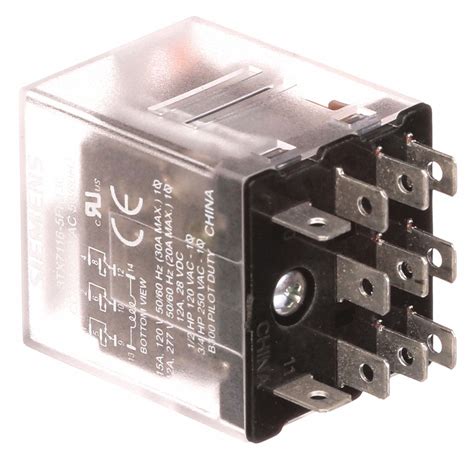

What is a DPDT Relay?

A Double Pole Double Throw (DPDT) relay is an electromechanical switch that uses an electromagnet to control two separate electrical circuits simultaneously. It has two sets of contacts, each with a normally open (NO) and normally closed (NC) position, allowing for greater flexibility in switching configurations compared to simpler relay types like SPST or SPDT Relays.

Key Features of DPDT Relays

- Two independent switching circuits

- Normally open and normally closed contacts for each circuit

- Electrically operated using an electromagnet

- Can handle higher current and voltage loads than solid-state relays

- Provides electrical isolation between control and switched circuits

How Does a DPDT Relay Work?

A DPDT relay consists of an electromagnet, an armature, and two sets of electrical contacts. When the relay coil is energized by applying the appropriate voltage, it creates a magnetic field that attracts the armature. The armature, in turn, moves the contact arms, switching the state of the contacts from their default position (NC) to the energized position (NO).

DPDT Relay Operation

- In the de-energized state, the NC contacts are connected to the common terminal, while the NO contacts remain open.

- When the coil is energized, the armature moves, causing the contact arms to switch positions.

- The NO contacts now connect to the common terminal, while the NC contacts open.

- When the coil is de-energized, the armature returns to its original position, and the contacts revert to their default state.

DPDT Relay Schematic and Symbol

The schematic symbol for a DPDT relay consists of two sets of contacts, each with a common (COM), normally open (NO), and normally closed (NC) terminal. The coil is represented by a separate symbol, often with polarity markings to indicate the positive and negative terminals.

Types of DPDT Relays

DPDT relays come in various types, each designed for specific applications and environments. Some common types include:

- General-purpose DPDT relays

- Miniature DPDT relays

- Power DPDT relays

- Latching DPDT relays

- Reed DPDT relays

- Solid-state DPDT relays

Comparison of DPDT Relay Types

| Relay Type | Typical Current Rating | Typical Voltage Rating | Key Features |

|---|---|---|---|

| General-purpose | 10-30A | 120-240VAC, 24-48VDC | Versatile, wide range of applications |

| Miniature | 1-5A | 12-24VDC | Small size, low power consumption |

| Power | 30-100A | 240-480VAC, 48-120VDC | High current handling, robust construction |

| Latching | 5-10A | 12-24VDC | Maintains state without continuous power |

| Reed | 0.5-2A | 5-24VDC | Fast switching, long life, low power |

| Solid-state | 1-10A | 3-240VDC | No moving parts, silent operation, fast switching |

Applications of DPDT Relays

DPDT relays find use in a wide range of applications across various industries, such as:

- Industrial control systems

- Automotive electronics

- Home automation

- HVAC systems

- Security systems

- Telecommunications

- Medical equipment

Examples of DPDT Relay Applications

Industrial Control Systems

In industrial settings, DPDT relays control machinery, motors, and other high-power devices. They provide electrical isolation between the control circuitry and the high-voltage, high-current loads, ensuring safety and reliability.

Automotive Electronics

DPDT relays are used in various automotive applications, such as controlling headlights, fog lights, horns, and other electrical accessories. They allow for the switching of high-current loads using low-current control signals from the vehicle’s electronic control units (ECUs).

Home Automation

In home automation systems, DPDT relays control lighting, HVAC, and other appliances. They enable the centralized control of multiple devices using a single control signal, simplifying the overall system design and operation.

