What is a PCB Printer?

A PCB printer is a specialized machine that combines the functionality of a traditional printer with the precision and accuracy required for manufacturing circuit boards. These printers use advanced inkjet technology to deposit conductive ink or paste onto a substrate, creating the intricate patterns of circuits and components that make up a PCB.

PCB printers offer several advantages over traditional PCB manufacturing methods, such as:

- Faster production times

- Lower costs

- Increased design flexibility

- Improved accuracy and precision

- Reduced waste and environmental impact

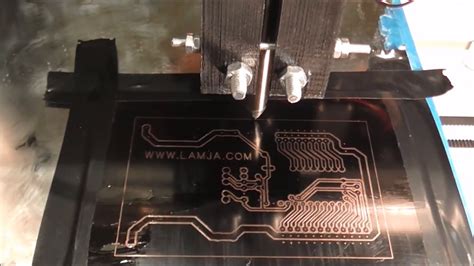

How PCB Printers Work

PCB printers typically consist of three main components: the printhead, the substrate, and the software that controls the printing process.

-

Printhead: The printhead is the core component of a PCB printer. It houses the nozzles that dispense the conductive ink or paste onto the substrate. The number of nozzles and their arrangement can vary depending on the printer model and the specific application.

-

Substrate: The substrate is the base material on which the circuit board is printed. It can be made of various materials, such as FR-4, polyimide, or flexible substrates like PET or PEN. The choice of substrate depends on the intended use of the PCB and the required electrical and mechanical properties.

-

Software: PCB printers rely on specialized software to control the printing process. This software converts the PCB design files into instructions for the printer, determining the placement of components, the routing of traces, and the overall layout of the board.

During the printing process, the substrate is fed into the printer, and the printhead moves across the surface, depositing the conductive ink or paste according to the instructions provided by the software. The printer may make multiple passes to build up the required thickness of the conductive traces and to ensure proper coverage.

After printing, the PCB undergoes a curing process to solidify the conductive material and ensure its adhesion to the substrate. This can be done using heat, UV light, or a combination of both, depending on the type of ink or paste used.

Advantages of PCB Printers

PCB printers offer several key advantages over traditional PCB manufacturing methods, making them an attractive option for both small-scale prototyping and large-scale production.

Faster Production Times

One of the most significant advantages of PCB printers is their ability to significantly reduce production times. Traditional PCB manufacturing methods, such as etching and milling, can be time-consuming and labor-intensive. In contrast, PCB printers can produce a fully functional circuit board in a matter of hours, depending on the complexity of the design.

This rapid prototyping capability allows manufacturers to quickly iterate on their designs, test new concepts, and bring products to market faster. It also enables more efficient use of resources, as there is less downtime between design cycles.

Lower Costs

PCB printers can also help manufacturers reduce their production costs. Traditional PCB manufacturing methods require significant investments in equipment, materials, and skilled labor. PCB printers, on the other hand, have a lower initial cost and require fewer consumables, making them a more cost-effective solution in the long run.

Additionally, the ability to produce smaller batches of PCBs on-demand helps manufacturers avoid the costs associated with maintaining large inventories of pre-manufactured boards.

Increased Design Flexibility

PCB printers offer greater design flexibility compared to traditional manufacturing methods. With the ability to print on a variety of substrates and the precision to create intricate patterns, PCB printers enable manufacturers to explore new designs and push the boundaries of what is possible with circuit boards.

This flexibility is particularly valuable in industries where space is at a premium, such as wearable technology and the Internet of Things (IoT). PCB printers can create smaller, more compact boards that can be integrated into these devices without compromising functionality.

Improved Accuracy and Precision

PCB printers are capable of producing circuit boards with exceptional accuracy and precision. The use of advanced inkjet technology allows for the creation of fine-pitch traces and the precise placement of components, resulting in higher-quality PCBs with improved reliability.

This level of precision is essential in applications where even the slightest deviation can lead to device failure, such as in the aerospace and medical industries.

Reduced Waste and Environmental Impact

Traditional PCB manufacturing methods can generate significant amounts of waste, including excess materials and hazardous chemicals. PCB printers, in contrast, are a more environmentally friendly solution.

By depositing only the required amount of conductive material and using fewer harmful chemicals, PCB printers reduce waste and minimize the environmental impact of circuit board production. This not only benefits the environment but also helps manufacturers comply with increasingly stringent environmental regulations.

Applications of PCB Printers

PCB printers have a wide range of applications across various industries, from consumer electronics to aerospace and defense. Some of the most common applications include:

-

Prototyping and Small-Batch Production: PCB printers are ideal for rapid prototyping and small-batch production, allowing manufacturers to quickly test new designs and produce limited quantities of boards for testing and evaluation.

