Introduction

Flexible printed circuit boards (PCBs) with LEDs are gaining popularity for their versatile applications in modern lighting solutions. Flexible LED PCBs provide several advantages over traditional rigid boards and enable innovative lighting designs not previously possible.

This article will provide an in-depth look at flexible LED PCB technology, their benefits, applications, and future outlook. We will also answer some frequently asked questions about these boards to help readers gain a comprehensive understanding of this emerging technology.

What are Flexible LED PCBs?

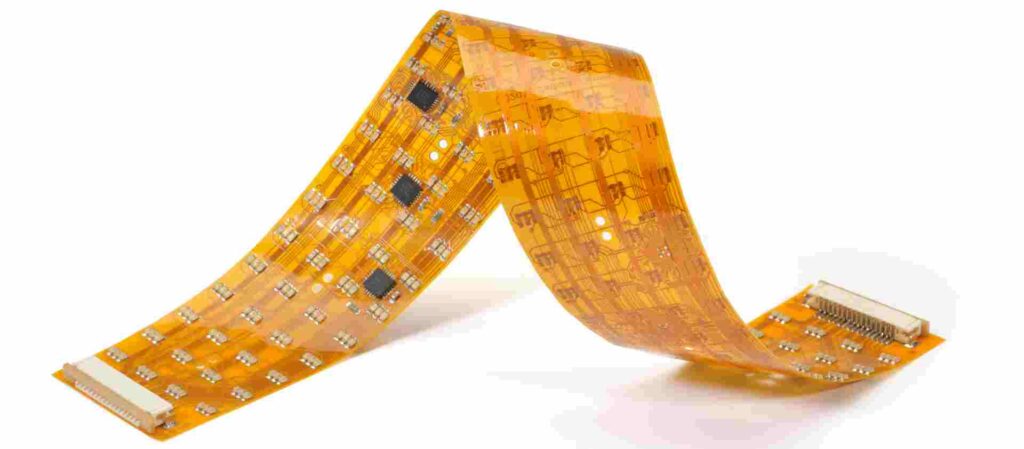

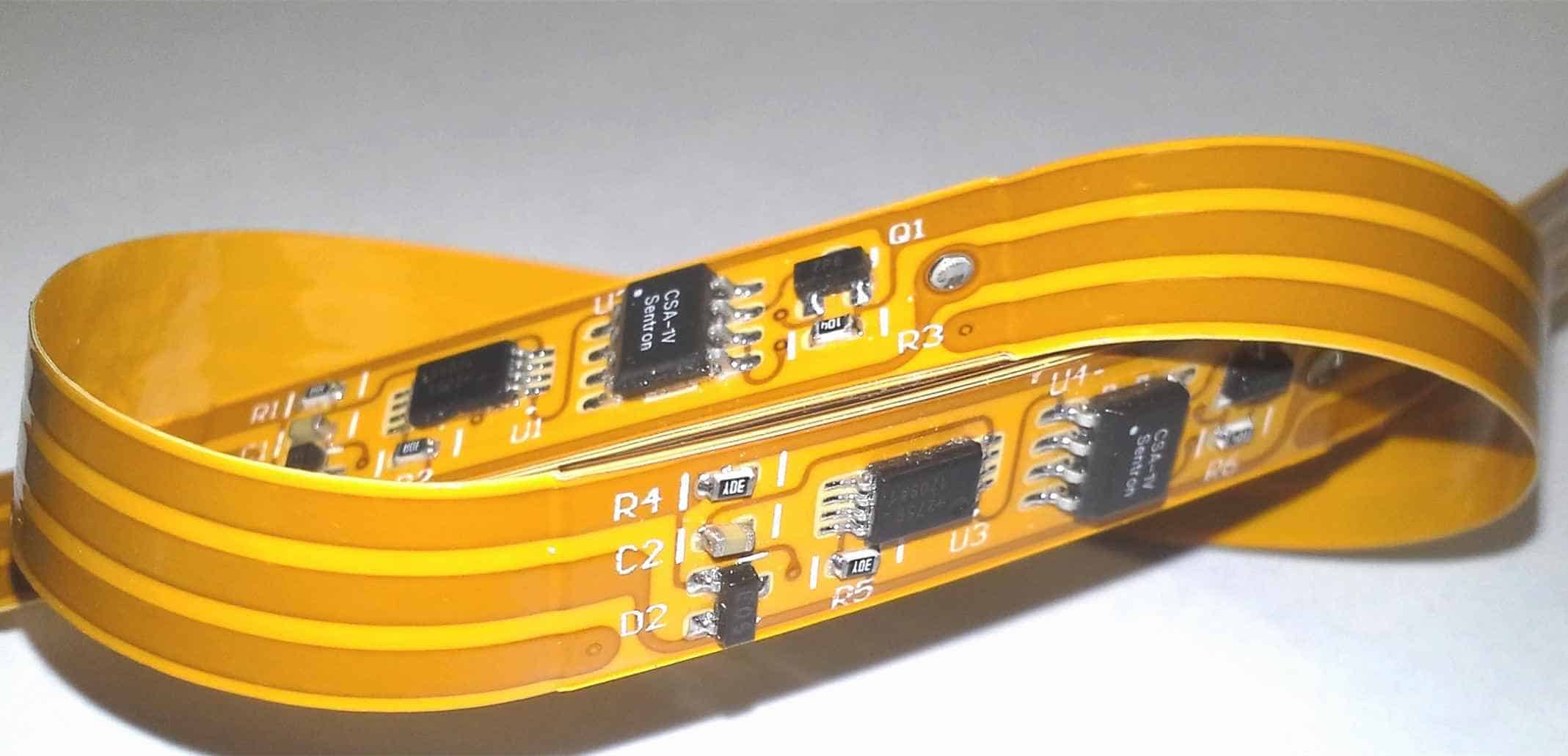

A flexible LED PCB utilizes a flexible base material like polyimide instead of the standard rigid fiberglass. Polyimide offers flexibility and heat resistance capabilities ideal for incorporating LEDs. Conductive materials are laminated onto the polyimide base to create the circuit traces interconnecting the LEDs.

