Introduction

Flex circuit boards, also known as flexible printed circuits (FPCs), are an essential component in modern electronics. As devices continue getting smaller and more compact, flex circuits allow for connections and circuitry in tight spaces where rigid boards just won’t fit. The flexible nature of these boards also allows for dynamic movement and bending in products where that is required.

With the growing reliance on flex circuits across many industries, there is increasing demand for reliable and high-quality flex circuit board manufacturing. This guide will provide a comprehensive overview of flex circuit board manufacturers, including key selection criteria, top manufacturers, and insights on the manufacturing process.

What Are Flex Circuit Boards?

To understand flex circuit board manufacturers, you first need to understand what flex circuits are and why they’re important.

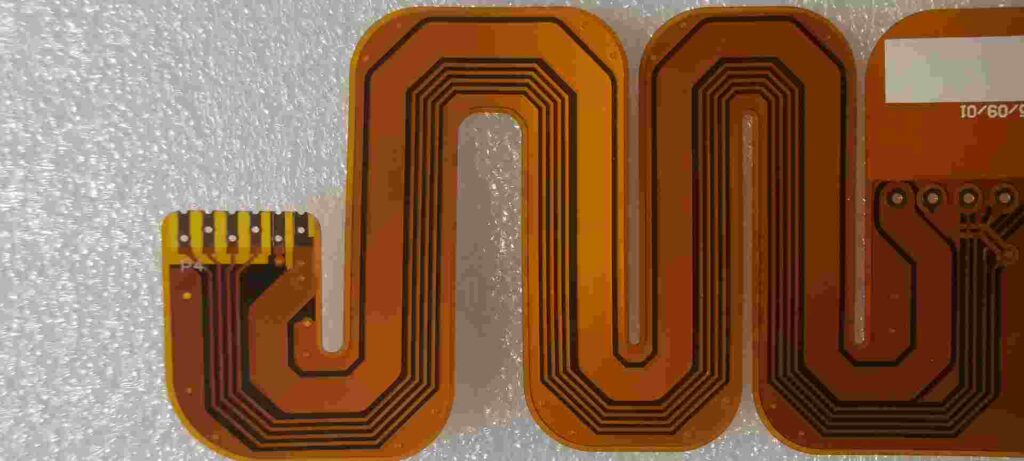

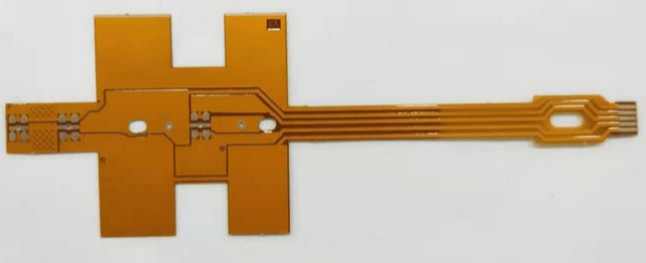

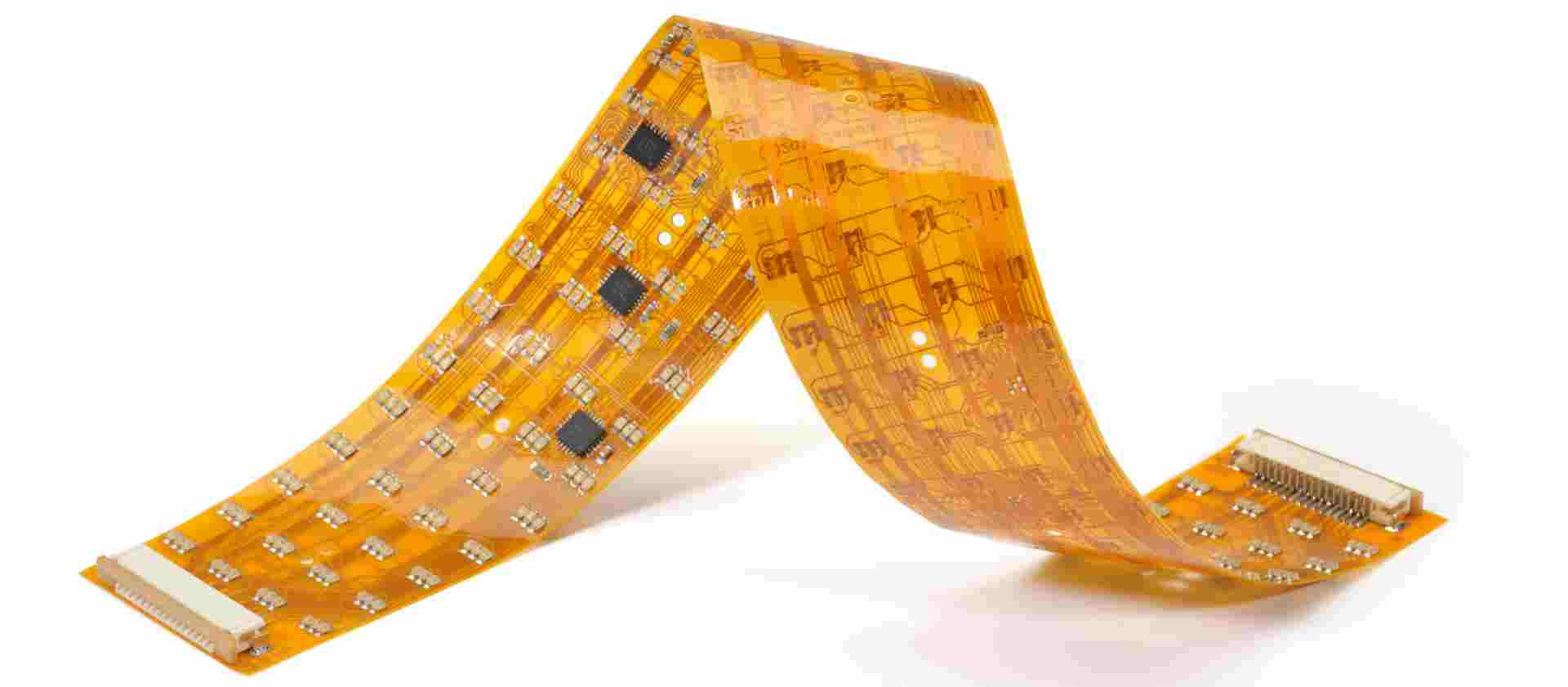

Flex circuits consist of thin, flexible dielectric substrates made from materials like polyimide. On top of the substrate, conductive tracks, pads, and other components are printed using copper foil and other conductive inks. The circuits can be single or double sided.

Key benefits of flex circuits:

- Extremely thin and lightweight – Allows for tight spaces and weight reduction

- Flexible and dynamic – Can bend, fold, twist, and flex repeatedly

- Durable and reliable – Withstands vibration, shock, and temperature changes

- Design freedom – Can take any shape needed for the application

- Efficient manufacturing – Allows high volume production

Flex circuits are widely used for interconnects in various electronics like mobile phones, laptops, cameras, automotive electronics, avionics, medical devices, IoT devices, and more. The global market for flex circuit boards is growing steadily.

Key Selection Criteria for Flex Circuit Board Manufacturers

Choosing the right flex circuit board manufacturer is crucial to get high quality boards delivered on time and on budget. Here are key factors to consider:

Experience and Specialization

Look for manufacturers who specialize in flex circuits and have many years of experience. They will have the expertise, capabilities, and resources tailored specifically to flex circuit fabrication.

Production Capabilities

Assess their production capabilities like minimum line width and spacing, layer stacking options, via formation, copper thickness, and other parameters. Ensure they can support the complexity and volumes needed.

Quality Systems

The manufacturer should follow strict quality control standards at every production stage. Confirm they are ISO certified and conduct rigorous testing and inspection.

Materials and Supply Chain

They should have relationships with top material suppliers and access to high quality substrate materials, copper foils, coverlays, etc. A robust supply chain reduces risk of shortages.

Design Support

Many manufacturers provide design support and DFM analysis to help optimize flex circuit designs for manufacturability. Look for these value-added services.

Customer Service

See how responsive and transparent they are with customers. Good communication is key throughout the development and production process.

