Flexible printed circuit boards (PCBs) are a type of circuit board that can bend and flex. OSH Park is a popular PCB manufacturer that offers high-quality flexible PCB fabrication services. This guide will provide an overview of OSH Park’s flexible PCB capabilities, the benefits of using flexible circuits, and key considerations when designing and ordering flexible PCBs from OSH Park.

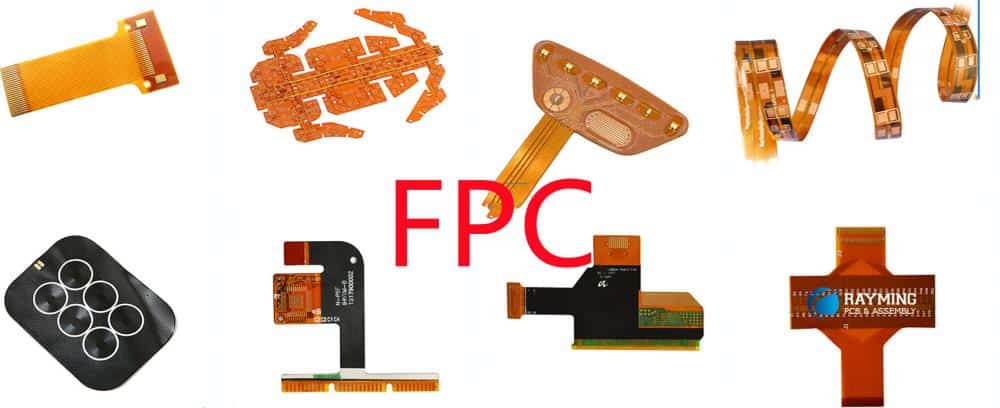

What are Flexible PCBs?

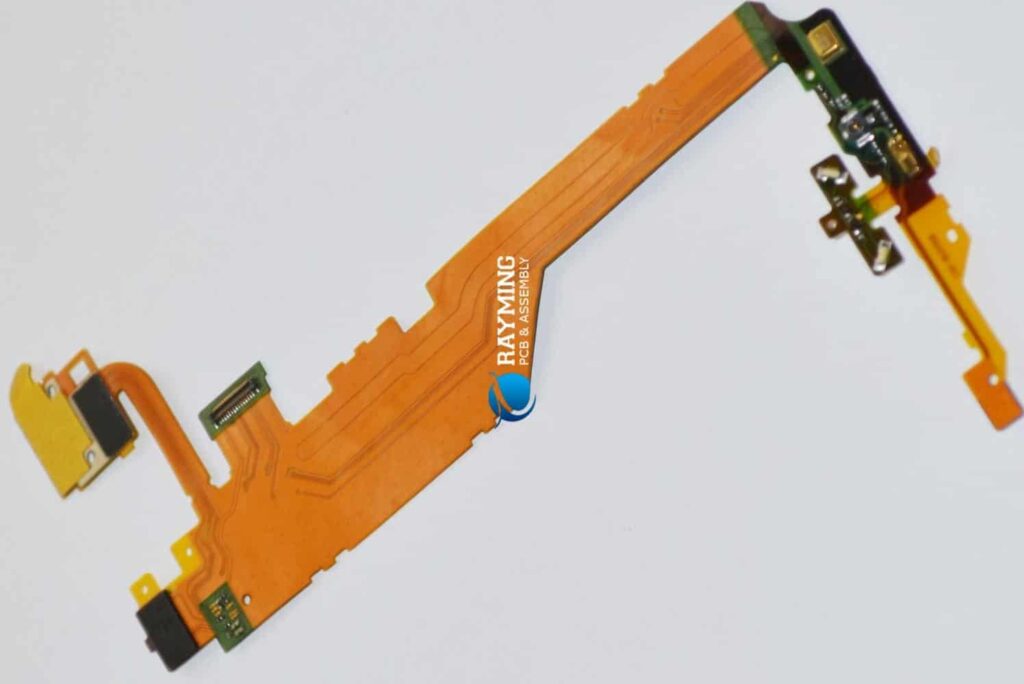

A flexible PCB is a printed circuit board constructed using flexible base materials like polyimide or polyester instead of traditional rigid FR-4 material. The conductive traces are bonded to the flexible substrate and can be bent and flexed repeatedly without cracking or peeling.

