Introduction to PCB Noise

Printed circuit boards (PCBs) are essential components in modern electronic devices, providing a platform for mounting and interconnecting electronic components. However, PCBs can also introduce various types of noise that can degrade the performance of analog circuits. Understanding and mitigating PCB noise is crucial for designing high-performance analog systems.

Types of PCB Noise

There are several types of noise that can affect analog circuits on PCBs:

- Thermal Noise: Caused by the random motion of electrons in conductors due to temperature.

- Shot Noise: Generated by the discrete nature of electric charge carriers in semiconductors.

- Flicker Noise (1/f Noise): Low-frequency noise with a power spectral density inversely proportional to frequency.

- Power Supply Noise: Originates from fluctuations in the power supply voltage.

- Electromagnetic Interference (EMI): Caused by unwanted electromagnetic coupling between circuits or from external sources.

Thermal Noise in PCBs

Thermal noise, also known as Johnson-Nyquist noise, is present in all conductors and is caused by the random motion of electrons due to temperature. The power spectral density of thermal noise is given by:

S(f) = 4kTR

where:

– k is the Boltzmann constant (1.38 × 10^-23 J/K)

– T is the absolute temperature in Kelvin

– R is the resistance of the conductor in ohms

Reducing Thermal Noise

To minimize the impact of thermal noise in PCBs, consider the following techniques:

- Use low-noise resistors, such as metal film or wirewound types, instead of carbon composition resistors.

- Minimize the resistance of critical signal paths by using wider traces and thicker copper layers.

- Keep sensitive analog circuits away from high-temperature components or heat sources.

Shot Noise in PCBs

Shot noise is generated by the discrete nature of electric charge carriers in semiconductors, such as diodes and transistors. It is caused by the random fluctuations in the number of charge carriers crossing a potential barrier. The power spectral density of shot noise is given by:

S(f) = 2qI

where:

– q is the elementary charge (1.602 × 10^-19 C)

– I is the average current flowing through the device in amperes

Mitigating Shot Noise

To reduce the impact of shot noise in PCBs, consider the following approaches:

- Use high-quality, low-leakage semiconductors in critical analog circuits.

- Operate devices at lower currents when possible, as shot noise increases with current.

- Use parallel devices to distribute the current and reduce the noise contribution of individual devices.

Flicker Noise (1/f Noise) in PCBs

Flicker noise, also known as 1/f noise or pink noise, is a low-frequency noise with a power spectral density inversely proportional to frequency. It is present in various electronic components, including resistors, capacitors, and semiconductors. The power spectral density of flicker noise is given by:

S(f) = K / f^α

where:

– K is a device-specific constant

– f is the frequency in hertz

– α is a parameter typically close to 1

Reducing Flicker Noise

To minimize the impact of flicker noise in PCBs, consider the following strategies:

- Choose low-noise components, such as metal film resistors and polystyrene capacitors, for critical analog circuits.

- Use larger geometries for semiconductors, as flicker noise decreases with increasing device size.

- Implement Chopper stabilization or auto-zero techniques to remove low-frequency noise.

Power Supply Noise in PCBs

Power supply noise originates from fluctuations in the power supply voltage, which can affect the performance of analog circuits. It can be caused by various factors, including:

- Ripple and noise from Voltage Regulators

- Transient currents drawn by digital circuits

- Inadequate power supply decoupling

Reducing Power Supply Noise

To minimize the impact of power supply noise in PCBs, consider the following techniques:

- Use low-noise voltage regulators, such as linear regulators or low-dropout (LDO) regulators, for analog power supplies.

- Implement proper power supply decoupling using a combination of bulk, ceramic, and low-ESR capacitors.

- Separate analog and digital power supplies and ground planes to prevent noise coupling.

- Use ferrite beads or inductors to isolate analog and digital power supplies.

| Component | Capacitance | Frequency Range |

|---|---|---|

| Bulk Capacitor | 10 μF – 100 μF | 1 Hz – 100 kHz |

| Ceramic Capacitor | 0.1 μF – 1 μF | 100 kHz – 10 MHz |

| Low-ESR Capacitor | 1 μF – 10 μF | 10 MHz – 100 MHz |

Table 1: Power supply decoupling capacitor selection guide

Electromagnetic Interference (EMI) in PCBs

Electromagnetic interference (EMI) is caused by unwanted electromagnetic coupling between circuits or from external sources. It can lead to signal integrity issues, crosstalk, and degraded performance in analog circuits. EMI can be categorized into two main types:

- Conducted EMI: Propagates through conductive paths, such as power lines or signal traces.

- Radiated EMI: Propagates through the air as electromagnetic waves.

