Introduction to PCB-Revisited

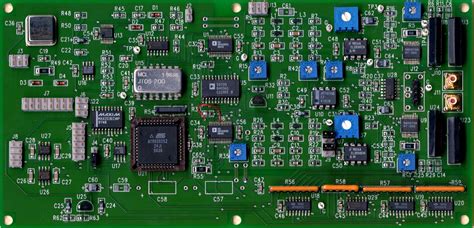

PCB (Printed Circuit Board) is an essential component in modern electronics. It serves as the foundation for mounting and connecting various electronic components to create a functional circuit. With the advancements in technology and the increasing demand for compact and efficient electronic devices, PCB design and manufacturing have undergone significant changes. In this article, we will explore the concept of PCB-Revisited, its advantages, and its applications in the latest electronic devices.

What is PCB-Revisited?

PCB-Revisited is an innovative approach to PCB design and manufacturing that focuses on optimizing the performance, reliability, and cost-effectiveness of electronic circuits. It involves the use of advanced materials, manufacturing techniques, and design methodologies to create PCBs that are more compact, efficient, and durable than traditional PCBs.

Key Features of PCB-Revisited

-

Miniaturization: PCB-Revisited enables the creation of smaller and more compact PCBs, allowing for the development of smaller electronic devices.

-

Improved Signal Integrity: The use of advanced materials and design techniques in PCB-Revisited helps to minimize signal distortion and interference, resulting in improved signal integrity.

-

Enhanced Thermal Management: PCB-Revisited incorporates effective thermal management solutions to dissipate heat efficiently, ensuring the stability and reliability of electronic components.

-

Cost-Effectiveness: By optimizing the design and manufacturing processes, PCB-Revisited helps to reduce production costs without compromising on quality.

Advantages of PCB-Revisited

1. Increased Functionality in Smaller Footprints

One of the primary advantages of PCB-Revisited is its ability to accommodate more functionality in smaller footprints. By utilizing advanced manufacturing techniques and materials, PCB-Revisited allows for the integration of more components and features into a compact PCB design. This is particularly beneficial in the development of wearable devices, IoT (Internet of Things) sensors, and other space-constrained applications.

2. Improved Signal Integrity and Reliability

PCB-Revisited focuses on improving signal integrity and reliability by minimizing signal distortion, crosstalk, and electromagnetic interference (EMI). This is achieved through the use of high-quality materials, such as low-loss dielectrics and high-performance conductors, along with advanced design techniques like controlled impedance routing and shielding. By ensuring clean and stable signal transmission, PCB-Revisited enhances the overall performance and reliability of electronic devices.

3. Enhanced Thermal Management

Effective thermal management is crucial for the longevity and reliability of electronic components. PCB-Revisited incorporates advanced thermal management solutions to dissipate heat efficiently from critical components. This can include the use of thermal vias, heat spreaders, and specialized materials with high thermal conductivity. By maintaining optimal operating temperatures, PCB-Revisited helps to prevent component failures and extends the lifespan of electronic devices.

4. Cost-Effective Manufacturing

PCB-Revisited aims to optimize the manufacturing process to achieve cost-effectiveness without compromising on quality. By leveraging advanced manufacturing techniques, such as additive manufacturing and automated assembly, PCB-Revisited reduces production time and costs. Additionally, the use of standardized components and design practices helps to streamline the manufacturing process and minimize errors, further contributing to cost savings.

Applications of PCB-Revisited

1. Wearable Electronics

PCB-Revisited plays a crucial role in the development of wearable electronics, such as smartwatches, fitness trackers, and medical monitoring devices. The miniaturization capabilities of PCB-Revisited allow for the creation of compact and lightweight PCBs that can be easily integrated into wearable form factors. Moreover, the improved signal integrity and reliability ensured by PCB-Revisited are essential for accurate data collection and transmission in wearable devices.

2. Internet of Things (IoT) Devices

The Internet of Things (IoT) has revolutionized the way we interact with everyday objects by connecting them to the internet. PCB-Revisited is instrumental in the design and manufacturing of IoT devices, such as smart home sensors, industrial monitoring systems, and connected appliances. The compact size and enhanced functionality offered by PCB-Revisited enable the development of small and efficient IoT devices that can be easily deployed in various environments.