Flexible PCBs provide several advantages over rigid PCBs:

- Flexible – Can be bent, folded, twisted, and flexed to accommodate unique form factors and moving parts

- Durable – Withstand repeated bending and flexing without damage

- Lightweight – Lighter than rigid PCBs due to thin, flexible base material

- Thin – Extremely thin profile, some flexible PCBs are thinner than a strand of hair!

- Conformable – Can conform to irregular and dynamic surfaces

- Wearable – Ideal for wearable electronics because they conform to the body

- Space saving – Fold up into tight spaces where rigid PCBs won’t fit

Common applications for flexible PCBs include:

- Wearable devices

- Internet of Things (IoT) devices

- Medical devices

- Robotics and drones

- Automotive electronics

- Consumer electronics

- Defense electronics

Flexible PCB Materials

The most common base materials used in flexible PCB fabrication are:

| Material | Description |

|---|---|

| Polyimide (Kapton) | Excellent thermal stability and chemical resistance. Can withstand high temperatures. |

| Polyester (PET) | Low cost. Moderate thermal resistance and flexibility. |

| PEN | High heat resistance. Low moisture absorption. |

| Polyurethane | Very flexible and elastic. Can elongate substantially. |

The base material determines the key characteristics like flexural rigidity, flexibility, maximum bend radius, chemical resistance and operating temperature range.

OSH Park Flexible PCB Capabilities

OSH Park provides high-quality flexible PCB manufacturing services in the United States. Some key capabilities include:

Materials

- Polyimide flexible circuits down to 1 mil thickness

- Flexible solder mask and coverlay

Layer Count

- 1 to 4 layer flex PCBs

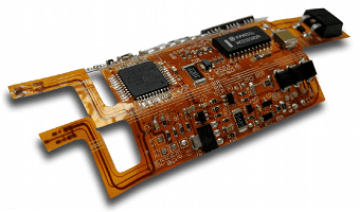

- Flex-rigid boards with combination of flex and rigid PCB sections

Trace/Space

- 6 mil minimum trace width

- 6 mil minimum spacing

Finishes

- Immersion silver (IAg)

- Immersion tin (ISn)

- Hard gold (ENIG)

- Electroless nickel immersion gold (ENIG)

Testing

- Netlist testing on all boards

- Flying probe electrical testing available

Design Rules

- Follows IPC 2221 standard

- Complete design rules available on OSH Park website

Turnaround Time

- Standard turnaround in ~15 days

- Expedited manufacturing available

Volume Pricing

- Cost-effective even at low volumes

- Volume discounts available for larger orders

OSH Park manufactures the flexible PCBs in panels consisting of multiple circuit boards. The finished boards are then separated prior to shipping.

Benefits of OSH Park Flex PCBs

Some of the key benefits of ordering flexible PCBs through OSH Park include:

Quality

- Consistently high-quality boards

- Rigorous testing and inspection at all process stages

Flexibility

- Polyimide material selection for excellent flex life

- Withstand repeated bending and flexing

Reliability

- Stringent quality control results in reliable boards

- Experienced team with expertise in flex PCB fabrication

Cost Effective

- Low minimum order quantities (start at 3 boards)

- Economical for prototyping and production

- Cost savings through panel utilization

Convenient File Upload

- User-friendly website makes ordering easy

- Upload Gerber files directly for manufacturing

Quick Turnaround

- Standard turnaround time in approximately 15 days

- Expedited manufacturing available for faster delivery

Customer Service

- Helpful sales engineers provide design feedback

- Support team available by phone and email

OSH Park reduces the barriers to using flexible PCBs by providing cost-effective and reliable flex board production. Even complex, multi-layer flex boards can be ordered in low volumes.

