Introduction to Four-Terminal Sensing

Four-terminal sensing, also known as Kelvin sensing, is a highly accurate method for measuring low resistances in advanced printed circuit boards (PCBs). This technique is particularly useful in applications where precise resistance measurements are critical, such as in high-current circuits, high-precision analog circuits, and advanced PCB designs. By using four separate terminals for current injection and voltage measurement, four-terminal sensing eliminates the effects of lead resistance and contact resistance, resulting in highly accurate resistance measurements.

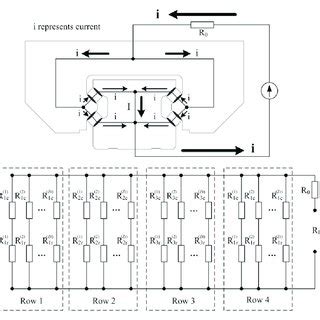

How Four-Terminal Sensing Works

In a traditional two-terminal resistance measurement, the resistance of the test leads and the contact resistance between the leads and the device under test (DUT) are included in the measurement. This can lead to significant errors when measuring low resistances, as the lead and contact resistances can be comparable to or even greater than the resistance of the DUT itself.

Four-terminal sensing overcomes this limitation by using separate pairs of terminals for current injection and voltage measurement. The current is injected through one pair of terminals, while the voltage drop across the DUT is measured using the other pair of terminals. Because the voltage measurement terminals draw very little current, the voltage drop across the lead and contact resistances is negligible, and the measured voltage accurately reflects the voltage drop across the DUT itself.

Benefits of Four-Terminal Sensing in Advanced PCB Testing

-

High Accuracy: By eliminating the effects of lead and contact resistances, four-terminal sensing provides highly accurate resistance measurements, even for low-resistance devices.

-

Improved Signal Integrity: In high-current circuits, such as power distribution networks, accurate resistance measurements are essential for ensuring proper current distribution and minimizing voltage drops. Four-terminal sensing helps to identify potential issues and optimize PCB designs for improved signal integrity.

-

Enhanced Reliability: Precise resistance measurements enable designers to identify and address potential reliability issues, such as excessive voltage drops or current crowding, which can lead to component failures or reduced performance.

-

Faster Troubleshooting: Four-terminal sensing can help to quickly identify and isolate problems in advanced PCB designs, reducing troubleshooting time and improving overall product development efficiency.

Applications of Four-Terminal Sensing in Advanced PCB Design

Power Distribution Networks

In advanced PCB designs, power distribution networks (PDNs) play a critical role in ensuring proper voltage delivery to components across the board. Accurate resistance measurements are essential for optimizing PDN designs and minimizing voltage drops, which can lead to signal integrity issues and reduced performance.

Four-terminal sensing enables designers to accurately measure the resistance of power planes, vias, and other critical components of the PDN. By identifying areas of high resistance or current crowding, designers can make informed decisions about PCB layout, copper weight, and via placement to improve power delivery and ensure reliable operation.

High-Current Circuits

High-current circuits, such as those found in power electronics or automotive applications, require careful design to ensure proper current distribution and minimize losses. Four-terminal sensing allows designers to accurately measure the resistance of high-current traces, connectors, and components, enabling them to optimize circuit layouts and select appropriate materials for improved performance and reliability.

High-Precision Analog Circuits

In high-precision analog circuits, such as those found in medical devices or scientific instrumentation, even small variations in resistance can have a significant impact on circuit performance. Four-terminal sensing enables designers to accurately characterize the resistance of critical components, such as precision resistors or printed resistors, ensuring that the circuit operates within specified tolerances.

Advanced PCB Materials

As PCB designs continue to push the boundaries of performance and miniaturization, new materials and manufacturing techniques are being developed to meet these challenges. Four-terminal sensing plays a crucial role in characterizing the electrical properties of these advanced materials, such as high-frequency laminates, embedded passives, or 3D-printed conductors.

By accurately measuring the resistance of these materials under various conditions, such as temperature or frequency, designers can optimize their properties and ensure reliable performance in advanced PCB Applications.

Implementing Four-Terminal Sensing in PCB Testing

Test Equipment

To perform four-terminal sensing measurements on a PCB, specialized test equipment is required. This typically includes a precision current source, a high-impedance voltmeter, and a four-terminal probe or fixture.

The current source is used to inject a known current through the DUT, while the voltmeter measures the voltage drop across the DUT. The four-terminal probe or fixture provides separate connections for current injection and voltage measurement, minimizing the effects of lead and contact resistances.

Test Procedures

When implementing four-terminal sensing in PCB testing, it is important to follow proper test procedures to ensure accurate and repeatable results. This includes:

-

Probe Placement: Ensure that the current injection and voltage measurement probes are placed as close to the DUT as possible, minimizing the lead lengths and reducing the effects of lead resistance.

-

Contact Resistance: Clean the probe tips and the E-Test-points-of-a-pcb/”>test points on the PCB to minimize contact resistance. Use appropriate probe tip materials and geometries to ensure reliable contact.

-

Current Levels: Select an appropriate current level for the DUT, considering its power dissipation and temperature rise. Higher currents can improve measurement accuracy but may also cause heating or damage to the DUT.

-

Measurement Averaging: To reduce the effects of noise and improve measurement stability, use averaging or filtering techniques to process the voltage measurements.

Test Fixturing

For high-volume PCB testing, custom test fixtures can be designed to facilitate four-terminal sensing measurements. These fixtures typically include:

-

Probe Pins: Precision-machined probe pins are used to make reliable contact with the test points on the PCB. The pins are typically arranged in a four-terminal configuration, with separate pins for current injection and voltage measurement.

-

PCB Alignment: The fixture includes alignment features, such as pins or brackets, to ensure precise and repeatable placement of the PCB during testing.

