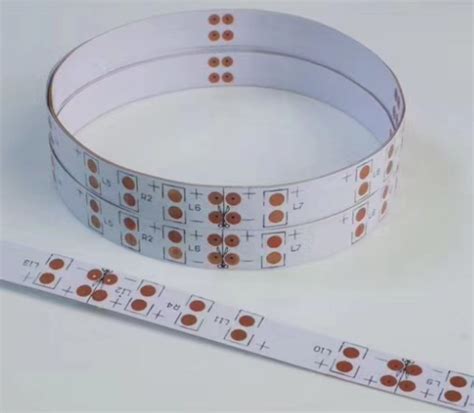

What is a Flexible PCB LED Strip?

A flexible PCB LED strip is a type of printed circuit board that uses a flexible substrate material instead of the traditional rigid FR4 material. The flexible substrate allows the PCB to bend and flex without damaging the components or connections. LEDs are mounted on the flexible PCB, creating a strip of lights that can be used for a variety of applications, such as:

- Automotive lighting

- Architectural lighting

- Display lighting

- Wearable electronics

- Medical devices

Flexible PCB LED strips offer several benefits over rigid PCBs, including:

- Greater flexibility and durability

- Ability to conform to curved surfaces

- Reduced weight and thickness

- Improved shock and vibration resistance

- Increased design freedom

Challenges in Designing Flexible PCB LED Strips

While flexible PCB LED strips offer many benefits, designing and manufacturing them can be challenging. Some of the key challenges include:

Material Selection

Choosing the right flexible substrate material is critical for the success of your design. The material must be able to withstand the bending and flexing without cracking or breaking. Common flexible substrate materials include:

| Material | Description | Advantages | Disadvantages |

|---|---|---|---|

| Polyimide (PI) | A high-temperature resistant polymer film | Excellent thermal stability, good chemical resistance | Expensive, difficult to process |

| Polyethylene Terephthalate (PET) | A thermoplastic polymer resin | Low cost, good flexibility, transparency | Limited temperature resistance |

| Flexible Copper Clad Laminate (FCCL) | A Copper Foil laminated to a flexible substrate | Good conductivity, high flexibility | Limited thermal stability |

Circuit Design

Designing the circuit for a flexible PCB LED strip requires careful consideration of the bending and flexing that the strip will undergo. The circuit must be designed to minimize stress on the components and connections during bending. Some key design considerations include:

- Using smaller components to reduce stress

- Placing components away from bend areas

- Using strain relief features, such as slots or cutouts

- Using flexible Solder mask and coverlay materials

LED Selection

Choosing the right LEDs for your flexible PCB LED strip is important for achieving the desired light output and reliability. Some key considerations when selecting LEDs include:

- Brightness and color temperature

- Viewing angle

- Size and package type

- Forward voltage and current

- Thermal management requirements

Manufacturing Process

Manufacturing flexible PCB LED strips requires specialized equipment and processes compared to traditional rigid PCBs. Some key manufacturing considerations include:

- Using flexible PCB materials and adhesives

- Handling and processing thin, flexible materials

- Ensuring proper alignment and registration of layers

- Using specialized soldering techniques, such as reflow or vapor phase soldering

- Testing and inspecting for reliability and durability

Solutions for Designing Flexible PCB LED Strips

Despite the challenges, there are several solutions available for designing and manufacturing flexible PCB LED strips:

Use Flexible PCB design software

Using specialized flexible PCB design software can help streamline the design process and ensure that your design is optimized for flexibility and reliability. Some popular flexible PCB design software includes:

| Software | Description |

|---|---|

| Altium Designer | A comprehensive PCB design software with flexible PCB design capabilities |

| Cadence Allegro | A flexible PCB design solution with advanced routing and simulation tools |

| Zuken CR-8000 | A multi-board PCB design platform with flexible PCB design features |

These software tools offer features such as 3D modeling, bend simulation, and DFM checks to help ensure that your design is manufacturable and reliable.

Work with an Experienced Flexible PCB Manufacturer

Working with an experienced flexible PCB manufacturer can help ensure that your design is successfully manufactured. Look for a manufacturer with experience in flexible PCBs and a proven track record of quality and reliability. Some key considerations when selecting a flexible PCB manufacturer include:

- Technical capabilities and equipment

- Quality control processes

- Lead times and pricing

- Customer support and communication

Use Proven Flexible PCB Materials and Components

Using proven flexible PCB materials and components can help ensure the reliability and durability of your design. Work with reputable suppliers and choose materials and components that have been tested and validated for use in flexible PCBs. Some key materials and components to consider include:

- Flexible substrate materials (e.g., PI, PET, FCCL)

- Flexible solder mask and coverlay materials

- Flexible adhesives and encapsulants

- Flexible connectors and cables

- LEDs with proven reliability in flexible applications

Conduct Thorough Testing and Validation

Conducting thorough testing and validation of your flexible PCB LED strip design is critical for ensuring its reliability and durability in the field. Some key testing and validation activities include:

- Bend and flex testing

- Thermal cycling and shock testing

- Humidity and environmental testing

- Light output and color consistency testing

- Accelerated life testing

By conducting these tests, you can identify and address any potential issues before your design goes into production.

FAQ

What is the typical lifespan of a flexible PCB LED strip?

The lifespan of a flexible PCB LED strip depends on several factors, including the quality of the materials and components used, the operating conditions, and the design of the circuit. With proper design and manufacturing, a flexible PCB LED strip can last for 50,000 hours or more.

Can flexible PCB LED strips be cut to length?

Yes, most flexible PCB LED strips are designed to be cut to length at designated cut points along the strip. However, it is important to carefully follow the manufacturer’s instructions for cutting and sealing the ends of the strip to ensure proper operation and reliability.

How do I choose the right LED for my flexible PCB LED strip?

When choosing LEDs for your flexible PCB LED strip, consider factors such as brightness, color temperature, viewing angle, size, and power requirements. Work with a reputable LED supplier and choose LEDs that have been tested and validated for use in flexible applications.

Can flexible PCB LED strips be bent or flexed repeatedly?

Yes, flexible PCB LED strips are designed to withstand repeated bending and flexing. However, the degree of flexibility and the number of bend cycles that a strip can withstand will depend on the specific design and materials used. It is important to conduct thorough testing and validation to ensure that your design can withstand the expected use case.

How do I ensure proper thermal management for my flexible PCB LED strip?

Proper thermal management is critical for ensuring the reliability and longevity of your flexible PCB LED strip. Some key thermal management techniques include using high-quality LEDs with low thermal resistance, designing the circuit to minimize heat generation, and using thermally conductive adhesives and heatsinks to dissipate heat. It is also important to conduct thermal testing and validation to ensure that your design can operate within the specified temperature range.

Conclusion

Designing and manufacturing flexible PCB LED strips can be challenging, but with the right solutions and approach, it is possible to bring your design to reality. By using specialized design software, working with experienced manufacturers, choosing proven materials and components, and conducting thorough testing and validation, you can create a reliable and durable flexible PCB LED strip that meets your specific application requirements.

Leave a Reply