3. Automotive Electronics

The automotive industry has witnessed a significant increase in the integration of electronic systems for safety, entertainment, and navigation purposes. PCB-Revisited plays a vital role in the development of automotive electronics by providing reliable and robust PCBs that can withstand harsh operating conditions. The improved thermal management and signal integrity features of PCB-Revisited ensure the stable and efficient operation of critical automotive systems, such as engine control units, advanced driver assistance systems (ADAS), and infotainment systems.

4. Medical Devices

PCB-Revisited is extensively used in the development of medical devices, such as patient monitoring systems, diagnostic equipment, and implantable devices. The miniaturization capabilities of PCB-Revisited allow for the creation of compact and lightweight medical devices that can be easily used in clinical settings or worn by patients. Additionally, the enhanced reliability and signal integrity provided by PCB-Revisited are crucial for accurate data acquisition and processing in medical applications.

PCB-Revisited Design Considerations

When designing PCBs using the PCB-Revisited approach, several key considerations need to be taken into account to ensure optimal performance and reliability. These considerations include:

1. Material Selection

The selection of appropriate materials is crucial in PCB-Revisited design. High-quality materials with desirable properties, such as low dielectric constant, high thermal conductivity, and excellent mechanical strength, are essential for achieving the desired performance and reliability. Some commonly used materials in PCB-Revisited include:

| Material | Dielectric Constant | Thermal Conductivity (W/mK) | Applications |

|---|---|---|---|

| FR-4 | 4.2 – 4.5 | 0.3 – 0.4 | General-purpose PCBs |

| High-Tg FR-4 | 4.2 – 4.5 | 0.3 – 0.4 | High-temperature applications |

| Polyimide | 3.4 – 3.5 | 0.2 – 0.3 | Flexible PCBs, high-temperature applications |

| Rogers RO4000 Series | 3.3 – 3.5 | 0.6 – 0.8 | High-frequency applications |

| Isola IS400 Series | 3.5 – 3.8 | 0.4 – 0.5 | High-speed digital applications |

2. Layout and Routing

Proper layout and routing techniques are essential in PCB-Revisited design to ensure signal integrity, minimize crosstalk, and reduce electromagnetic interference (EMI). Some key considerations include:

- Controlled impedance routing: Matching the impedance of traces to the characteristic impedance of the system to minimize signal reflections and distortions.

- Differential pair routing: Routing differential signals with matched lengths and spacings to maintain signal integrity.

- Ground plane and power plane design: Providing solid ground and power planes to minimize noise and ensure stable power distribution.

- Signal shielding: Implementing shielding techniques, such as ground guards and via fences, to reduce crosstalk and EMI.

3. Thermal Management

Effective thermal management is crucial in PCB-Revisited design to ensure the reliable operation of electronic components. Some thermal management techniques used in PCB-Revisited include:

- Thermal vias: Placing thermal vias near heat-generating components to conduct heat away from the PCB surface.

- Heat spreaders: Using heat spreaders, such as copper planes or metal-core substrates, to distribute heat evenly across the PCB.

- Thermal interface materials: Applying thermal interface materials, such as thermal pads or Thermal Adhesives, to enhance heat transfer between components and the PCB.

- Airflow considerations: Designing the PCB layout to optimize airflow and facilitate natural or forced convection cooling.

4. Manufacturing Process

The manufacturing process plays a significant role in the successful implementation of PCB-Revisited designs. It is essential to consider the capabilities and limitations of the chosen manufacturing process to ensure the feasibility and cost-effectiveness of the design. Some key manufacturing considerations include:

- Minimum feature sizes: Ensuring that the design complies with the minimum feature sizes supported by the manufacturing process, such as trace widths, spacings, and hole sizes.

- Layer stackup: Defining the appropriate layer stackup based on the manufacturing process and design requirements, considering factors such as signal integrity, impedance control, and manufacturability.

- Design for manufacturability (DFM): Adhering to DFM guidelines to ensure the producibility and reliability of the PCB, such as avoiding sharp angles, maintaining proper clearances, and following recommended design rules.

Future Trends in PCB-Revisited

As technology continues to advance, PCB-Revisited is expected to evolve and adapt to meet the changing demands of the electronics industry. Some future trends in PCB-Revisited include:

1. 3D Printing of PCBs

3D printing technology is gaining traction in the PCB industry, offering new possibilities for the fabrication of complex and customized PCB structures. 3D-Printed PCBs can incorporate unique geometries, embedded components, and multi-layer designs, enabling the creation of highly integrated and compact electronic devices.

