ALL ABOUT FLEX PCB

-

PCB Basics knowledge

Posted by

–

Read more: PCB Basics knowledge

Read more: PCB Basics knowledgeIntroduction to PCB Basics Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in almost every electronic device, from smartphones and computers to industrial equipment and medical devices. PCBs provide a platform for electronic components to be mounted and connected, allowing for the creation of complex […]

-

Read more: An Introduction to High Density Interconnect PCBs

Read more: An Introduction to High Density Interconnect PCBsHow are HDI PCBs Manufactured? The HDI PCB manufacturing process involves building up the interconnect structure layer by layer on the surface of the board. This is known as sequential lamination or a built-up process. The typical steps are: Starting with a core PCB panel Drilling any through-holes Imaging and […]

-

What is SMT Tombstoning

Posted by

–

Read more: What is SMT Tombstoning

Read more: What is SMT TombstoningTable of Contents Introduction to SMT Tombstoning Causes of SMT Tombstoning Preventing SMT Tombstoning Troubleshooting and Solving SMT Tombstoning Frequently Asked Questions (FAQ) Conclusion Request Flex PCB Manufacturing & Assembly Quote Now Introduction to SMT Tombstoning What is Surface Mount Technology (SMT)? Surface Mount Technology (SMT) is a method of […]

-

Read more: How Often Can You Raise a PCB to Lead-free Soldering Temperatures?

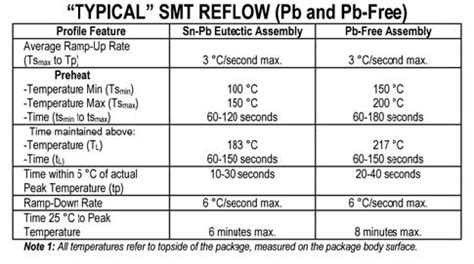

Read more: How Often Can You Raise a PCB to Lead-free Soldering Temperatures?Understanding Lead-free Soldering Temperatures Lead-free soldering is a process that involves using solder alloys that do not contain lead. This shift towards lead-free soldering is driven by environmental and health concerns associated with lead exposure. However, lead-free soldering typically requires higher temperatures compared to traditional lead-based soldering. The table below […]

-

What are specific markings?

Posted by

–

Read more: What are specific markings?

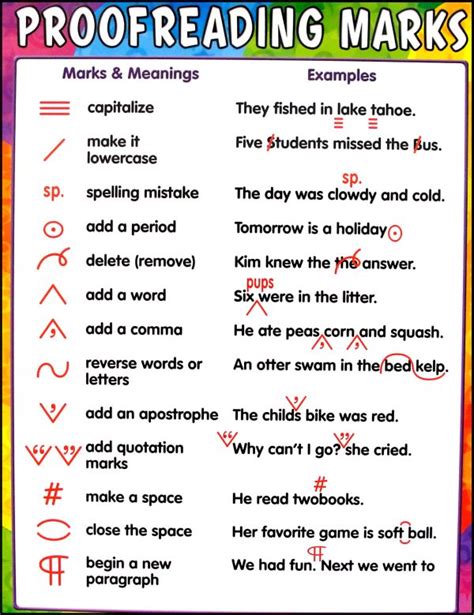

Read more: What are specific markings?Types of Specific markings There are various types of specific markings used across different industries and applications. Some of the most common categories include: Security Classification Markings Security classification markings indicate the level of sensitivity and protective measures required for information or assets. Examples include: UNCLASSIFIED CONFIDENTIAL SECRET TOP SECRET […]

-

Let’s talk about PCB Outlines

Posted by

–

Read more: Let’s talk about PCB Outlines

Read more: Let’s talk about PCB OutlinesWhat are PCB Outlines? A printed circuit board (PCB) outline refers to the physical shape and dimensions of the PCB. It defines the outer boundary and any cutouts or notches within the board. The PCB outline is a critical aspect of PCB design as it determines how the board will […]

-

What is Virtual Manufacturing or Digital Twin

Posted by

–

Read more: What is Virtual Manufacturing or Digital Twin

Read more: What is Virtual Manufacturing or Digital TwinIntroduction to Digital Twin Technology A digital twin is a virtual representation of a physical object, process, or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning, and reasoning to help decision-making. It is a powerful tool that enables manufacturers to optimize their processes, […]

-

Read more: EAGLE and DesignLink – Valuable information about components

Read more: EAGLE and DesignLink – Valuable information about componentsWhat is EAGLE? EAGLE (Easily Applicable Graphical Layout Editor) is a powerful PCB (Printed Circuit Board) design software developed by Autodesk. It is widely used by electronic designers, engineers, and hobbyists to create high-quality PCB layouts for various applications. EAGLE offers a user-friendly interface, extensive component libraries, and a wide […]

-

What is the Delivery Term?

Posted by

–

Read more: What is the Delivery Term?

Read more: What is the Delivery Term?Types of Delivery Terms There are two primary sets of delivery terms used in international trade: Incoterms (International Commercial Terms) Uniform Commercial Code (UCC) Terms Incoterms Incoterms, developed by the International Chamber of Commerce (ICC), are a set of predefined commercial terms widely used in international trade contracts. They define […]

-

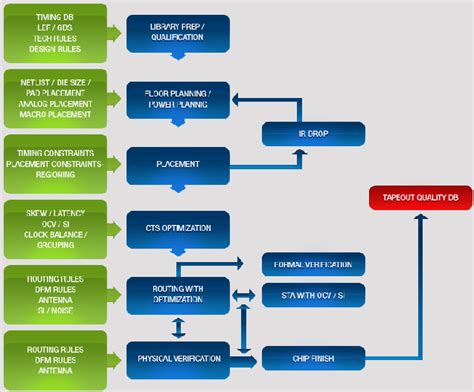

DRC Settings and Guidelines for CAD Packages

Posted by

–

Read more: DRC Settings and Guidelines for CAD Packages

Read more: DRC Settings and Guidelines for CAD PackagesIntroduction to DRC in CAD Design Rule Checking (DRC) is an essential step in the electronic design automation (EDA) process that helps ensure the manufacturability and reliability of integrated circuits (ICs) and printed circuit boards (PCBs). DRC involves verifying that a design complies with a set of predefined rules and […]