Mitigating EMI in PCBs

To reduce the impact of EMI in PCBs, consider the following approaches:

- Proper grounding techniques:

- Use a single-point ground or star ground topology for analog circuits.

- Implement ground planes to provide a low-impedance return path for high-frequency currents.

-

Connect ground planes using multiple vias to minimize impedance.

-

Shielding:

- Use shielded enclosures or shielding cans to protect sensitive analog circuits from external EMI.

-

Apply shielding gaskets or conductive adhesives to ensure proper electrical contact between shields and ground planes.

-

Circuit layout:

- Keep critical analog traces as short as possible to minimize the antenna effect.

- Route analog and digital traces perpendicular to each other to reduce crosstalk.

-

Provide adequate spacing between sensitive analog circuits and potential EMI sources.

-

Filtering:

- Implement EMI filters, such as LC filters or feedthrough capacitors, on power lines and signal interfaces.

- Use ferrite beads or common-mode chokes to suppress high-frequency noise.

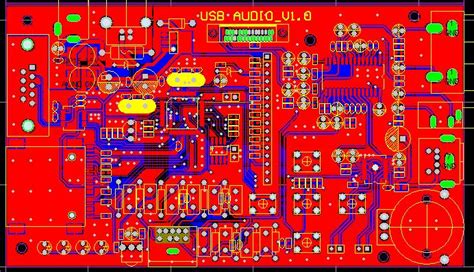

PCB Layout Techniques for Noise Reduction

Proper PCB layout is essential for minimizing noise in analog circuits. Consider the following techniques:

- Ground planes:

- Use uninterrupted ground planes to provide a low-impedance return path for currents.

-

Separate analog and digital ground planes, connecting them at a single point or through a low-impedance bridge.

-

Power planes:

- Use dedicated power planes for analog and digital circuits to reduce coupling.

-

Place power planes close to the ground plane to minimize loop area and inductance.

-

Component placement:

- Place sensitive analog components away from noisy digital circuits or power supplies.

-

Group related components together to minimize trace lengths and loop areas.

-

Trace routing:

- Route analog and digital traces on separate layers when possible.

- Avoid routing sensitive analog traces parallel to noisy traces or power lines.

-

Use trace widths appropriate for the expected current to minimize resistance and thermal noise.

-

Decoupling and filtering:

- Place decoupling capacitors close to IC power pins to minimize trace inductance.

- Use a combination of bulk, ceramic, and low-ESR capacitors for effective power supply decoupling.

- Implement LC filters or ferrite beads on power lines and signal interfaces to suppress high-frequency noise.

Frequently Asked Questions (FAQ)

-

What is the difference between thermal noise and shot noise?

Thermal noise is caused by the random motion of electrons in conductors due to temperature, while shot noise is generated by the discrete nature of electric charge carriers in semiconductors, such as diodes and transistors. -

How does power supply decoupling reduce noise in analog circuits?

Power supply decoupling reduces noise by providing a low-impedance path for high-frequency currents, minimizing voltage fluctuations on the power supply lines. It is achieved using a combination of bulk, ceramic, and low-ESR capacitors placed close to the IC power pins. -

What is the purpose of separating analog and digital ground planes in PCBs?

Separating analog and digital ground planes helps to prevent noise coupling between the two domains. By providing separate Return Paths for analog and digital currents, the noise generated by digital circuits is less likely to affect sensitive analog circuits. -

How can EMI be mitigated in PCBs?

EMI can be mitigated in PCBs through proper grounding techniques, shielding, careful circuit layout, and filtering. This includes using ground planes, shielded enclosures, routing analog and digital traces perpendicular to each other, and implementing EMI filters on power lines and signal interfaces. -

What are some best practices for PCB layout to minimize noise in analog circuits?

Best practices for PCB layout to minimize noise in analog circuits include using uninterrupted ground planes, separating analog and digital power planes, placing sensitive analog components away from noisy digital circuits, routing analog and digital traces on separate layers, and implementing effective power supply decoupling and filtering.

Conclusion

Minimizing noise in analog circuits on PCBs is crucial for achieving high-performance and reliable electronic systems. By understanding the different types of noise, such as thermal noise, shot noise, flicker noise, power supply noise, and EMI, designers can implement effective strategies to mitigate their impact.

Proper PCB layout techniques, including ground and power planes, component placement, trace routing, and decoupling and filtering, play a vital role in reducing noise coupling and ensuring signal integrity.

By following best practices and carefully considering noise sources during the design process, engineers can create PCBs that provide a robust and low-noise environment for analog circuits, enabling optimal performance in a wide range of applications.

Leave a Reply