Understanding the Basics of PCB and PCBA

When it comes to electronic devices, two terms that often come up are PCB and PCBA. While they may sound similar, they refer to different stages in the manufacturing process of electronic circuits. In this article, we’ll explore the differences between PCB and PCBA, their roles in electronics, and how they impact the overall functionality of devices.

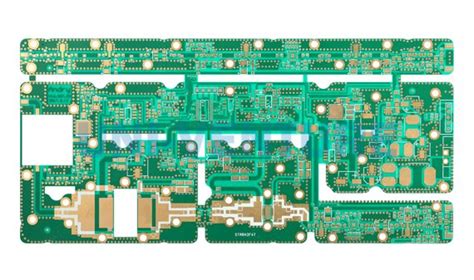

What is a PCB?

A PCB, or Printed Circuit Board, is the foundation of most electronic devices. It is a flat board made of insulating materials, such as fiberglass or composite epoxy, with conductive pathways etched or printed onto its surface. These pathways, known as traces, connect various electronic components and allow for the flow of electrical signals.

PCBs are designed using specialized software that creates a schematic diagram and a layout of the board. The schematic shows the electrical connections between components, while the layout determines the physical placement of those components on the board.

The Role of PCBs in Electronics

PCBs play a crucial role in the functionality and reliability of electronic devices. They provide a stable platform for components to be mounted on and ensure proper electrical connections between them. Some key advantages of using PCBs include:

- Miniaturization: PCBs allow for the compact arrangement of components, enabling the creation of smaller, more portable devices.

- Reliability: The fixed layout of PCBs reduces the risk of loose connections and short circuits, making devices more reliable.

- Mass production: PCBs can be easily replicated, allowing for the efficient mass production of electronic devices.

- Cost-effectiveness: The standardized manufacturing process of PCBs reduces production costs compared to other wiring methods.

Types of PCBs

There are several types of PCBs, each with its own characteristics and applications:

| PCB Type | Layers | Applications |

|---|---|---|

| Single-sided | 1 | Simple, low-cost devices |

| Double-sided | 2 | More complex devices, better space utilization |

| Multi-layered | 3+ | High-density, complex devices (e.g., smartphones, computers) |

| Flexible | Varies | Wearable devices, curved surfaces |

| Rigid-Flex | Varies | Combination of rigid and flexible sections for unique device shapes |

What is a PCBA?

A PCBA, or Printed Circuit Board Assembly, is the next step in the manufacturing process after the PCB has been fabricated. It involves the assembly of electronic components onto the PCB, creating a functional circuit.

The PCBA Process

The PCBA process typically involves several steps:

- Solder paste application: A thin layer of solder paste is applied to the PCB’s contact pads using a stencil or screen printing process.

- Component placement: Electronic components are placed onto the PCB using automated pick-and-place machines or manual placement for smaller batches.

- Reflow soldering: The PCB with components is heated in a reflow oven, melting the solder paste and creating electrical connections between the components and the board.

- Inspection and testing: The assembLED PCBA undergoes visual inspection and electrical testing to ensure proper functionality and adherence to quality standards.

The Importance of PCBA

PCBA is a critical stage in the manufacturing of electronic devices, as it brings together the PCB and its components to create a functional unit. A well-assembled PCBA ensures:

- Proper functionality: Accurate component placement and soldering ensure that the device functions as intended.

- Reliability: Thorough inspection and testing during the PCBA process help identify and rectify any issues, improving the overall reliability of the device.

- Efficiency: Automated PCBA processes allow for faster and more consistent assembly compared to manual methods.

PCB vs PCBA: Key Differences

While PCB and PCBA are closely related, they represent different stages in the manufacturing process and have distinct characteristics.

| Aspect | PCB | PCBA |

|---|---|---|

| Definition | Bare Board with etched conductive pathways | Assembled board with components mounted |

| Components | None | Electronic components soldered onto the board |

| Functionality | Provides a platform for electrical connections | A functional electronic circuit |

| Manufacturing Stage | Fabrication of the bare board | Assembly of components onto the PCB |

| Testing | Continuity and electrical tests on the bare board | Functional and quality tests on the assembled board |

| Cost | Lower cost compared to PCBA | Higher cost due to additional components and assembly |

Applications of PCBs and PCBAs

PCBs and PCBAs are used in a wide range of electronic devices across various industries:

Consumer Electronics

- Smartphones

- Laptops and computers

- Televisions

- Home appliances

Automotive Industry

- Engine control units (ECUs)

- Infotainment systems

- Advanced driver assistance systems (ADAS)

Medical Devices

- Diagnostic equipment

- Patient monitoring systems

- Implantable devices

Industrial Automation

- Process control systems

- Robotics

- Power electronics

Aerospace and Defense

- Avionics systems

- Satellite communication devices

- Military-grade equipment

Frequently Asked Questions (FAQ)

-

Q: Can a PCB function without being assembled into a PCBA?

A: No, a PCB alone cannot function as an electronic device. It requires the assembly of components onto the board to create a functional circuit. -

Q: Is it possible to repair or modify a PCBA?

A: Yes, PCBAs can be repaired or modified by skilled technicians. However, the complexity of the repair depends on the design of the PCBA and the nature of the issue. -

Q: What factors determine the cost of a PCB or PCBA?

A: The cost of a PCB or PCBA depends on various factors, such as the size of the board, the number of layers, the complexity of the design, the components used, and the manufacturing volume. -

Q: How do I choose between a PCB and a PCBA for my project?

A: The choice between a PCB and a PCBA depends on the stage of your project. If you are in the design phase, you’ll need a PCB. If you require a functional electronic circuit, you’ll need a PCBA. -

Q: What are the environmental considerations when manufacturing PCBs and PCBAs?

A: PCB and PCBA Manufacturing processes can involve hazardous chemicals and materials. Responsible manufacturers adhere to environmental regulations and implement eco-friendly practices, such as using lead-free solder and properly disposing of waste.

Conclusion

Understanding the differences between PCB and PCBA is crucial for anyone involved in the design, manufacturing, or procurement of electronic devices. While a PCB serves as the foundation for electrical connections, a PCBA brings together the components to create a functional circuit. By recognizing the roles and characteristics of each, you can make informed decisions when developing or sourcing electronic products.

As technology continues to advance, the importance of PCBs and PCBAs in our daily lives will only grow. From consumer electronics to industrial automation, these essential components form the backbone of the devices we rely on. By staying informed about PCB and PCBA technologies, you can navigate the ever-evolving landscape of electronics with confidence.

Leave a Reply