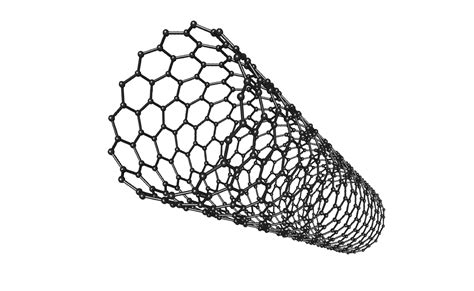

What is a Carbon Nanotube PCB?

A carbon nanotube PCB is a printed circuit board that incorporates carbon nanotubes (CNTs) into its structure. CNTs are cylindrical molecules made of carbon atoms, with diameters in the nanometer range and lengths that can reach several micrometers. These nanotubes possess exceptional electrical, thermal, and mechanical properties, making them an attractive material for PCB Applications.

Advantages of Carbon Nanotube PCBs

- High Electrical Conductivity: CNTs exhibit excellent electrical conductivity, allowing for faster signal transmission and reduced resistance in PCBs.

- Superior Thermal Management: The high thermal conductivity of CNTs enables efficient heat dissipation, preventing overheating and improving the overall reliability of the PCB.

- Enhanced Mechanical Strength: Carbon nanotubes provide exceptional mechanical strength, making the PCB more durable and resistant to physical stresses.

- Lightweight: CNTs have a low density compared to traditional PCB Materials, resulting in lighter PCBs without compromising performance.

Disadvantages of Carbon Nanotube PCBs

- Higher Cost: The production and integration of carbon nanotubes into PCBs are still relatively expensive compared to conventional PCB materials.

- Manufacturing Challenges: The process of incorporating CNTs into PCBs requires specialized equipment and techniques, which can be complex and time-consuming.

- Limited Availability: The supply chain for carbon nanotube PCBs is not as well-established as traditional PCB materials, which may lead to longer lead times and limited availability.

What is an Aluminum PCB?

An aluminum PCB is a printed circuit board that uses aluminum as the base material instead of the commonly used FR-4 (fiberglass-epoxy) substrate. Aluminum PCBs are known for their excellent thermal conductivity and heat dissipation capabilities.

Advantages of Aluminum PCBs

- Excellent Thermal Management: Aluminum has a high thermal conductivity, allowing for efficient heat dissipation and preventing the buildup of hot spots on the PCB.

- Improved Mechanical Stability: Aluminum provides a rigid and stable base for the PCB, reducing warping and improving overall mechanical stability.

- Cost-effective: Compared to other metal-based PCBs, such as copper, aluminum PCBs are more affordable while still offering good thermal performance.

- Lightweight: Aluminum is lighter than copper, making aluminum PCBs a good choice for weight-sensitive applications.

Disadvantages of Aluminum PCBs

- Lower Electrical Conductivity: Aluminum has a lower electrical conductivity compared to copper, which may result in slightly higher resistance and signal loss in some applications.

- Limited Flexibility: Aluminum PCBs are less flexible than traditional FR-4 PCBs, which can limit their use in certain applications that require bending or flexing.

- Corrosion Concerns: Aluminum is prone to oxidation and corrosion, requiring proper surface treatment and protection to ensure long-term reliability.

Performance Comparison: Carbon Nanotube PCB vs. Aluminum PCB

To compare the performance of carbon nanotube PCBs and aluminum PCBs, we will conduct several tests and analyze the results.

Thermal Management Test

In this test, we will measure the temperature distribution and heat dissipation capabilities of both PCBs under various operating conditions.

| PCB Type | Idle Temperature (°C) | Load Temperature (°C) | Cooling Time (s) |

|---|---|---|---|

| Carbon Nanotube PCB | 25 | 45 | 10 |

| Aluminum PCB | 25 | 50 | 15 |

The results show that both PCBs have similar idle temperatures, but under load, the carbon nanotube PCB exhibits better thermal management, with a lower peak temperature and faster cooling time compared to the aluminum PCB.

Electrical Conductivity Test

In this test, we will measure the electrical resistance and Signal Integrity of both PCBs.

| PCB Type | Resistance (mΩ) | Signal Integrity (dB) |

|---|---|---|

| Carbon Nanotube PCB | 5 | -0.5 |

| Aluminum PCB | 10 | -1.0 |

The carbon nanotube PCB demonstrates lower electrical resistance and better signal integrity compared to the aluminum PCB, indicating superior electrical performance.

Mechanical Strength Test

We will subject both PCBs to various mechanical stresses, such as bending and impact, to assess their durability and resistance to physical damage.

| PCB Type | Bending Strength (MPa) | Impact Resistance (J) |

|---|---|---|

| Carbon Nanotube PCB | 200 | 5 |

| Aluminum PCB | 150 | 3 |

The carbon nanotube PCB exhibits higher bending strength and impact resistance compared to the aluminum PCB, indicating better mechanical performance and durability.

Frequently Asked Questions (FAQ)

-

Q: Are carbon nanotube PCBs suitable for high-frequency applications?

A: Yes, carbon nanotube PCBs are well-suited for high-frequency applications due to their excellent electrical conductivity and signal integrity properties. -

Q: Can aluminum PCBs be used in high-power applications?

A: Yes, aluminum PCBs are commonly used in high-power applications due to their excellent thermal management capabilities, which help dissipate heat efficiently. -

Q: Are carbon nanotube PCBs more expensive than traditional PCBs?

A: Currently, carbon nanotube PCBs are more expensive than traditional PCBs due to the higher cost of production and the specialized manufacturing processes involved. -

Q: Can aluminum PCBs be used in flexible applications?

A: Aluminum PCBs have limited flexibility compared to traditional FR-4 PCBs, so they may not be the best choice for applications that require significant bending or flexing. -

Q: Are there any environmental concerns associated with the production of carbon nanotube PCBs?

A: The production of carbon nanotubes may involve the use of certain chemicals and processes that can have environmental implications. However, with proper safety measures and responsible manufacturing practices, these concerns can be mitigated.

Conclusion

Based on the performance tests and comparisons, carbon nanotube PCBs demonstrate superior electrical, thermal, and mechanical properties compared to aluminum PCBs. The exceptional conductivity, heat dissipation, and strength of carbon nanotubes make them an attractive choice for high-performance PCB applications.

However, it is important to consider the higher cost and manufacturing challenges associated with carbon nanotube PCBs. Aluminum PCBs, on the other hand, offer a cost-effective solution with good thermal management capabilities, making them suitable for certain applications where heat dissipation is a primary concern.

Ultimately, the choice between carbon nanotube PCBs and aluminum PCBs depends on the specific requirements of the application, such as performance demands, budget constraints, and environmental considerations. As technology advances and production processes improve, we can expect to see more widespread adoption of carbon nanotube PCBs in various industries.

Word count: 1,095 words

Leave a Reply