What is an SPDT Relay?

An SPDT (Single Pole Double Throw) relay is an electromechanical switch that uses an electromagnet to control the switching of electrical contacts. It has one common terminal and two switchable terminals, allowing it to switch a circuit between two different paths. When the relay coil is energized by applying voltage, the armature is attracted to the electromagnet, causing the common terminal to switch from one contact to the other.

Key Features of SPDT Relays

- Single pole: It has one common terminal.

- Double throw: It can switch between two different paths.

- Electromagnetically operated: The switching action is controlled by an electromagnet.

- Galvanic isolation: The control circuit (coil) is electrically isolated from the switched circuit (contacts).

- Versatile: SPDT relays can handle a wide range of voltages and currents.

How Does an SPDT Relay Work?

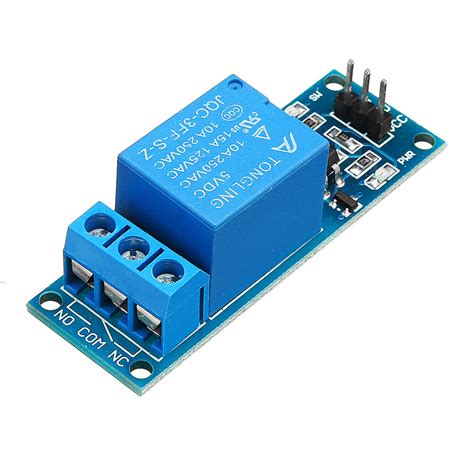

Basic Components of an SPDT Relay

- Coil: The electromagnet that controls the switching action.

- Armature: A movable magnetic component that is attracted to the electromagnet when the coil is energized.

- Contacts: The electrical terminals that are switched by the movement of the armature.

- Common (COM): The terminal that is always connected to the circuit.

- Normally Closed (NC): The terminal that is connected to the common when the coil is not energized.

- Normally Open (NO): The terminal that is connected to the common when the coil is energized.

Principle of Operation

- When no voltage is applied to the coil, the armature is in its resting position, and the common terminal is connected to the NC contact.

- When voltage is applied to the coil, it creates a magnetic field that attracts the armature.

- The armature moves, causing the common terminal to disconnect from the NC contact and connect to the NO contact.

- When the voltage is removed from the coil, the magnetic field collapses, and the armature returns to its resting position, reconnecting the common terminal to the NC contact.

Schematic Symbol and Wiring

The schematic symbol for an SPDT relay is shown below:

NO

|

COM -----+-----

|

NC

|

|

Coil

To wire an SPDT relay, follow these steps:

- Connect the load to the common terminal.

- Connect one end of the circuit to the NC terminal for the default state (when the coil is not energized).

- Connect the other end of the circuit to the NO terminal for the switched state (when the coil is energized).

- Apply the appropriate voltage to the coil terminals to control the switching action.

Types of SPDT Relays

Electromechanical SPDT Relays

Electromechanical SPDT relays use a physical armature and contacts to switch the circuit. They are further classified based on their construction and operating characteristics:

- General-purpose relays: Suitable for most applications with moderate switching capacity.

- Power relays: Designed to handle higher voltages and currents.

- Reed relays: Use reed switches instead of mechanical contacts, offering faster switching and longer life.

- Latching relays: Maintain their state even when the coil is not energized, requiring a separate pulse to change the state.

Solid-State SPDT Relays

Solid-state SPDT relays use semiconductor devices, such as transistors or thyristors, to perform the switching action. They offer several advantages over electromechanical relays:

- Faster switching speeds

- No moving parts, resulting in longer life and higher reliability

- Silent operation

- Immunity to vibration and shock

- Smaller size and lighter weight

However, solid-state relays have some limitations, such as:

- Lower switching capacity compared to electromechanical relays

- Sensitivity to temperature and voltage transients

- Higher cost

Applications of SPDT Relays

SPDT relays find applications in various fields, including:

- Industrial automation and control systems

- Automotive electronics (e.g., lighting, HVAC, power windows)

- Home automation and smart devices

- Telecommunications and networking equipment

- Medical devices and instrumentation

- Energy management and power distribution systems

- Security and access control systems

- Test and measurement equipment

Example Application: Motor Control

One common application of SPDT relays is in motor control circuits. Consider a scenario where an SPDT relay is used to control the direction of a DC motor:

NO

|

COM ----+----

|

NC

|

|

Coil

|

|

/ \

/ \

/ \

/ \

/ \

/ \

/ \

/ \

/ \

/ \

/ \

/ \

+ -

\ /

\ /

\ /

\ /

\ /

\ /

\ /

\ /

\ /

\ /

\ /

\ /

|

|

M

In this example:

- When the coil is not energized, the common terminal is connected to the NC contact, and the motor rotates in one direction.

- When the coil is energized, the common terminal switches to the NO contact, reversing the polarity of the voltage applied to the motor, causing it to rotate in the opposite direction.

This simple setup demonstrates how an SPDT relay can be used to control the direction of a motor by switching the polarity of the applied voltage.

