What is a PCB Prototype?

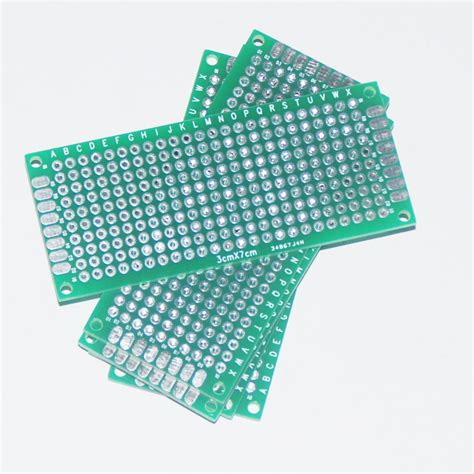

A PCB (Printed Circuit Board) prototype is a preliminary version of a PCB designed to test and validate the functionality, performance, and manufacturability of the final product. It is an essential step in the PCB development process, allowing engineers and designers to identify and rectify any issues before mass production.

PCB prototypes are typically created using the same materials and manufacturing processes as the final product, ensuring that the prototype closely resembles the intended design. This enables developers to conduct thorough testing and make necessary adjustments to optimize the PCB’s performance.

Types of PCB Prototypes

There are several types of PCB prototypes, each serving a specific purpose in the development process:

-

Visual Prototype: A non-functional model that represents the physical appearance and dimensions of the final PCB. It helps in assessing the board’s layout and form factor.

-

Proof-of-Concept (POC) Prototype: A functional prototype that demonstrates the basic working principles of the PCB. It may not include all the features of the final product but serves to validate the concept.

-

Working Prototype: A fully functional prototype that includes all the features and components of the final PCB. It undergoes rigorous testing to ensure it meets the desired specifications and performance criteria.

-

Pre-Production Prototype: A prototype that closely resembles the final product and is used for final testing and certification before mass production begins.

Why You Need a PCB Prototype

1. Design Validation

A PCB prototype allows you to validate your design and ensure that it functions as intended. By testing the prototype, you can identify any design flaws, such as incorrect component placement, signal integrity issues, or power distribution problems. This enables you to make necessary changes to the design before proceeding with mass production, saving time and money in the long run.

2. Performance Testing

Prototyping enables you to test the PCB’s performance under various conditions, such as different temperatures, humidity levels, and electrical loads. This helps in identifying any performance bottlenecks or reliability issues that may arise during real-world use. By conducting thorough performance testing, you can optimize the PCB’s design to meet the desired specifications and ensure its reliability.

3. Manufacturability Assessment

Creating a PCB prototype allows you to assess the manufacturability of your design. You can identify any potential manufacturing challenges, such as component sourcing issues, assembly difficulties, or compatibility problems with the chosen manufacturing process. By addressing these issues early in the development process, you can streamline the mass production phase and avoid costly delays or rework.

4. Cost Optimization

Prototyping helps in optimizing the cost of your PCB. By identifying and rectifying design issues early on, you can avoid the need for expensive rework or redesign during mass production. Additionally, prototyping allows you to experiment with different materials, components, and manufacturing processes to find the most cost-effective solution that meets your performance and reliability requirements.

5. Time-to-Market Acceleration

By creating a PCB prototype, you can accelerate your time-to-market by identifying and addressing potential issues early in the development process. This reduces the risk of delays during mass production and ensures that your product reaches the market faster. Prototyping also allows you to gather valuable feedback from potential customers or stakeholders, enabling you to make necessary adjustments to the design before finalizing the product.

The PCB Prototyping Process

The PCB prototyping process typically involves the following steps:

-

Design Creation: The PCB design is created using specialized software, such as EDA (Electronic Design Automation) tools. The design includes the schematic, component placement, and routing of the PCB.

-

Design Review: The PCB design undergoes a thorough review process to ensure it meets the desired specifications and design guidelines. Any issues or potential improvements are identified and addressed at this stage.

-

Prototype Fabrication: The PCB prototype is fabricated using the chosen manufacturing process, such as traditional etching or advanced techniques like 3D printing. The fabrication process includes creating the PCB substrate, applying the conductive traces, and adding any necessary components.

