Introduction to BOM Components Purchase

When it comes to manufacturing electronic products, the FlexPCB.org/?p=1919″>Bill of Materials (BOM) is a critical document that lists all the components required to build the product. Purchasing these components is a crucial step in the manufacturing process, and it can be a complex and time-consuming task. In this comprehensive guide, we’ll explore the key aspects of BOM components purchase, including sourcing, pricing, quality control, and inventory management.

Understanding the BOM

What is a BOM?

A Bill of Materials (BOM) is a comprehensive list of all the components, parts, and materials needed to manufacture a product. It includes details such as part numbers, quantities, descriptions, and sometimes even supplier information. The BOM serves as a blueprint for the purchasing team to acquire the necessary components for production.

Types of BOMs

There are several types of BOMs, each serving a specific purpose:

- Engineering BOM (EBOM): Created by the engineering team, the EBOM lists all the components and parts required to design and prototype the product.

- Manufacturing BOM (MBOM): Derived from the EBOM, the MBOM includes additional information necessary for the manufacturing process, such as assembly instructions and packaging requirements.

- Configurable BOM (CBOM): Used for products with multiple variations or customizable options, the CBOM allows for the creation of different product configurations based on customer requirements.

BOM Hierarchy

A BOM is typically structured in a hierarchical manner, with the finished product at the top and the individual components and subassemblies listed below. This hierarchy helps in understanding the relationships between components and aids in inventory management.

| Level | Description |

|---|---|

| 0 | Finished Product |

| 1 | Main Assemblies |

| 2 | Subassemblies |

| 3 | Individual Components |

Sourcing BOM Components

Identifying Suppliers

One of the first steps in BOM components purchase is identifying potential suppliers. Consider the following factors when selecting suppliers:

- Reputation and reliability

- Product quality and consistency

- Pricing and payment terms

- Lead times and delivery performance

- Minimum order quantities (MOQs)

- Technical support and communication

Supplier Evaluation and Selection

Once you have identified potential suppliers, it’s essential to evaluate and select the most suitable ones based on your specific requirements. This process may involve:

- Requesting quotes and comparing pricing

- Reviewing supplier certifications and quality control processes

- Conducting supplier audits or site visits

- Negotiating terms and conditions

- Establishing long-term Partnerships

Managing Supplier Relationships

Building and maintaining strong relationships with suppliers is crucial for ensuring a smooth and efficient BOM components purchase process. Regular communication, performance monitoring, and continuous improvement initiatives can help foster positive supplier relationships.

Pricing and Cost Analysis

Cost Drivers

Several factors influence the cost of BOM components, including:

- Raw material prices

- Manufacturing processes

- Order quantities

- Shipping and logistics costs

- Currency fluctuations

Price Negotiation Strategies

To optimize costs, consider the following strategies when negotiating prices with suppliers:

- Leverage volume discounts

- Explore alternative components or suppliers

- Implement long-term contracts

- Utilize competitive bidding

- Establish cost-sharing agreements for non-recurring expenses (NREs)

Total Cost of Ownership (TCO)

When evaluating the cost of BOM components, it’s important to consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also factors such as:

- Inventory carrying costs

- Quality assurance and inspection costs

- Transportation and logistics expenses

- Warranty and return costs

Quality Control and Assurance

Defining Quality Requirements

Clearly define the quality requirements for BOM components, including:

- Functional specifications

- Material and performance standards

- Tolerance and dimensions

- Certification requirements (e.g., RoHS, UL)

Incoming Inspection and Testing

Implement a robust incoming inspection and testing process to ensure the quality of received components. This may include:

- Visual inspection for damage or defects

- Functional Testing

- Sample testing for critical components

- Certificates of Conformance (CoCs) review

Supplier Quality Management

Work closely with suppliers to maintain and improve the quality of BOM components by:

- Conducting regular supplier audits

- Implementing corrective and preventive action (CAPA) processes

- Sharing quality metrics and feedback

- Collaborating on continuous improvement initiatives

Inventory Management

Inventory Control Strategies

Effective inventory management is crucial for optimizing BOM components purchase. Consider the following strategies:

- Economic Order Quantity (EOQ): Determine the optimal order quantity that minimizes inventory holding costs and ordering costs.

- Just-in-Time (JIT) Inventory: Coordinate with suppliers to receive components just before they are needed in production, reducing inventory carrying costs.

- Safety Stock: Maintain a buffer inventory to mitigate the risk of stockouts due to demand fluctuations or supply chain disruptions.

- ABC Analysis: Prioritize inventory management efforts based on the value and criticality of components.

