Introduction to Flex Circuits

Flexible printed circuit boards (flex circuits or flex PCBs) are a type of printed circuit board made using flexible substrate materials like polyimide or polyester. Unlike traditional rigid PCBs, flex circuits can bend and flex to fit into tight or moving spaces in electronic devices. They are commonly used when electronics need to mount on irregular or dynamic surfaces, in wearable devices, or in dynamic flexing applications like robotic arms or avionics. Flex circuits allow complex interconnectivity while conforming around joints or in three-dimensional configurations.

Flex PCBs offer many benefits compared to rigid boards:

- Greater flexibility and ability to conform to dynamic shapes

- Thinner, lightweight, and compact for smaller devices

- High connectivity density with fine traces and spacing

- Reduced wiring and simplified assembly

- Improved reliability with dynamic flexing motions

- Design innovation opportunities in 3D and wearable tech

However, flex circuit design comes with its own set of challenges and considerations for PCB designers and engineers:

Key Design Challenges for Flex PCBs

- Choosing optimal flexible materials

- Minimizing flex cracks with dynamic bending

- Maintaining trace integrity over flex zones

- Managing thermal stresses

- Handling high-density interconnects

- Addressing EMI shielding needs

- Withstanding environmental exposures

- Providing sufficient stiffness for assembly

This guide will provide a comprehensive overview of flex circuit design, materials, construction, modeling, analysis, and assembly considerations for developing robust flexible PCBs.

Flexible Substrate Materials

Choosing the right flexible material system is one of the most critical aspects in designing a successful flex circuit. The substrate material defines the flex circuit’s fundamental mechanical, electrical, and environmental capabilities. Key properties to evaluate when selecting materials include:

Flexibility

The flexural modulus determines the substrate’s inherent flexible properties. Lower modulus values indicate more flexible, easily bendable materials. Typical flex circuit materials have a flexural modulus between 0.3-10 GPa.

Dielectric Constant

The dielectric constant affects signal propagation speed, impedance, and crosstalk. Most flex circuit materials have a dielectric constant between 3-4.

Loss Tangent

The loss tangent indicates the dielectric loss and attenuation of high frequency signals. Lower loss tangent values minimize signal loss. Common values range from 0.002-0.025.

Thermal Properties

The thermal expansion coefficient affects reliability with temperature changes. The glass transition temperature indicates maximum application temperatures before mechanical changes occur.

Environmental Resistance

Important environmental factors to consider include moisture absorption, flammability, chemical resistance, and UV/weathering stability.

Thickness

Thinner materials allow tighter bend radii but impact stiffness and handling. Standard thicknesses range from 25-100 microns.

| Material | Flexural Modulus (GPa) | Dielectric Constant | Loss Tangent | Thickness (μm) |

|---|---|---|---|---|

| Polyimide | 2-5 | 3.2-3.5 | 0.002-0.010 | 25-100 |

| Polyester | 2-5 | 3.0-3.2 | 0.015-0.018 | 25-125 |

| LCP | 5-10 | 3.1-3.2 | 0.003-0.005 | 25-100 |

Polyimide films like Kapton HN are most commonly used due to their excellent flexibility, electrical performance, and thermal stability. However, polyester and liquid crystal polymer (LCP) films are also popular options. The substrate choice depends on balancing flexural, electrical, and reliability needs.

