What are PCB Prototypes?

PCB prototypes are preliminary versions of printed circuit boards that are used for testing and validation before mass production. These prototypes help engineers and designers to identify any issues or improvements needed in the design, functionality, and manufacturability of the PCB.

Key benefits of PCB prototyping:

- Design validation

- Functionality testing

- Manufacturability assessment

- Cost optimization

- Time-to-market reduction

Why are PCB Prototypes Important?

PCB prototypes play a crucial role in the development of electronic products. They allow engineers to test and refine their designs before committing to large-scale production, saving time and money in the long run.

Top reasons why PCB prototypes are essential:

- Identifying design flaws early

- Verifying electrical performance

- Testing mechanical fit and assembly

- Gathering user feedback

- Ensuring compliance with industry standards

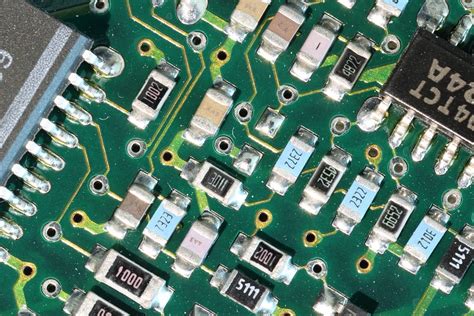

How are PCB Prototypes Made?

The process of creating PCB prototypes involves several steps, from design to fabrication. Modern PCB prototyping techniques have made it easier and faster to produce high-quality prototypes.

PCB prototyping process overview:

- Schematic design

- PCB layout

- Design review and verification

- Gerber file generation

- PCB fabrication

- Component assembly and soldering

- Testing and validation

What are the Different Types of PCB Prototypes?

There are various types of PCB prototypes, each serving a specific purpose in the development process. Understanding the differences between these prototypes can help you choose the right one for your project.

Common types of PCB prototypes:

| Type | Description | Purpose |

|---|---|---|

| Breadboard | A solderless, reusable board for temporary circuits | Quick circuit testing and experimentation |

| Stripboard | A pre-drilled PCB with copper strips for soldering components | Simple, permanent circuits for small projects |

| Perfboard | A PCB with a grid of pre-drilled holes without copper traces | Custom circuit layouts for prototyping |

| Printed Circuit Board | A custom-designed PCB with copper traces and component footprints | Final prototyping and testing before production |

What Materials are Used in PCB Prototyping?

PCB prototypes can be made from various materials, each with its own characteristics and benefits. Choosing the right material depends on factors such as the application, environment, and budget.

Common PCB prototype materials:

- FR-4 (Flame Retardant 4)

- Glass-reinforced epoxy laminate

- Most widely used material for PCBs

-

Excellent mechanical and electrical properties

-

Aluminum

- Used for PCBs that require heat dissipation

- Provides a sturdy, lightweight base for components

-

Good thermal conductivity

-

Flexible PCBs

- Made from flexible plastic substrates like polyimide

- Used in applications that require bending or folding

- Ideal for wearable electronics and compact designs

What are the Challenges in PCB Prototyping?

Creating PCB prototypes can come with its own set of challenges. Identifying and addressing these challenges early on can save time and resources in the long run.

Common challenges in PCB prototyping:

- Component availability and lead times

- Design complexity and signal integrity

- Manufacturing limitations and tolerances

- Cost and time constraints

- Regulatory compliance and certifications

How to Choose the Right PCB Prototype Manufacturer?

Selecting the right PCB prototype manufacturer is crucial for the success of your project. Consider factors such as experience, capabilities, turnaround time, and customer support when making your decision.

Key factors to consider when choosing a PCB prototype manufacturer:

- Experience and expertise in your industry

- Manufacturing capabilities and technology

- Quality control and certifications

- Turnaround time and rush options

- Customer support and communication

- Pricing and value for money

What are the Best Practices for PCB Prototype Design?

Following best practices in PCB prototype design can help ensure a smooth development process and a high-quality final product.