Design Considerations for Flexible PCBs

Designing a flexible PCB requires special considerations compared to rigid PCB design. Here are some key guidelines to follow:

Layer Stackup

Typical flex board layer stackups include:

- 1 Layer – single conductive layer with solder mask overlay.

- 2 Layers – conductive layers on both sides with flexible dielectric core in middle.

- Multilayer – multiple conductive layers separated by flexible dielectric.

Adhesives are used to bond the flexible dielectric layers together in multilayer designs.

Trace Width/Spacing

Use wider trace widths and spacings on flex PCBs compared to rigid boards due to increased risk of stress-related damage.

- Minimum trace width: 6 mil

- Minimum trace spacing: 6 mil

Bend Radius

Avoid tight/sharp bends to prevent trace cracking. The minimum bend radius should be at least 3-4 times the total board thickness for dynamic bending. For static bending, minimum bend radius can be slightly smaller.

Stiffeners

Consider adding stiffeners on sections of the PCB that do not require flexing. Stiffeners provide mechanical support and prevent unwanted bending.

Vias

Minimize use of large diameter vias which can act as weak points during flexing. Smaller microvias are preferred. Fill vias to strengthen plated barrel.

Pads

Use tear-drop shaped pads or rounded pad corners to reduce stress concentrations. Avoid rectangular pad shapes.

Flex Cuts

Flex cuts fully isolate sections of the PCB that need to flex completely. Use cross-hatched flex cuts rather than single cuts.

Component Placement

Place components in the rigid sections of flex-rigid boards. Avoid placing components in high flex zones.

Ordering from OSH Park

Ordering flexible PCBs from OSH Park is easy – just follow these steps:

- Sign Up – Create a free OSH Park account

- Upload Files – Upload your Gerber and drill files. OSH Park will check for errors.

- Customize Order – Select material, thickness, finishes, stencil, testing.

- Place Order – Enter shipping info and pay via credit card, PayPal or PO

- Manufacturing – OSH Park produces the boards in panels and separates them prior to shipping

- Shipping – Boards are shipped via USPS Priority or FedEx.

OSH Park provides free online design tools like their Gerber viewer and stackup tool. Their design guidelines contain detailed flex PCB design rules and recommendations.

Contact OSH Park sales or support at any point during the process for assistance with a flexible PCB order.

Flexible PCBs FAQ

Here are some frequently asked questions about flexible PCBs and ordering from OSH Park:

What are some typical applications for flexible PCBs?

Typical flexible PCB applications include wearable devices, medical devices, consumer electronics, automotive electronics, robotics, aerospace and defense, and IoT products. Their ability to bend and flex makes them well-suited for many applications where a rigid PCB would fail.

What design software can be used for flexible PCBs?

Any standard PCB design software like Altium, Cadence, Eagle, OrCAD, KiCad etc can be used. The PCB designer just needs to be aware of the specific design guidelines and fab requirements when laying out a flexible board.

What file formats does OSH Park accept?

OSH Park accepts the standard Gerber RS-274X and NC drill file formats. They recommend uploading both generated and native versions of your Gerber files.

How rigid do the rigid sections of a flex-rigid board need to be?

OSH Park recommends designing rigid sections to be similar to standard rigid PCBs. Use thicker copper (2 oz or greater) and avoid placing components near edges of rigid sections.

How long does it take to receive flex PCB prototypes from OSH Park?

OSH Park’s standard lead time is approximately 15 days. They offer expedited manufacturing in 5-7 days for an additional fee. Their online ordering system provides accurate delivery estimates.

Can I order flex PCB assembly or stencils from OSH Park?

OSH Park offers assembly and solder stencil ordering options to complement their PCB production capabilities. These services are provided through partner companies.

Conclusion

Flexible PCBs provide design flexibility and reliability for many applications where traditional rigid boards aren’t suitable. OSH Park enables designers to easily and affordably order high-quality flex circuit boards on demand. Their expert capabilities in flex PCB fabrication along with convenient online ordering system make OSH Park a top choice for sourcing flexible printed circuit boards in prototypes or production volumes.

Leave a Reply