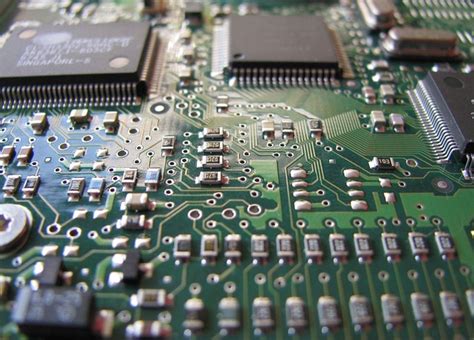

What is Fine Pitch PCBA?

Fine pitch PCBA refers to the assembly of electronic components on a PCB with a pitch (the distance between the centers of adjacent leads or pads) of less than 0.5mm. This advanced manufacturing technique allows for the placement of components with extremely small lead spacing, enabling the creation of highly compact and dense PCBs.

Advantages of Fine Pitch PCBA

- Miniaturization: Fine pitch PCBA enables the assembly of smaller components, resulting in reduced PCB sizes and more compact electronic devices.

- Increased Functionality: With the ability to accommodate more components on a single PCB, fine pitch PCBA allows for enhanced functionality and complex circuitry in a limited space.

- Improved Performance: The close proximity of components in fine pitch PCBA reduces signal paths, leading to improved electrical performance and reduced signal interference.

- Cost-effectiveness: By maximizing the utilization of PCB real estate, fine pitch PCBA reduces material costs and increases production efficiency.

0.05mm Finest Pitch PCBA Solution

While fine pitch PCBA generally refers to component spacing of less than 0.5mm, the 0.05mm finest pitch PCBA solution represents the cutting edge of this technology. This advanced assembly technique enables the placement of components with a pitch as small as 0.05mm, pushing the boundaries of PCB miniaturization.

Challenges in 0.05mm Finest Pitch PCBA

Achieving successful 0.05mm finest pitch PCBA comes with its own set of challenges:

- Precision Placement: The extremely small pitch requires highly accurate and precise placement of components, necessitating advanced pick-and-place machines with exceptional accuracy and repeatability.

- Soldering Techniques: Traditional Soldering Methods may not be suitable for 0.05mm pitch components. Advanced soldering techniques, such as laser soldering or jet printing, are often employed to ensure reliable connections.

- Inspection and Quality Control: Inspecting and verifying the integrity of 0.05mm pitch connections requires high-resolution imaging systems and sophisticated quality control processes.

- Design Considerations: PCB design for 0.05mm finest pitch PCBA demands meticulous attention to detail, including optimized pad sizes, Solder mask openings, and trace routing to ensure manufacturability and reliability.

Overcoming the Challenges

To overcome the challenges associated with 0.05mm finest pitch PCBA, manufacturers employ a combination of advanced technologies and expertise:

- High-Precision Equipment: Investing in state-of-the-art pick-and-place machines, inspection systems, and soldering equipment ensures the necessary accuracy and precision for 0.05mm pitch assembly.

- Skilled Workforce: Assembling 0.05mm pitch components requires highly skilled and experienced technicians who are well-versed in the intricacies of fine pitch PCBA.

- Rigorous Process Control: Implementing strict process controls, including environmental monitoring, material handling, and quality assurance procedures, helps maintain consistency and reliability in 0.05mm pitch assembly.

- Collaboration with Designers: Close collaboration between PCB designers and assembly experts ensures that the PCB layout is optimized for 0.05mm pitch assembly, considering factors such as pad sizes, solder mask openings, and component placement.

Applications of 0.05mm Finest Pitch PCBA

The 0.05mm finest pitch PCBA solution finds applications in various industries and products that demand extreme miniaturization and high performance:

- Wearable Electronics: Smartwatches, fitness trackers, and other wearable devices benefit from the compact size and enhanced functionality enabled by 0.05mm pitch assembly.

- Medical Devices: Implantable medical devices, such as pacemakers and neural stimulators, require highly miniaturized and reliable PCBAs, making 0.05mm pitch assembly an ideal solution.

- Aerospace and Defense: Aerospace and defense applications often require compact, high-performance electronics that can withstand harsh environments, and 0.05mm pitch assembly helps meet these demands.

- Telecommunications: The miniaturization of telecommunications equipment, such as smartphones and network devices, relies on fine pitch PCBA to accommodate the increasing number of components and functions in a limited space.

