ALL ABOUT FLEX PCB

-

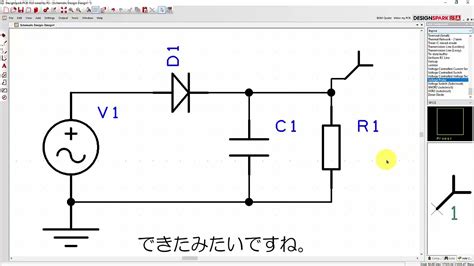

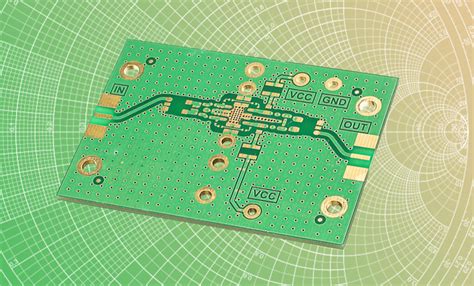

DesignSpark PCB Design Software for Windows PCs

Posted by

–

Read more: DesignSpark PCB Design Software for Windows PCs

Read more: DesignSpark PCB Design Software for Windows PCsKey Features of DesignSpark PCB 1. Intuitive User Interface DesignSpark PCB boasts a clean and intuitive user interface that makes navigating the software a breeze. The well-organized layout and customizable toolbars allow users to access frequently used tools and commands quickly, enhancing productivity and efficiency. 2. Schematic Capture Creating schematics […]

-

Isola Adds PCB Certification

Posted by

–

Read more: Isola Adds PCB Certification

Read more: Isola Adds PCB CertificationLeading Laminate Manufacturer Expands Offerings with Printed Circuit Board Certification Isola, a global leader in the manufacture of high-performance laminate materials for printed circuit boards (PCBs), has recently announced the addition of PCB certification services to its portfolio. This strategic move positions Isola as a one-stop solution provider for the […]

-

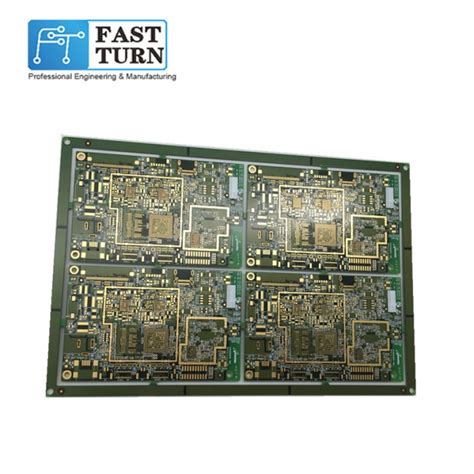

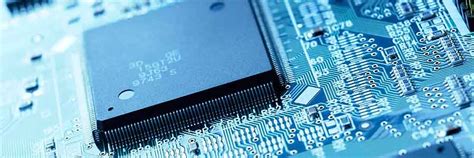

How to remove the IC block from the PCB

Posted by

–

Read more: How to remove the IC block from the PCB

Read more: How to remove the IC block from the PCBIntroduction to IC block removal Integrated Circuit (IC) blocks are essential components of Printed Circuit Boards (PCBs) that perform various functions in electronic devices. However, there may be instances when you need to remove an IC block from a PCB, such as for replacement, repair, or upgrades. This article will […]

-

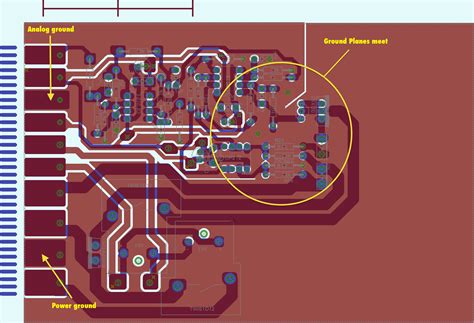

Grounding of the Printed Circuit Boards

Posted by

–

Read more: Grounding of the Printed Circuit Boards

Read more: Grounding of the Printed Circuit BoardsIntroduction to PCB Grounding Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing a platform for interconnecting electronic components and enabling the functioning of complex circuits. One critical aspect of PCB design is proper grounding, which ensures the stability, performance, and reliability of the electronic system. In this […]

-

RoHS Influence PCB Industry

Posted by

–

Read more: RoHS Influence PCB Industry

Read more: RoHS Influence PCB IndustryUnderstanding RoHS and Its Requirements RoHS is a directive that originated in the European Union (EU) and has since been adopted by many countries worldwide. The directive restricts the use of six hazardous substances in electrical and electronic equipment: Lead (Pb) Mercury (Hg) Cadmium (Cd) Hexavalent Chromium (Cr6+) Polybrominated Biphenyls […]

-

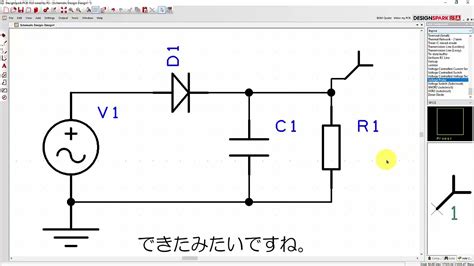

Read more: What Do You Need to Know About Turnkey PCB Assembly and EMS?

Read more: What Do You Need to Know About Turnkey PCB Assembly and EMS?Introduction to Turnkey PCB Assembly Turnkey PCB (printed circuit board) assembly refers to the complete end-to-end process of fabricating PCBs from design through final assembly by a single vendor. In a turnkey PCB Assembly service, the provider handles every step including: PCB design review and optimization Prototyping Component sourcing and […]

-

PCB Routing Tips for Beginners

Posted by

–

Read more: PCB Routing Tips for Beginners

Read more: PCB Routing Tips for BeginnersIntroduction to PCB Routing PCB routing is the process of creating electrical connections between components on a printed circuit board (PCB). It is a crucial step in the PCB design process, as it directly affects the functionality, reliability, and manufacturability of the final product. For beginners, PCB routing can be […]

-

The Control of Light and Moisture In PCB Factory

Posted by

–

Read more: The Control of Light and Moisture In PCB Factory

Read more: The Control of Light and Moisture In PCB FactoryIntroduction to PCB Environmental Control Printed Circuit Boards (PCBs) are essential components in modern electronics. The manufacturing process of PCBs requires precise control over various environmental factors to ensure high quality and reliability. Two critical factors that significantly impact PCB production are light and moisture. In this article, we will […]

-

Holiday Notice of The Dragon Boat Festival

Posted by

–

Read more: Holiday Notice of The Dragon Boat Festival

Read more: Holiday Notice of The Dragon Boat FestivalHistory of the Dragon Boat Festival The Dragon Boat Festival has a rich history that dates back over 2,000 years. The most well-known legend associated with the festival is that of Qu Yuan, a patriotic poet who lived during the Warring States period (475-221 BC). Qu Yuan was a minister […]

-

Read more: New Cadence Allegro PCB design next generation productivity platform change

Read more: New Cadence Allegro PCB design next generation productivity platform changeIntroduction to Allegro PCB Cadence Allegro PCB Designer is a powerful and comprehensive PCB design solution that enables engineers to create complex, high-quality PCB layouts with ease. With its advanced features and intuitive interface, Allegro PCB Designer streamlines the PCB design process, from schematic capture to final layout and manufacturing. […]