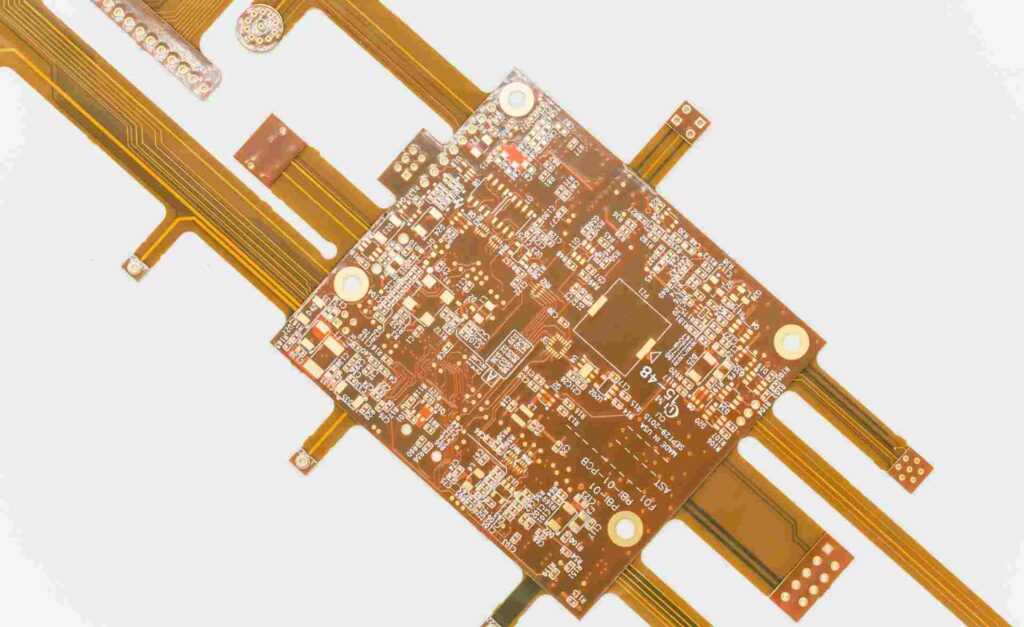

Flex Circuit Construction

Flex circuits consists of multiple layers of flexible substrate with conductive traces and features on one or both sides. Here are the basic construction elements:

Base Material

The flex circuit base is the core flexible dielectric film. Polyimide is most often used. Required thickness depends on manufacturing capabilities, stiffness needs, and flexibility requirements.

Conductive Traces

Usually copper traces are patterned on the polyimide base layer through additive, subtractive, or semi-additive metallization processes. Traces transmit signals and power.

Dielectric Coverlayer

A thin polyimide coverlayer is laminated over the copper to prevent shorts and environmental damage. Openings in the coverlayer provide testpoints and component access.

Stiffeners

To aid assembly and installation, additional polyimide or metal stiffeners are often added in select areas to provide strength and stability.

Adhesives

Acrylic or epoxy adhesives attach coverlayers, stiffeners, and components onto the flexible circuit layers.

Finishes and Coatings

Special finishes like ENIG, immersion silver, or solder mask are applied to protect and facilitate soldering.

With this basic construction, flex circuits can be designed with single or double-sided traces, multilayer circuits with complex interconnects, and mixed rigid-flex configurations.

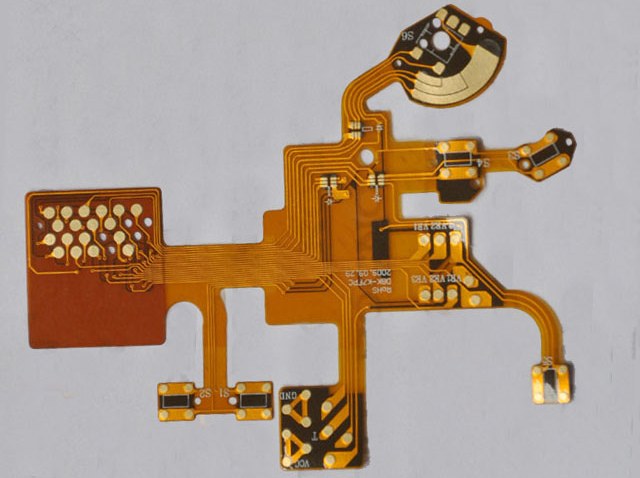

Flex Circuit Layout Considerations

Designing the physical layout and routing for a flex circuit requires special considerations across the flexible regions. Here are key guidelines for flex circuit layouts:

Bend Radii

A minimum bend radius must be maintained to avoid overstress and premature cracking. Typical flex materials allow bending to a minimum inside radius of 5-10 times the substrate thickness. For 50 micron polyimide, at least a 2.5mm radius would be recommended.

Flex Bend Areas

Conductive traces will fracture if flexed excessively so plan circuit routing to avoid traces crossing bending zones. Place flexible regions selectively between rigid areas.

Trace Width and Spacing

Use larger trace widths and spacing when crossing flexible areas to account for distortions. Aim for at least 150 micron lines/spaces.

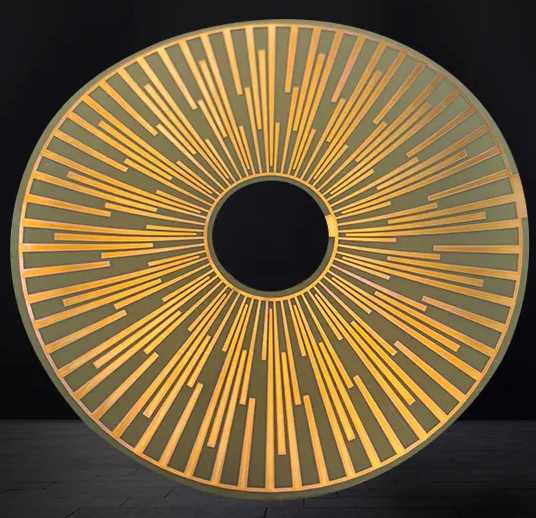

Trace Routing Angles

Avoid acute trace angles less than 30° across flex areas. Gradual curved traces withstand flexing much better than traces at sharp angles.