-

Signal Routing: The fixture routes the current and voltage signals from the probe pins to the test equipment, using shielded or twisted-pair cables to minimize noise and interference.

By using a well-designed test fixture, four-terminal sensing measurements can be performed quickly and reliably, enabling efficient testing of large numbers of PCBs.

Interpreting Four-Terminal Sensing Results

Resistance Measurements

The primary result of a four-terminal sensing measurement is the resistance of the DUT. This resistance value is calculated by dividing the measured voltage drop by the injected current:

R = V / I

where:

– R is the resistance of the DUT (in ohms)

– V is the measured voltage drop across the DUT (in volts)

– I is the injected current through the DUT (in amperes)

The resistance value obtained from a four-terminal sensing measurement is highly accurate, as it excludes the effects of lead and contact resistances.

Temperature Effects

The resistance of a conductor varies with temperature, and this effect can be significant in advanced PCB applications. Four-terminal sensing measurements can be used to characterize the temperature dependence of PCB materials and components, enabling designers to select materials with suitable temperature coefficients and to compensate for temperature effects in circuit designs.

To measure the temperature dependence of resistance, four-terminal sensing measurements can be performed at various temperatures, either by using a temperature-controlled test chamber or by applying temperature gradients to the DUT.

Frequency Effects

In High-Frequency PCB applications, the resistance of conductors can vary with frequency due to skin effect and other phenomena. Four-terminal sensing measurements can be used to characterize the frequency dependence of PCB materials and components, enabling designers to select materials with suitable high-frequency properties and to optimize circuit layouts for high-frequency performance.

To measure the frequency dependence of resistance, four-terminal sensing measurements can be performed at various frequencies, using a precision AC current source and a high-frequency voltmeter or network analyzer.

Challenges and Limitations of Four-Terminal Sensing

Probe Contact Resistance

Although four-terminal sensing eliminates the effects of lead resistance, the contact resistance between the probes and the DUT can still introduce errors in the measurement. This is particularly true when measuring very low resistances, where the contact resistance can be comparable to the DUT resistance.

To minimize contact resistance, it is important to use high-quality probes with clean, sharp tips and to ensure reliable contact between the probes and the test points on the PCB. In some cases, special probe materials or geometries may be required to achieve low contact resistance.

Thermal EMF

Thermal electromotive force (EMF) is a voltage generated by the junction of two dissimilar metals at different temperatures. In four-terminal sensing measurements, thermal EMF can introduce errors if the probe materials and the DUT materials have different Seebeck coefficients.

To minimize thermal EMF, it is important to use probe materials that are similar to the DUT materials, or to use materials with low Seebeck coefficients. In some cases, it may be necessary to use offset compensation techniques to cancel the effects of thermal EMF.

High-Frequency Effects

At high frequencies, the impedance of the test leads and the probes can introduce errors in the four-terminal sensing measurement. This is because the impedance of the leads and probes can become significant compared to the impedance of the DUT, leading to voltage drops and phase shifts that affect the measurement accuracy.

To minimize high-frequency effects, it is important to use low-impedance test leads and probes, and to minimize the lead lengths and loop areas. In some cases, it may be necessary to use specialized high-frequency test equipment, such as network analyzers or vector voltmeters, to accurately measure the impedance of the DUT at high frequencies.

FAQ

1. What is the difference between two-terminal and four-terminal sensing?

In two-terminal sensing, the same pair of leads is used to inject current and measure voltage, which includes the lead and contact resistances in the measurement. In four-terminal sensing, separate pairs of leads are used for current injection and voltage measurement, which eliminates the effects of lead and contact resistances and provides a more accurate measurement of the DUT resistance.

2. Can four-terminal sensing be used to measure capacitance or inductance?

No, four-terminal sensing is specifically designed to measure resistance. Capacitance and inductance measurements typically require different test methods, such as impedance spectroscopy or LCR meters.

3. What are the typical resistance values that can be measured with four-terminal sensing?

Four-terminal sensing is particularly useful for measuring low resistances, typically in the range of milliohms to a few ohms. However, with appropriate test equipment and fixturing, four-terminal sensing can be used to measure resistances up to several kiloohms.

4. How does contact resistance affect the accuracy of four-terminal sensing measurements?

Although four-terminal sensing eliminates the effects of lead resistance, contact resistance can still introduce errors in the measurement, particularly when measuring very low resistances. To minimize contact resistance, it is important to use high-quality probes with clean, sharp tips and to ensure reliable contact between the probes and the test points on the PCB.

5. Can four-terminal sensing be used to measure the resistance of non-PCB Components, such as cables or connectors?

Yes, four-terminal sensing can be used to measure the resistance of any conductor, including cables, connectors, or other components. However, specialized test fixtures or probes may be required to make reliable contact with the component under test.

Conclusion

Four-terminal sensing is a powerful technique for measuring low resistances in advanced PCB applications. By eliminating the effects of lead and contact resistances, four-terminal sensing provides highly accurate resistance measurements, enabling designers to optimize PCB layouts, select appropriate materials, and ensure reliable performance in high-current, high-precision, and high-frequency circuits.

To implement four-terminal sensing effectively, it is important to use appropriate test equipment, follow proper test procedures, and design suitable test fixtures. By understanding the challenges and limitations of four-terminal sensing, such as contact resistance, thermal EMF, and high-frequency effects, designers can take steps to minimize errors and ensure reliable measurement results.

As PCB designs continue to push the boundaries of performance and miniaturization, four-terminal sensing will play an increasingly important role in characterizing the electrical properties of advanced materials and ensuring the reliability of complex circuits. By leveraging the benefits of four-terminal sensing, PCB designers and manufacturers can develop innovative solutions that meet the demands of today’s most challenging applications.

Leave a Reply