Essential best practices for PCB prototype design:

- Use a consistent and clear naming convention for components and nets

- Follow manufacturer guidelines for component footprints and pad sizes

- Maintain proper trace widths and spacing for signal integrity

- Use ground planes and power planes for noise reduction and power distribution

- Incorporate testability features for easy debugging and validation

- Document your design thoroughly for future reference and collaboration

How to Test and Validate PCB Prototypes?

Testing and validating PCB prototypes is essential to ensure they meet the desired specifications and performance requirements.

Key steps in PCB prototype testing and validation:

- Visual inspection for manufacturing defects and assembly issues

- Continuity testing to verify correct connections and shorts

- Power-on testing to check for proper voltage levels and current draw

- Functional testing to validate the intended operation of the circuit

- Environmental testing to assess performance under various conditions (e.g., temperature, humidity, vibration)

- Compliance testing to ensure adherence to industry standards and regulations

What are the Latest Trends in PCB Prototyping?

PCB prototyping technologies and techniques are constantly evolving to meet the demands of modern electronics. Staying up-to-date with the latest trends can help you stay competitive and innovate faster.

Current trends in PCB prototyping:

- 3D printing for rapid prototyping and custom enclosures

- Modular design approaches for flexibility and scalability

- Increased adoption of high-density interconnect (HDI) technology

- Growing use of embedded components and system-in-package (SiP) solutions

- Incorporation of IoT and wireless connectivity features

- Emphasis on eco-friendly materials and sustainable manufacturing practices

How to Optimize PCB Prototype Costs?

Optimizing PCB prototype costs is essential for budget-conscious projects and startups. Implementing cost-saving strategies can help you allocate resources more effectively without compromising quality.

Strategies for optimizing PCB prototype costs:

- Minimize PCB size and layer count

- Use standard component packages and avoid custom parts

- Opt for surface mount technology (SMT) over through-hole mounting

- Leverage economies of scale by ordering in larger quantities

- Choose a cost-effective PCB material that meets your requirements

- Work closely with your PCB prototype manufacturer to identify cost-saving opportunities

What is the Future of PCB Prototyping?

The future of PCB prototyping looks bright, with advancements in technology and manufacturing processes driving innovation and efficiency.

Emerging developments in PCB prototyping:

- Increased automation and AI-driven design tools

- Growing adoption of additive manufacturing techniques

- Integration of advanced materials like graphene and carbon nanotubes

- Expansion of flexible and stretchable electronics applications

- Development of self-healing and self-assembling PCBs

- Emphasis on cybersecurity and tamper-proof designs

Frequently Asked Questions (FAQ)

-

Q: How long does it take to create a PCB prototype?

A: The turnaround time for PCB prototypes varies depending on the complexity of the design, the chosen manufacturer, and the production method. Typical lead times range from 24 hours to 2 weeks. -

Q: What is the minimum order quantity (MOQ) for PCB prototypes?

A: Many PCB prototype manufacturers offer low MOQs, sometimes as low as one piece. However, larger quantities often result in lower per-unit costs. -

Q: Can I use my own components for PCB prototyping?

A: Yes, most PCB prototype manufacturers allow customers to provide their own components. This is known as consigned parts or customer-supplied parts. -

Q: What file formats are required for PCB prototyping?

A: The most common file formats for PCB prototyping are Gerber files (RS-274X) and drill files (Excellon). Some manufacturers also accept CAD files from popular PCB design software. -

Q: How can I ensure the quality of my PCB prototypes?

A: To ensure the quality of your PCB prototypes, work with a reputable manufacturer that follows strict quality control processes. Provide clear and accurate design files, and communicate your requirements effectively. Thoroughly test and validate your prototypes before moving to mass production.

In conclusion, PCB prototypes are an essential part of the electronic product development process. By understanding the various aspects of PCB prototyping, from design to manufacturing and testing, you can create high-quality prototypes that meet your project requirements and help bring your ideas to life.

Leave a Reply