Pricing

Get price quotations from multiple manufacturers to compare. Consider overall value, not just lowest cost. Avoid very cheap options which may have quality issues.

Top Flex Circuit Board Manufacturers

With thousands of manufacturers to choose from globally, it can be challenging picking out the leaders. Here are some of the top flex circuit board manufacturers:

Flexible Circuit Technologies (FCT)

FCT is a highly-rated manufacturer with over 50 years in flex and rigid-flex circuit boards. They have robust capabilities for complex, high-layer count boards. FCT provides extensive DFM support and is ITAR registered.

All Flex

All Flex is an award-winning manufacturer capable of extremely fine line precision down to 0.0008 inch traces. They are a vertically integrated company with design, fabrication, and assembly for fast turnarounds.

Flexible Interconnect Technology (FIT)

FIT utilizes advanced manufacturing technology for high-mix, low-to-medium volume flex boards. They are ISO 13485 certified for medical devices and ITAR registered. Rapid prototyping services available.

Dymax

Dymax manufactures flex circuits with excellent dimensional stability and consistency with high layer counts. They specialize in very fast delivery of prototype through production quantities.

American Standard Circuits

This leading manufacturer provides cost-effective flex and rigid-flex circuits in 3 to 10 day lead times. Their “Flexperts” program connects customers to flex circuit design assistance.

Compass Circuits

Compass Circuits fabricates flex, rigid-flex, and multilayer boards for defense, aerospace, and other specialized industries. They are certified to MIL-PRF-31032 and ITAR registered.

This covers some of the top manufacturers, but there are many others to evaluate based on your specific needs. Reaching out for quotes and assessing their capabilities is recommended.

Flex Circuit Board Manufacturing Process

Now that we’ve covered the basics of flex circuit boards and top manufacturers, let’s take a quick look at the manufacturing process. How exactly are these boards fabricated? Here is a high-level overview:

1. Design and Layout

Like PCBs, the process starts with circuit design and board layout in EDA software. The Gerber files are then generated.

2. Photoimageable Processing

The base substrate material is coated with photoresist and imaged to create the circuit pattern.

3. Copper Etching

The exposed copper is etched away to leave only the desired conductive pattern on the substrate.

4. Cleaning and Coating

The boards are cleaned and coated with protective coverlay and other coatings. Additional laminations can be done.

5. Via Formation

For multilayer boards, vias are formed to interconnect outer and inner layers.

6. Testing and Inspection

Each board goes through electrical testing, AOI inspection, and other quality checks.

7. Singulation

The large panel is diced into individual boards by depaneling.

8. Shipping

Finally, the finished flex boards are shipped to the customer’s facility.

Advanced manufacturers will utilize automated processes like direct imaging (LDI) to achieve fine features and consistency. The best leverage smart factory technology with data analytics and IoT.

Flex Circuit Board Manufacturing: Frequently Asked Questions

Here are some common questions related to flex circuit board manufacturing:

What are the minimum dimensions achievable?

The best flex circuit manufacturers can produce extremely fine traces and spaces down to 25 microns or below. The thinnest flex substrates are 12.5 to 25 microns thick.

How long does manufacturing take?

Lead times range from 24 hours for prototyping services to 4-6 weeks for higher complexity designs. Multi-layer flex boards take longer than single/double layer.

How should I prepare design files?

Use manufacturer DFM guidelines and work with engineers early in the design stage. Provide Gerber and drill files optimized for the process.

Can flex boards be assembled?

Yes, SMT assembly can be done directly on the flex board or on a rigid section. Automated optical inspection ensures quality.

Does flex circuit production require dedicated tools?

Specialized tools are required like laser direct imaging. But high-volume manufacturers will already have this capital equipment developed for flex fabrication.

Conclusion

Flex circuit boards enable electronics miniaturization and innovation across many industries. Selecting the right flex circuit manufacturer requires evaluating experience, capabilities, quality systems, materials, and costs. Leading manufacturers like Flexible Circuit Technologies, All Flex, and others provide the expertise and processes to deliver high-performing flex circuits reliably and at scale. With demand growing, manufacturers continue to expand capacity and capabilities.

Leave a Reply