-

Wearable Technology: The ability to print on flexible substrates makes PCB printers well-suited for creating circuit boards for wearable devices, such as smartwatches, fitness trackers, and medical monitoring equipment.

-

Internet of Things (IoT): PCB printers can produce the small, compact boards required for IoT devices, enabling the creation of smart homes, connected vehicles, and industrial automation systems.

-

Aerospace and Defense: The high precision and reliability of PCBs produced by printers make them suitable for use in critical aerospace and defense applications, where failure is not an option.

-

Medical Devices: PCB printers can create the complex, high-density boards required for advanced medical devices, such as implantable sensors and diagnostic equipment.

Choosing the Right PCB Printer

When selecting a PCB printer, there are several factors to consider to ensure that it meets your specific manufacturing needs. These include:

-

Print Resolution: The print resolution determines the minimum feature size that the printer can produce. Higher resolutions allow for the creation of finer traces and more complex designs.

-

Substrate Compatibility: Ensure that the printer is compatible with the substrates you intend to use, whether they are rigid or flexible.

-

Ink or Paste Compatibility: Different PCB printers may require specific types of conductive inks or pastes. Make sure that the printer you choose is compatible with the materials you plan to use.

-

Software Integration: Consider how well the printer’s software integrates with your existing design tools and workflows.

-

Maintenance and Support: Evaluate the level of maintenance required for the printer and the availability of support from the manufacturer.

| Factor | Considerations |

|---|---|

| Print Resolution | Minimum feature size, trace width, and spacing |

| Substrate Compatibility | Rigid substrates (FR-4, polyimide) or flexible substrates (PET, PEN) |

| Ink or Paste Compatibility | Type of conductive material required (nanoparticle, metal complex, etc.) |

| Software Integration | Compatibility with existing design tools and workflows |

| Maintenance and Support | Required maintenance intervals and availability of manufacturer support |

The Future of PCB Printers

As technology continues to advance, PCB printers are poised to play an increasingly important role in the electronics manufacturing industry. Some of the key trends and developments to watch include:

-

Increased Adoption: As awareness of the benefits of PCB printers grows, more manufacturers are likely to adopt this technology, driving down costs and increasing availability.

-

Improved Materials: Advances in conductive inks and pastes will enable the creation of even more complex and high-performance PCBs.

-

Integration with Additive Manufacturing: Combining PCB printing with other additive manufacturing techniques, such as 3D printing, could enable the creation of fully integrated electronic devices in a single process.

-

Automation and Industry 4.0: The integration of PCB printers with automated assembly lines and smart factory systems will further streamline the production process and improve overall efficiency.

As these trends continue to shape the industry, PCB printers are expected to become an indispensable tool for electronics manufacturers, enabling faster, more cost-effective, and more innovative circuit board production.

Frequently Asked Questions (FAQ)

-

Q: How long does it take to print a PCB using a PCB printer?

A: The time required to print a PCB depends on the complexity of the design and the specific printer being used. However, most PCB printers can produce a functional board in a matter of hours, significantly faster than traditional manufacturing methods. -

Q: Can PCB printers create multi-layer boards?

A: Yes, some advanced PCB printers are capable of creating multi-layer boards by printing and curing each layer successively. However, the number of layers and the complexity of the design may be limited compared to traditional multi-layer PCB manufacturing methods. -

Q: Are the PCBs produced by printers as reliable as those made with traditional methods?

A: When using high-quality materials and following proper printing and curing procedures, PCBs produced by printers can be just as reliable as those made with traditional methods. In some cases, the increased precision and accuracy of PCB printers can even result in higher-quality boards. -

Q: Can PCB printers be used for high-volume production?

A: While PCB printers are well-suited for prototyping and small-batch production, they can also be used for high-volume production. The speed and efficiency of PCB printers make them a viable option for larger-scale manufacturing, especially when combined with automated assembly processes. -

Q: Are PCB printers expensive?

A: The initial cost of a PCB printer can be higher than traditional PCB manufacturing equipment. However, the long-term cost savings in terms of reduced labor, faster production times, and lower material consumption can make PCB printers a cost-effective solution for many manufacturers.

In conclusion, PCB printers represent a significant advancement in circuit board manufacturing, offering faster production times, lower costs, increased design flexibility, improved accuracy, and reduced environmental impact. As the technology continues to evolve and more manufacturers adopt PCB printers, we can expect to see even more innovative and high-performance electronic devices in the future.

Leave a Reply