Future of Fine Pitch PCBA

As technology continues to advance and the demand for smaller, more powerful electronic devices grows, the future of fine pitch PCBA looks promising. Researchers and manufacturers are continuously pushing the boundaries of PCB Assembly, exploring new materials, processes, and technologies to enable even finer pitch assembly.

Some of the emerging trends in fine pitch PCBA include:

- 3D Packaging: 3D packaging technologies, such as through-silicon vias (TSVs) and package-on-package (PoP), enable vertical stacking of components, further increasing the density and miniaturization of PCBAs.

- Embedded Components: Embedding active and passive components within the PCB Substrate itself reduces the need for surface-mounted components, allowing for even greater miniaturization and improved performance.

- Advanced Materials: The development of advanced PCB materials, such as high-density interconnect (HDI) substrates and low-loss dielectrics, supports the realization of finer pitch assembly and high-speed signal transmission.

- Automation and AI: The integration of automation and artificial intelligence (AI) in the PCBA process helps improve accuracy, repeatability, and efficiency, enabling manufacturers to tackle the challenges of fine pitch assembly more effectively.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between fine pitch PCBA and standard PCBA?

A: Fine pitch PCBA refers to the assembly of components with a pitch of less than 0.5mm, while standard PCBA typically involves components with a pitch of 0.5mm or greater. Fine pitch PCBA enables greater miniaturization and higher component density compared to standard PCBA. -

Q: What are the main challenges in achieving 0.05mm finest pitch PCBA?

A: The main challenges in achieving 0.05mm finest pitch PCBA include precision placement of components, suitable soldering techniques, accurate inspection and quality control, and optimized PCB design. Overcoming these challenges requires advanced equipment, skilled personnel, rigorous process control, and close collaboration between designers and assembly experts. -

Q: What industries benefit the most from 0.05mm finest pitch PCBA?

A: Industries that benefit the most from 0.05mm finest pitch PCBA include wearable electronics, medical devices, aerospace and defense, and telecommunications. These industries require highly miniaturized, high-performance electronics that can be achieved through fine pitch assembly. -

Q: How does 0.05mm finest pitch PCBA compare to other fine pitch assembly techniques?

A: The 0.05mm finest pitch PCBA represents the cutting edge of fine pitch assembly technology. It enables the placement of components with an extremely small pitch of 0.05mm, surpassing the capabilities of other fine pitch assembly techniques that typically have a minimum pitch of 0.3mm to 0.4mm. -

Q: What advancements can we expect in fine pitch PCBA in the future?

A: The future of fine pitch PCBA is expected to bring advancements such as 3D packaging, embedded components, advanced PCB materials, and the integration of automation and AI in the assembly process. These developments will further push the boundaries of PCB miniaturization, performance, and manufacturing efficiency.

Conclusion

Fine pitch PCBA, particularly the 0.05mm finest pitch PCBA solution, represents a significant milestone in the advancement of electronics manufacturing. By enabling the assembly of extremely small components with a pitch of just 0.05mm, this technology opens up new possibilities for miniaturization, enhanced functionality, and improved performance in a wide range of electronic devices.

While achieving successful 0.05mm finest pitch PCBA comes with its own set of challenges, manufacturers are leveraging advanced equipment, skilled personnel, rigorous process control, and close collaboration with designers to overcome these obstacles. As technology continues to evolve, we can expect further advancements in fine pitch PCBA, pushing the boundaries of what is possible in the world of electronics manufacturing.

As the demand for smaller, more powerful, and highly efficient electronic devices continues to grow, fine pitch PCBA, especially the 0.05mm finest pitch PCBA solution, will play a crucial role in shaping the future of the electronics industry. By embracing this technology and its potential, manufacturers can stay ahead of the curve and deliver cutting-edge products that meet the ever-increasing expectations of consumers and businesses alike.

| Pitch Range | Classification | Advantages | Challenges |

|---|---|---|---|

| ≥ 0.5mm | Standard PCBA | Widely available, cost-effective | Limited miniaturization |

| 0.3mm – 0.4mm | Fine Pitch PCBA | Increased miniaturization and functionality | Requires advanced equipment and processes |

| 0.05mm | Finest Pitch PCBA | Extreme miniaturization, enhanced performance | Precision placement, soldering, inspection, and design challenges |

Leave a Reply