Choosing the Right SPDT Relay

When selecting an SPDT relay for a specific application, consider the following factors:

- Coil voltage and current: Ensure that the relay coil is compatible with the control circuit’s voltage and can be adequately driven by the available current.

- Contact rating: Choose a relay with contacts rated for the voltage and current of the switched circuit, with an appropriate safety margin.

- Switching speed: Consider the required switching speed and choose a relay that meets or exceeds the application’s requirements.

- Mechanical durability: For applications with frequent switching, select a relay with a high mechanical life rating.

- Environmental factors: Consider the operating temperature, humidity, and other environmental conditions, and choose a relay that can withstand these factors.

- Size and mounting: Ensure that the relay’s dimensions and mounting options are compatible with the available space and mounting requirements.

Relay Specifications and Datasheets

When evaluating relays, refer to their datasheets for detailed specifications and performance characteristics. Key specifications to look for include:

- Coil voltage and current

- Contact rating (voltage and current)

- Switching capacity (in VA or watts)

- Switching speed (operate and release times)

- Mechanical and electrical life

- Operating temperature range

- Dimensions and mounting options

By carefully reviewing the relay specifications and selecting a relay that meets the application’s requirements, you can ensure reliable and efficient operation of the switched circuit.

Relay Protection and Best Practices

To ensure the longevity and reliable operation of SPDT relays, consider the following protection measures and best practices:

- Coil suppression: Use a suppression diode or varistor across the coil terminals to protect the relay and control circuit from voltage spikes during switching.

- Contact protection: For inductive loads, such as motors or solenoids, use a snubber circuit (RC or diode) across the contacts to suppress arcing and extend contact life.

- Proper sizing: Select a relay with a contact rating and switching capacity appropriate for the load to prevent overheating and premature failure.

- Mechanical protection: In vibration-prone environments, use relays with reinforced mounting or shock absorbers to prevent mechanical damage.

- Regular maintenance: Periodically inspect the relay for signs of wear, corrosion, or damage, and replace it if necessary.

- Proper wiring: Ensure that the relay is wired correctly, with the appropriate gauge wire and secure connections, to prevent electrical faults and overheating.

By following these best practices and protection measures, you can maximize the performance and lifespan of SPDT relays in your applications.

Troubleshooting SPDT Relay Issues

If an SPDT relay is not functioning as expected, follow these troubleshooting steps:

- Check the coil voltage and polarity: Ensure that the correct voltage is applied to the coil terminals and that the polarity is correct.

- Verify the coil continuity: Use a multimeter to check the continuity of the coil. If the coil is open or has a higher than expected resistance, the relay may need to be replaced.

- Inspect the contacts: Check for signs of wear, corrosion, or damage on the contacts. Clean or replace the relay if necessary.

- Test the switched circuit: Verify that the load is properly connected to the common and NO/NC terminals and that the circuit is complete.

- Check for external factors: Look for any external factors that may be affecting the relay’s operation, such as excessive vibration, temperature extremes, or electrical interference.

By systematically troubleshooting the relay and its associated circuits, you can identify and resolve issues, ensuring the proper operation of the SPDT relay in your application.

Frequently Asked Questions

-

Q: Can an SPDT relay be used for AC and DC loads?

A: Yes, SPDT relays can be used for both AC and DC loads, provided that the relay’s contact rating is appropriate for the voltage and current of the load. -

Q: What is the difference between an SPDT relay and an SPST relay?

A: An SPDT (Single Pole Double Throw) relay has one common terminal and two switchable contacts (NO and NC), while an SPST (Single Pole Single Throw) relay has one common terminal and only one switchable contact (either NO or NC). -

Q: How do I determine the coil voltage of an SPDT relay?

A: The coil voltage of an SPDT relay is typically specified in the relay’s datasheet or on the relay itself. It is important to ensure that the control circuit’s voltage matches the specified coil voltage to ensure proper operation. -

Q: Can I use an SPDT relay for high-frequency switching applications?

A: The suitability of an SPDT relay for high-frequency switching depends on the relay’s specifications, particularly the switching speed and contact bounce time. For high-frequency applications, consider using solid-state relays or specialized high-frequency relays. -

Q: How do I protect an SPDT relay from voltage spikes and surges?

A: To protect an SPDT relay from voltage spikes and surges, use a suppression diode or varistor across the coil terminals. This will help absorb the energy from voltage spikes and protect the relay and control circuit from damage.

Conclusion

SPDT relays are versatile and widely used electromechanical switches that play a crucial role in many electrical and electronic applications. By understanding their working principle, types, and applications, you can effectively incorporate SPDT relays into your designs and troubleshoot any issues that may arise.

When selecting an SPDT relay, consider factors such as coil voltage, contact rating, switching speed, and environmental conditions. Always refer to the relay’s datasheet for detailed specifications and follow best practices for relay protection and wiring.

By properly applying and maintaining SPDT relays, you can ensure reliable and efficient switching in your applications, from industrial automation and motor control to home automation and telecommunications.

Leave a Reply