-

Assembly: The PCB prototype is assembled by soldering the components onto the board. This step requires precision and expertise to ensure proper placement and connection of the components.

-

Testing and Validation: The assembled PCB prototype undergoes rigorous testing to validate its functionality, performance, and reliability. This may include electrical testing, environmental testing, and compatibility testing with other components or systems.

-

Iteration and Refinement: Based on the testing results, any necessary changes or improvements are made to the PCB design. This iterative process continues until the prototype meets all the desired specifications and performance criteria.

Choosing the Right PCB Prototyping Service

When selecting a PCB prototyping service, consider the following factors:

-

Experience and Expertise: Choose a service provider with extensive experience in PCB prototyping and a proven track record of delivering high-quality prototypes.

-

Manufacturing Capabilities: Ensure that the service provider has the necessary manufacturing capabilities to create your specific PCB prototype, including the ability to work with your chosen materials and components.

-

Turnaround Time: Consider the service provider’s turnaround time for prototyping, as this can impact your overall development timeline. Look for providers that offer fast and reliable prototyping services.

-

Cost: Compare the costs of different PCB prototyping services to find the most cost-effective solution that meets your budget constraints. However, be cautious of sacrificing quality for lower costs.

-

Customer Support: Choose a service provider that offers excellent customer support, including technical assistance, design guidance, and prompt communication throughout the prototyping process.

| Factor | Importance | Description |

|---|---|---|

| Experience & Expertise | High | Ensures high-quality prototypes and reliable service |

| Manufacturing Capabilities | High | Ability to work with specific materials and components |

| Turnaround Time | Medium | Impacts development timeline; fast and reliable prototyping is preferable |

| Cost | Medium | Cost-effective solution that meets budget constraints without sacrificing quality |

| Customer Support | High | Technical assistance, design guidance, and prompt communication during prototyping |

Frequently Asked Questions (FAQ)

-

Q: How long does it take to create a PCB prototype?

A: The turnaround time for PCB prototyping varies depending on the complexity of the design and the chosen service provider. Generally, prototyping can take anywhere from a few days to several weeks. Some service providers offer expedited prototyping services for faster turnaround times. -

Q: How much does PCB prototyping cost?

A: The cost of PCB prototyping depends on several factors, such as the complexity of the design, the chosen materials and components, and the number of prototypes required. Prices can range from a few hundred to several thousand dollars. It’s essential to obtain quotes from multiple service providers and compare the costs based on your specific requirements. -

Q: Can I create a PCB prototype myself?

A: While it is possible to create a PCB prototype yourself, it requires specialized knowledge, skills, and equipment. DIY PCB prototyping can be challenging and time-consuming, especially for complex designs. It’s generally recommended to use professional PCB prototyping services to ensure high-quality and reliable prototypes. -

Q: What files do I need to provide for PCB prototyping?

A: To create a PCB prototype, you typically need to provide the following files: - Gerber files: These are the industry-standard files that contain the PCB layout information, including the copper layers, solder mask, and silkscreen.

- Drill files: These files specify the location and size of the holes in the PCB.

- Bill of Materials (BOM): A list of all the components used in the PCB design, including their quantities and specifications.

-

Assembly drawings: Detailed illustrations showing the placement and orientation of components on the PCB.

-

Q: How many prototypes should I create?

A: The number of prototypes you should create depends on your specific needs and the complexity of the design. In general, it’s recommended to create at least a few prototypes to allow for thorough testing and validation. Some designers prefer to create multiple iterations of prototypes to refine the design incrementally. Discuss your prototyping requirements with your chosen service provider to determine the optimal number of prototypes for your project.

Conclusion

PCB prototyping is a crucial step in the development of electronic products. It allows designers and engineers to validate their designs, test performance, assess manufacturability, optimize costs, and accelerate time-to-market. By creating a PCB prototype, you can identify and address potential issues early in the development process, ensuring a smooth transition to mass production.

When choosing a PCB prototyping service, consider factors such as experience, manufacturing capabilities, turnaround time, cost, and customer support. By selecting the right service provider, you can ensure high-quality prototypes that meet your specific requirements and help bring your electronic product to market successfully.

Leave a Reply