic devices we rely on in our daily lives. From the traditional through-hole assembly to the advanced surface mount techniques, the industry has adapted to the changing demands of the market and the increasing complexity of electronic devices.

Advancements in automation, soldering techniques, 3D printing, robotics, and AI have revolutionized the electronic assembly process, enabling faster, more efficient, and more cost-effective production. However, the industry also faces challenges, such as miniaturization, component obsolescence, supply chain disruptions, skilled labor shortages, and environmental concerns.

Looking to the future, the electronic assembly industry is poised for further growth and innovation, driven by trends such as Industry 4.0, flexible and wearable electronics, sustainable electronics, and additive manufacturing. As these trends shape the industry, electronic assembly will continue to play a vital role in bringing new and exciting electronic devices to market, driving technological progress and improving our quality of life.

Leave a Reply