Inventory Tracking and Visibility

Implement an inventory management system that provides real-time visibility into stock levels, usage rates, and reorder points. This may involve using tools such as:

- Enterprise Resource Planning (ERP) systems

- Warehouse Management Systems (WMS)

- Barcode or RFID tracking

- Automated inventory alerts and notifications

Obsolescence Management

Proactively manage component obsolescence to avoid supply chain disruptions and ensure the long-term availability of BOM components. This may involve:

- Monitoring component life cycles and end-of-life (EOL) notifications

- Identifying and qualifying alternative components

- Collaborating with suppliers on last-time buys or long-term supply agreements

- Redesigning products to accommodate component changes

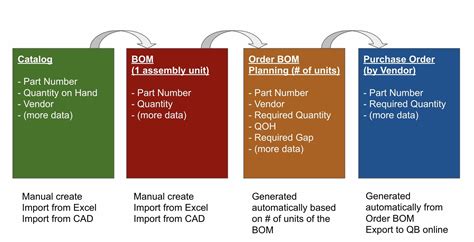

BOM Components Purchase Process

Request for Quote (RFQ)

Initiate the BOM components purchase process by sending a Request for Quote (RFQ) to potential suppliers. The RFQ should include:

- Detailed component specifications

- Required quantities and delivery dates

- Quality and certification requirements

- Pricing and payment terms

Purchase Order (PO) Placement

Once a supplier has been selected, place a Purchase Order (PO) that includes:

- PO number and date

- Supplier information

- Component details and quantities

- Pricing and payment terms

- Delivery instructions and Incoterms

Order Tracking and Expediting

Regularly track the status of BOM components orders and proactively address any delays or issues. This may involve:

- Communicating with suppliers for order updates

- Expediting critical orders

- Monitoring shipping and logistics progress

- Updating stakeholders on order status

Receipt and Invoice Processing

Upon receipt of BOM components, verify the quantity and quality of the shipment and process the supplier invoice. This may include:

- Matching the PO, receipt, and invoice

- Resolving any discrepancies

- Processing payment according to agreed terms

- Updating inventory records

Continuous Improvement

Performance Metrics and KPIs

Establish key performance indicators (KPIs) to measure and monitor the effectiveness of your BOM components purchase process. Common metrics include:

- On-time delivery (OTD)

- Defect parts per million (DPPM)

- Inventory turnover ratio

- Cost savings or avoidance

- Supplier lead time

Process Optimization

Continuously review and optimize your BOM components purchase process to improve efficiency, reduce costs, and mitigate risks. This may involve:

- Streamlining workflows and approvals

- Automating manual tasks

- Implementing digital tools and platforms

- Conducting regular process audits and reviews

Best Practices and Lessons Learned

Document and share best practices and lessons learned from your BOM components purchase experience. This knowledge sharing can help drive continuous improvement across the organization and foster a culture of excellence.

Conclusion

Purchasing BOM components is a critical aspect of electronics manufacturing that requires careful planning, execution, and continuous improvement. By understanding the key elements of the BOM components purchase process, from sourcing and pricing to quality control and inventory management, you can ensure a smooth and efficient supply chain that supports your product development and production goals.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between an Engineering BOM (EBOM) and a Manufacturing BOM (MBOM)?

A: An EBOM is created by the engineering team and lists all the components and parts required to design and prototype the product. An MBOM, on the other hand, is derived from the EBOM and includes additional information necessary for the manufacturing process, such as assembly instructions and packaging requirements. -

Q: How do I select the right suppliers for my BOM components?

A: When selecting suppliers, consider factors such as their reputation and reliability, product quality and consistency, pricing and payment terms, lead times and delivery performance, minimum order quantities (MOQs), and technical support and communication. Conduct a thorough evaluation and select suppliers that best meet your specific requirements. -

Q: What is the Total Cost of Ownership (TCO) in the context of BOM components purchase?

A: The Total Cost of Ownership (TCO) includes not only the purchase price of BOM components but also factors such as inventory carrying costs, quality assurance and inspection costs, transportation and logistics expenses, and warranty and return costs. Considering the TCO helps in making informed decisions and optimizing overall costs. -

Q: How can I ensure the quality of BOM components?

A: To ensure the quality of BOM components, clearly define quality requirements, implement a robust incoming inspection and testing process, and work closely with suppliers on quality management. This may involve conducting supplier audits, implementing corrective and preventive action (CAPA) processes, sharing quality metrics and feedback, and collaborating on continuous improvement initiatives. -

Q: What are some strategies for managing component obsolescence?

A: Strategies for managing component obsolescence include monitoring component life cycles and end-of-life (EOL) notifications, identifying and qualifying alternative components, collaborating with suppliers on last-time buys or long-term supply agreements, and redesigning products to accommodate component changes. Proactive obsolescence management helps avoid supply chain disruptions and ensures the long-term availability of BOM components.

Leave a Reply