2. Advanced Materials

The development of advanced materials with superior properties is expected to drive innovation in PCB-Revisited. Materials such as graphene, carbon nanotubes, and metal-organic frameworks (MOFs) are being explored for their potential applications in PCBs. These materials offer exceptional thermal conductivity, electrical conductivity, and mechanical strength, which can significantly enhance the performance and reliability of PCBs.

3. Flexible and Stretchable PCBs

The demand for flexible and stretchable electronics is growing, particularly in the fields of wearables, medical devices, and soft robotics. PCB-Revisited is adapting to accommodate these requirements by incorporating flexible substrates, stretchable conductors, and novel manufacturing techniques. Flexible and stretchable PCBs enable the creation of conformable and adaptable electronic devices that can withstand bending, stretching, and twisting.

4. Embedded Components

The integration of components directly into the PCB substrate, known as embedded components, is gaining popularity in PCB-Revisited. Embedded components, such as resistors, capacitors, and inductors, can be placed within the PCB layers, reducing the overall footprint and improving the performance of the circuit. This approach enables higher component density, shorter signal paths, and improved signal integrity.

Frequently Asked Questions (FAQ)

1. What is the difference between traditional PCBs and PCB-Revisited?

Traditional PCBs are designed and manufactured using conventional methods and materials, while PCB-Revisited incorporates advanced materials, manufacturing techniques, and design methodologies to optimize performance, reliability, and cost-effectiveness. PCB-Revisited focuses on miniaturization, improved signal integrity, enhanced thermal management, and cost-effective manufacturing.

2. What are the benefits of using PCB-Revisited in electronic devices?

PCB-Revisited offers several benefits, including increased functionality in smaller footprints, improved signal integrity and reliability, enhanced thermal management, and cost-effective manufacturing. These benefits enable the development of compact, efficient, and reliable electronic devices across various applications, such as wearables, IoT devices, automotive electronics, and medical devices.

3. What materials are commonly used in PCB-Revisited?

PCB-Revisited utilizes a range of advanced materials to achieve desired properties and performance. Some commonly used materials include high-performance FR-4 variants, polyimide for flexible PCBs, low-loss dielectrics like Rogers RO4000 series, and high-thermal-conductivity materials such as metal-core substrates. The selection of materials depends on the specific requirements of the application.

4. How does PCB-Revisited ensure signal integrity and reliability?

PCB-Revisited ensures signal integrity and reliability through the use of advanced design techniques and materials. This includes controlled impedance routing, differential pair routing, ground and power plane design, and signal shielding. By minimizing signal distortion, crosstalk, and electromagnetic interference, PCB-Revisited enables clean and stable signal transmission, resulting in improved performance and reliability of electronic devices.

5. What are some future trends in PCB-Revisited?

Some future trends in PCB-Revisited include the adoption of 3D printing technology for the fabrication of complex and customized PCB structures, the use of advanced materials like graphene and carbon nanotubes, the development of flexible and stretchable PCBs for wearable and conformable electronics, and the integration of embedded components directly into the PCB substrate for higher component density and improved performance.

Conclusion

PCB-Revisited represents a significant advancement in the field of PCB design and manufacturing. By leveraging advanced materials, manufacturing techniques, and design methodologies, PCB-Revisited enables the creation of compact, efficient, and reliable electronic devices. The benefits of PCB-Revisited, such as increased functionality, improved signal integrity, enhanced thermal management, and cost-effectiveness, make it a key enabler for various applications, including wearables, IoT devices, automotive electronics, and medical devices.

As technology continues to evolve, PCB-Revisited is expected to adapt and incorporate new trends, such as 3D printing, advanced materials, flexible and stretchable PCBs, and embedded components. These developments will further push the boundaries of PCB design and manufacturing, enabling the creation of innovative and high-performance electronic devices.

In conclusion, PCB-Revisited is a transformative approach that is revolutionizing the way PCBs are designed and manufactured. By embracing PCB-Revisited, the electronics industry can unlock new possibilities, drive innovation, and meet the ever-increasing demands for compact, efficient, and reliable electronic devices.

Leave a Reply