Selecting the Right DPDT Relay

When choosing a DPDT relay for a specific application, consider the following factors:

- Coil voltage and current

- Contact rating (current and voltage)

- Switching speed

- Mechanical life expectancy

- Operating temperature range

- Mounting type (PCB, socket, panel)

- Size and weight

- Cost

DPDT Relay Selection Guide

| Parameter | Consideration |

|---|---|

| Coil voltage and current | Must match the control circuit’s specifications |

| Contact rating | Must exceed the maximum load current and voltage |

| Switching speed | Faster relays for time-critical applications |

| Mechanical life expectancy | Higher for applications with frequent switching |

| Operating temperature range | Must cover the expected environmental conditions |

| Mounting type | Depends on the available space and installation requirements |

| Size and weight | Smaller and lighter for space-constrained applications |

| Cost | Balance performance and reliability with budget constraints |

Installing and Wiring DPDT Relays

Proper installation and wiring are crucial for the safe and reliable operation of DPDT relays. Follow these general guidelines:

- Ensure the relay is rated for the intended application

- Use the correct wire gauge for the expected current

- Provide adequate insulation and strain relief

- Protect the relay contacts from inductive loads using suppression devices (e.g., diodes, varistors)

- Follow the manufacturer’s instructions for mounting and wiring

- Adhere to relevant electrical codes and safety standards

DPDT Relay Wiring Diagram

A typical DPDT relay wiring diagram includes the coil connections and the contact connections for both switching circuits. The coil is connected to the control circuit, while the contacts are connected to the load circuits.

Troubleshooting DPDT Relays

If a DPDT relay is not functioning as expected, follow these troubleshooting steps:

- Check the coil voltage and polarity

- Verify the contact connections and continuity

- Inspect the relay for signs of physical damage or wear

- Test the relay operation using a multimeter or relay tester

- Replace the relay if it is found to be defective

Common DPDT Relay Problems and Solutions

| Problem | Possible Causes | Solutions |

|---|---|---|

| Relay does not energize | Incorrect coil voltage, open coil, faulty control circuit | Check coil voltage and continuity, repair control circuit |

| Contacts do not switch | Damaged contacts, foreign material, insufficient coil voltage | Clean or replace contacts, check coil voltage |

| Intermittent operation | Loose connections, damaged contacts, electrical noise | Tighten connections, replace relay, add suppression devices |

| Overheating | Excessive load current, insufficient ventilation | Verify load current, provide adequate cooling |

DPDT Relay Maintenance and Best Practices

To ensure the long-term reliability and performance of DPDT relays, follow these maintenance and best practices:

- Regularly inspect relays for signs of wear or damage

- Clean relay contacts periodically to prevent buildup of contaminants

- Ensure proper ventilation to prevent overheating

- Use relays within their specified ratings and operating conditions

- Implement surge protection and contact suppression where necessary

- Keep spare relays on hand for quick replacement in case of failure

Frequently Asked Questions (FAQ)

- What is the difference between a DPDT and an SPDT relay?

-

A DPDT relay has two sets of contacts, each with a common, normally open, and normally closed terminal, allowing for the control of two separate circuits. An SPDT relay has only one set of contacts, limiting it to controlling a single circuit.

-

Can a DPDT relay be used as an SPDT relay?

-

Yes, a DPDT relay can be used as an SPDT relay by simply using only one set of contacts and leaving the other set unconnected.

-

What is the purpose of the normally closed (NC) contacts in a DPDT relay?

-

The normally closed contacts provide a connection when the relay is de-energized, which can be used to implement fail-safe functionality or to control a secondary circuit that should be active when the primary circuit is off.

-

How do I protect a DPDT relay from voltage spikes caused by inductive loads?

-

To protect a DPDT relay from voltage spikes, use suppression devices such as diodes, varistors, or RC snubbers connected across the relay contacts or the inductive load.

-

Can solid-state DPDT relays be used interchangeably with electromechanical DPDT relays?

- While solid-state DPDT relays can be used in many of the same applications as electromechanical DPDT relays, they have different characteristics, such as faster switching speeds, silent operation, and no moving parts. However, they may be more sensitive to voltage transients and have lower current handling capabilities. It is essential to carefully consider the specific requirements of the application when deciding between solid-state and electromechanical relays.

Conclusion

DPDT relays are versatile and reliable switching devices used in a wide range of applications, from industrial control systems to home automation. By understanding their working principles, selection criteria, installation, and maintenance best practices, users can effectively integrate DPDT relays into their designs and ensure optimal performance and longevity. When selecting a DPDT relay, consider factors such as coil voltage, contact rating, switching speed, and environmental conditions. Proper installation, wiring, and protection against inductive loads are crucial for safe and reliable operation. Regular maintenance, including inspection and cleaning, can help prevent failures and extend the relay’s lifespan. By following the guidelines and best practices outlined in this comprehensive guide, users can confidently incorporate DPDT relays into their projects and systems.

Leave a Reply