ALL ABOUT FLEX PCB

-

PCB Solver – Outline/Milling Editor

Posted by

–

Read more: PCB Solver – Outline/Milling Editor

Read more: PCB Solver – Outline/Milling EditorIntroduction to PCB Solver PCB Solver is a powerful and user-friendly software tool designed to streamline the process of creating and editing printed circuit board (PCB) outlines and milling paths. Whether you are a professional PCB designer or a hobbyist, PCB Solver offers a comprehensive set of features to help […]

-

What is an open on a PCB?

Posted by

–

Read more: What is an open on a PCB?

Read more: What is an open on a PCB?Understanding PCB Opens A PCB open occurs when there is an unintended break in the conductive pathway, preventing electrical current from flowing as intended. This can happen in various parts of the PCB, such as: Traces: The thin copper lines that connect components on the PCB Vias: The small holes […]

-

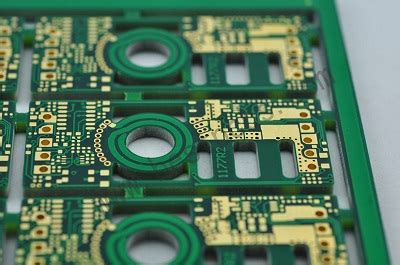

ENEPIG vs ENIG: Which Surface Finish is Better?

Posted by

–

Read more: ENEPIG vs ENIG: Which Surface Finish is Better?

Read more: ENEPIG vs ENIG: Which Surface Finish is Better?What is ENEPIG? ENEPIG is a surface finish that consists of three layers: electroless nickel, electroless palladium, and immersion gold. The process involves depositing a layer of electroless nickel onto the copper pads of the PCB, followed by a thin layer of electroless palladium, and finally, a layer of immersion […]

-

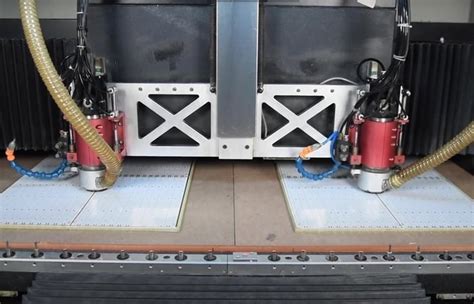

Profiling -V-cut Scoring

Posted by

–

Read more: Profiling -V-cut Scoring

Read more: Profiling -V-cut ScoringWhat is Profiling V-cut? Profiling V-cut, also known as V-grooving or V-scoring, is a technique used in the packaging and printing industry to create precise, clean folds in various materials, such as paper, cardboard, or plastic. This method involves cutting a V-shaped groove into the material, which allows for easier […]

-

What is the galvanic process of electrolysis?

Posted by

–

Read more: What is the galvanic process of electrolysis?

Read more: What is the galvanic process of electrolysis?Table of Contents History and Discovery Principles of Galvanic electrolysis Electrochemical Cells Redox Reactions Factors Affecting Galvanic Electrolysis Applications of Galvanic Electrolysis Metal Refining Electroplating Production of Chemicals Other Applications Advantages and Disadvantages Future Developments FAQ Conclusion References Request Flex PCB Manufacturing & Assembly Quote Now History and Discovery The […]

-

Bare Board Testing

Posted by

–

Read more: Bare Board Testing

Read more: Bare Board TestingWhat is a Bare Board? A bare board, also known as a printed circuit board (PCB) without components, is the foundation of any electronic device. It consists of a non-conductive substrate, typically made of fiberglass or other composite materials, with conductive copper traces etched onto its surface. These traces form […]

-

New timeline makes order tracking smarter

Posted by

–

Read more: New timeline makes order tracking smarter

Read more: New timeline makes order tracking smarterWhat is an Order-Tracking Timeline? An order-tracking timeline is a visual representation of an order’s journey from placement to delivery. It displays key milestones chronologically, giving customers a clear overview of their order status. By presenting information in an intuitive timeline format, retailers can improve transparency, reduce customer inquiries, and […]

-

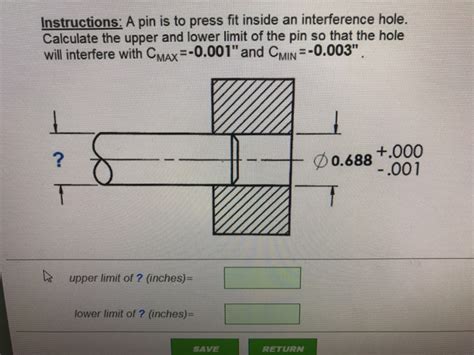

What are Press-Fit Holes?

Posted by

–

Read more: What are Press-Fit Holes?

Read more: What are Press-Fit Holes?Introduction to Press-Fit Holes Press-fit holes, also known as interference fit holes, are a type of mechanical fastening method used to join two components together without the need for additional fasteners such as screws, bolts, or adhesives. This technique relies on the principle of elastic deformation, where the hole diameter […]

-

What paste to be used on heat sink?

Posted by

–

Read more: What paste to be used on heat sink?

Read more: What paste to be used on heat sink?Introduction to Heatsink paste Heatsink paste, also known as thermal paste, thermal grease, or thermal compound, is a crucial component in ensuring efficient heat transfer between a heat-generating device (such as a CPU or GPU) and a heatsink. The primary purpose of heatsink paste is to fill the microscopic air […]

-

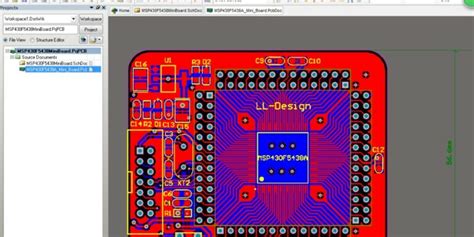

KiCAD – Rayming reads in native KiCAD-data

Posted by

–

Read more: KiCAD – Rayming reads in native KiCAD-data

Read more: KiCAD – Rayming reads in native KiCAD-dataIntroduction to KiCAD and Rayming KiCAD is an open-source electronic design automation (EDA) software that allows users to design printed circuit boards (PCBs) from schematic capture to PCB layout. It has gained popularity among hobbyists, students, and professionals due to its free availability and robust features. Rayming is a company […]