Annular Rings

Sufficient pad diameters and annular rings are essential for solder joint reliability. 50 mil pad diameters with 4-5 mil annular rings are typical.

Cross-hatching

Added cross-hatched copper balances stresses and prevents confirmation distortions over bending areas.

Stiffeners and Supports

Strategically placed stiffeners maintain stability for assembly and installation while allowing dynamic flexing only in designated zones.

Modeling and Analysis of Flex Circuits

Validating the reliability of flexible PCBs requires advanced modeling, simulation, and analysis with specialized tools. Important analyses to perform include:

Mechanical Stress Analysis

Finite element analysis predicts stresses and deformation over bending regions. This ensures trace integrity is maintained without overstressing materials.

Thermal Simulation

Thermal modeling analyzes temperature gradients and heat dissipation needs. This avoids flex circuit damage or failure from excessive heat during operation.

Vibration and Fatigue Analysis

Vibration analysis determines resonant modes and assesses fatigue life with repetitive dynamic bending stresses.

Drop Impact Testing

Simulating drop events validates robustness against sudden impacts during use.

Impedance Modeling

Transmission line modeling verifies matched impedance for high speed signals across flex regions.

With advanced simulations, engineers can optimize flex circuit constructions and trace routing to withstand mechanical, thermal, vibration, shock, and electrical stresses across real-world operating conditions.

Assembly and Manufacturing Processes

Specialized assembly and soldering processes are required to produce and populate flex circuits without damage.

Fabrication

Photolithographic processes precisely pattern copper traces and features onto flex substrates. Thin, lightweight materials are more challenging to handle than rigid boards during processing.

Layer Alignment

Maintaining layer-to-layer registration and trace alignment is critical, especially for multilayer flex circuits. Misalignments create defects.

Via Forming

Precisely formed microvias generate vertical interconnects between flex circuit layers. Reliable connections are essential.

Attachment

Parts are often assembled onto flex circuits through solder, conductive adhesive, or thermosonic bonding rather than insertion or press-fit.

Soldering

Reflow soldering operations require optimized temperature profiles, preheating, and cooling rates to avoid damage, warping, or delamination.

Rework

Repairs, modifications, and rework are challenging on fragile flex boards. Specially designed tweezer tools manipulate these boards without damage.

With rigorous process engineering controls, flex circuits can be fabricated and assembled to high yields and reliable quality standards.

Applications and Examples

Some examples of how flex circuits are transforming electronics:

Wearable Technology

In smartwatches and fitness bands, flex circuits conform comfortably to the wrist while allowing dynamic movements.

Mobile Devices

Phones and tablets use flex circuits for interconnectivity around hinged, folded, or sliding mechanisms.

Automotive Electronics

Flex circuits mount dashboard displays and enable steering wheel controls that can be positioned ergonomically.

Medical Devices

In hearing aids, prosthetics, and implants, flex circuits reliably fit into tiny spaces while enabling complex functionality.

Robotics and UAVs

Flexible circuits withstand millions of bending cycles in robotic arms. They also save weight and space in drone designs.

Consumer Electronics

Foldable laptops, flexible displays, and dynamic IoT products integrate flex circuits for innovation opportunities.

FAQ

What are the main benefits of using flex circuits?

The main benefits are increased flexibility and conformability, lighter weight and smaller size, simplified cabling and assembly, increased reliability in dynamic applications, and expanded design options for innovative form factors and movement.

How small can flex circuit traces and spaces be?

With advanced processes, trace widths and spaces approaching 50 microns are achievable. However, 150+ micron features are recommended for reliability across flex zones. Narrow 25 micron lines can be used in rigid regions.

Can components be mounted directly onto flex circuits?

Yes, components can be soldered or adhesively attached. However, the thin, lightweight nature of flex circuits means large or heavy components may require additional stiffeners, support structures, or specific mounting arrangements.

What limits the bend radius of a flex circuit?

The flex circuit’s minimum bend radius is limited by the substrate material’s flexural modulus, ductility, and thickness. Typical flex circuit materials allow a minimum inside bend radius of 5 to 10 times the substrate thickness before mechanical failure occurs.

How many flex cycles can a flex circuit withstand?

Properly designed flex circuits can achieve several million flex cycles before fatigue failure, but this depends significantly on the materials, trace routing, dynamic bending stresses, and other factors. Extensive modeling, testing, and qualification over expected conditions is required.

Summary

Flex circuits enable innovative electronics with their ability to dynamically flex and conform. However, realizing the benefits of flex PCBs requires advanced materials selection, layout strategies, modeling tools, assembly processes, and rigorous reliability testing. With sound engineering disciplines, flex circuits can withstand millions of flex cycles and empower the next generation of flexible, wearable, and compact electronics. This guide provides PCB designers and engineers an in-depth overview of best practices for developing robust flex circuits.

Leave a Reply