The critical advantage flexible PCBs offer over rigid boards is their ability to bend and conform to any shape or surface. This adaptability opens up new possibilities for lighting design compared to standard rigid PCBs. Flexible LED boards with integrated driver electronics are thin, lightweight, and highly customizable.

Benefits of Flexible LED PCBs

Flexible LED PCBs provide several notable benefits that make them an attractive choice for lighting solutions:

Adaptability

The conformable nature of flexible PCBs allows them to mount onto curved surfaces and bend into any shape. This adaptability enables custom lighting designs for unconventional spaces and applications not possible earlier.

Thin and Lightweight Design

Flexible PCBs with LEDs can be extremely thin – less than 1 mm. This slim profile allows for discreet, unobtrusive integration into products and luminaires. Their lightweight nature also makes handling and installation easier.

Reliability

Polyimide material offers high heat and temperature resistance. This reliability allows flexible LED boards to endure hot operating conditions when multiple high-power LEDs are mounted onto them.

Easy Customization

Flexible PCBs allow creating custom layouts and patterns not feasible with rigid boards. Manufacturers can place LED components in any shape or configuration for innovative lighting effects.

Applications of Flexible LED PCBs

The combination of flexibility, thin profile, and customizability of flexible LED PCBs enable several unique application areas:

Wearable Lighting

Integrating flexible LED boards into fabrics or apparel allows creating illuminated wearable fashions and accessories. Lighted clothing items are an emerging consumer trend.

Backlighting

The slim profile and bendability of flexible LED boards make them ideal for display or signage backlighting. Curving the PCBs allows backlighting uneven surfaces.

Automotive Lighting

Flexible LED boards enable thin, conformal signal lights, brake lights, and interior lighting for automotive and transport applications.

Special Effects Lighting

With flexible PCBs, LEDs can mount onto props, sets, costumes and other irregular objects to create dynamic lighting effects for theatres, movies and events.

IoT Devices

Flexible LED boards can integrate into Internet of Things devices with unconventional form factors that require thin, bendable PCBs.

Medical Equipment

In medical devices with space constraints, flexible LED PCBs allow integrating indicator lights into the equipment’s tight confines.

| Application | Benefits |

|---|---|

| Wearable Lighting | Thin and flexible to integrate into fabrics |

| Backlighting | Conforms to curved surfaces for even backlighting |

| Automotive Lighting | Thin profile for discreet, conformal lighting |

| Special Effects Lighting | Can mount LEDs on irregular objects |

| IoT Devices | Adapts to unconventional device forms |

| Medical Equipment | Thin to fit into tight spaces |

This table summarizes some key applications for flexible LED PCBs and their benefits. The adaptability of these boards enables innovative lighting across several industries.

Future Outlook for Flexible LED PCBs

Several trends point towards a bright future for flexible LED PCB technology:

- Miniaturization – As LED components shrink in size, flexible PCBs will enable integrating even smaller LEDs for miniaturized lighting applications.

- Advances in Materials – New base materials like transparent polyimide films will enable translucent flexible PCBs for lighting+display applications.

- Growth in Wearables Market – With the booming wearables market, flexible LED PCBs will be key to creating illuminated clothing, fashion tech, and accessories.

- Customized Lighting – Flexible PCBs will allow further customization and personalization of lighting in automotive, displays, architectural lighting etc.

- Cost Improvements – Economies of scale and manufacturing improvements will reduce costs, making flexible LED PCBs more affordable.

In summary, the future looks promising for flexible LED PCB technology to enable innovation across a diverse range of lighting applications. Their versatility, customizability and improving economics will drive widespread adoption.

Frequently Asked Questions about Flexible LED PCBs

Here we answer some common queries about flexible LED PCB technology:

Q: How are flexible LED PCBs manufactured?

A: Manufacturing process involves laminating copper foil onto a thin polyimide base, etching the copper to form circuits and then mounting LED components. The boards can be single, double or multilayer flex circuits.

Q: Can components be mounted on both sides of flexible PCBs?

A: Yes, components can be assembled on single or both sides of the flexible PCB. Double sided mounting may require special termination methods.

Q: What densities of LEDs can flexible PCBs support?

A: With very thin base films, flexible boards can support moderately high densities. However, thermal management becomes critical for high-density LEDs.

Q: What is the typical thickness of flexible LED PCBs?

A: Flexible PCB thickness can range from 25 microns for ultra-thin types to over 250 microns for multilayer boards. Typical single layer boards are around 100 microns thick.

Q: Are flexible LED PCBs more expensive than rigid PCBs?

A: Generally flexible PCBs have a moderate cost premium over rigid boards. However, for custom small volume boards, flex PCBs can be economical.

Conclusion

Flexible LED printed circuit boards offer an innovative platform for modern, adaptable lighting solutions. Their thin, conformal and customizable nature allows addressing applications not possible earlier with rigid boards. Flexible LED PCBs will continue gaining prominence to meet industry demands for miniaturized, unconventional lighting designs. With technology improvements and cost reductions, flexible LED PCBs have a strong future outlook across a diverse range of lighting uses.

Leave a Reply