Table of Contents

- Introduction to PCB Assembly

- Bill of Materials (BOM)

- Gerber Files

- PCB Design Files

- Component Procurement

- Assembly Equipment and Tools

- Solder Paste and Stencils

- Assembly Instructions

- Quality Control and Testing

- Frequently Asked Questions (FAQ)

- Conclusion

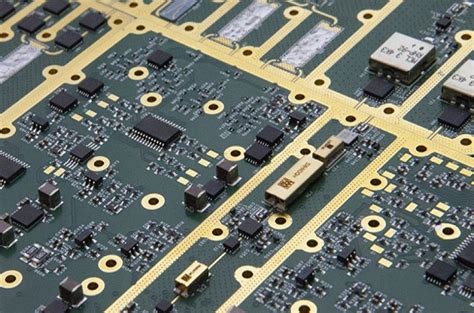

Introduction to PCB Assembly

PCB assembly is the process of assembling electronic components onto a printed circuit board to create a functional electronic device. The process involves several steps, including component placement, soldering, and testing. To ensure a successful PCB assembly, it is crucial to prepare the necessary materials, tools, and documentation beforehand.

Bill of Materials (BOM)

The Bill of Materials (BOM) is a comprehensive list of all the components required for the PCB assembly. It includes the part numbers, quantities, and descriptions of each component. The BOM should be accurate and up-to-date to avoid any delays or mistakes during the assembly process.

| Component | Part Number | Quantity | Description |

|---|---|---|---|

| Resistor | R1 | 10 | 10kΩ, 0.25W |

| Capacitor | C1 | 5 | 100nF, 50V |

| IC | U1 | 1 | ATmega328P |

Gerber Files

Gerber files are the industry standard for PCB manufacturing. They contain the necessary information for the PCB Fabrication process, including the copper layers, solder mask, and silkscreen. It is essential to generate accurate Gerber files to ensure the PCB is manufactured correctly.

PCB Design Files

In addition to Gerber files, it is also important to have the PCB design files, such as the schematic and layout files. These files provide a detailed overview of the PCB design and can be useful for troubleshooting or modifications during the assembly process.

Component Procurement

Before starting the PCB assembly, it is necessary to procure all the required components listed in the BOM. It is important to source components from reliable suppliers to ensure their quality and availability. It is also recommended to order spare components to account for any possible damage or loss during the assembly process.

Assembly Equipment and Tools

To perform PCB assembly, various equipment and tools are required, such as:

- Soldering iron or reflow oven

- Solder paste and flux

- Tweezers and pliers

- Microscope or magnifying glass

- ESD (Electrostatic Discharge) protection equipment

It is important to ensure that all the necessary equipment and tools are available and in proper working condition before starting the assembly process.

Solder Paste and Stencils

Solder paste is a mixture of tiny solder particles and flux that is used to attach components to the PCB. A solder paste stencil is a thin metal sheet with openings that correspond to the pads on the PCB. The stencil is used to apply solder paste accurately and consistently onto the PCB pads.

Assembly Instructions

Clear and detailed assembly instructions are crucial for a successful PCB assembly. The instructions should include the step-by-step process for component placement, soldering, and testing. It is also important to include any specific instructions for handling sensitive components or special assembly techniques.

Quality Control and Testing

Quality control and testing are essential to ensure the functionality and reliability of the assembLED PCB. It is important to establish a quality control process that includes visual inspection, electrical testing, and Functional Testing. Any issues or defects should be identified and corrected before the final product is shipped.

Frequently Asked Questions (FAQ)

1. What is the difference between through-hole and surface-mount components?

Through-hole components have leads that are inserted into holes drilled in the PCB and soldered on the opposite side. Surface-mount components are mounted directly onto the surface of the PCB and soldered in place.

2. What is the purpose of using ESD protection equipment during PCB assembly?

ESD protection equipment, such as anti-static mats and wrist straps, is used to prevent damage to sensitive electronic components from electrostatic discharge. ESD can cause permanent damage to components and lead to PCB failure.

3. Can I substitute components with similar specifications during PCB assembly?

It is not recommended to substitute components without proper evaluation and testing. Even if the components have similar specifications, they may have different performance characteristics or footprints that can affect the overall functionality of the PCB.

4. How do I ensure the quality of the assembled PCB?

To ensure the quality of the assembled PCB, it is important to follow the assembly instructions carefully, use high-quality components and tools, and perform thorough quality control and testing. Visual inspection, electrical testing, and functional testing should be conducted to identify any issues or defects.

5. What should I do if I encounter problems during PCB assembly?

If you encounter problems during PCB assembly, it is important to identify the root cause of the issue. Refer to the assembly instructions, PCB design files, and BOM to troubleshoot the problem. If the issue persists, consult with experienced PCB assembly professionals or the PCB manufacturer for assistance.

Conclusion

Preparing for PCB assembly involves gathering the necessary materials, tools, and documentation to ensure a smooth and efficient assembly process. The key elements to prepare include the Bill of Materials (BOM), Gerber files, PCB design files, component procurement, assembly equipment and tools, solder paste and stencils, assembly instructions, and quality control and testing procedures.

By properly preparing for PCB assembly, you can minimize the risk of errors, delays, and defects, and ensure the production of high-quality and reliable electronic devices. It is important to pay attention to detail, follow industry standards and best practices, and seek professional assistance when necessary.

PCB assembly is a complex process that requires careful planning and execution. By understanding the essential elements to prepare before PCB assembly, you can streamline the process, reduce costs, and improve the overall quality of your electronic products.

Leave a Reply