What are Digital Sensors?

Digital sensors are devices that convert physical quantities such as temperature, pressure, light, or sound into digital signals that can be processed by electronic systems. Unlike analog sensors, which output continuous voltage or current signals, digital sensors produce discrete digital outputs that can be easily interpreted by microcontrollers or computers.

Advantages of Digital Sensors

Digital sensors offer several advantages over their analog counterparts:

- Improved accuracy and precision

- Reduced noise and interference

- Easier integration with digital systems

- Simplified signal processing and data transmission

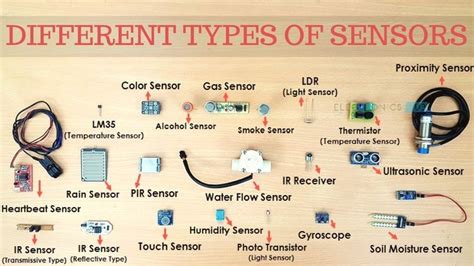

Types of Digital Sensors

There are numerous types of digital sensors, each designed to measure specific physical quantities. Let’s explore some common examples:

1. Temperature Sensors

Digital temperature sensors measure the ambient temperature and convert it into a digital signal. They are used in various applications, such as:

- Environmental monitoring

- HVAC systems

- Consumer appliances (e.g., refrigerators, ovens)

- Industrial process control

Some popular digital temperature sensors include:

| Sensor | Description | Temperature Range |

|---|---|---|

| DS18B20 | 1-Wire digital thermometer | -55°C to +125°C |

| LM75A | I2C digital temperature sensor | -55°C to +125°C |

| TMP102 | Low-power digital temperature sensor | -40°C to +125°C |

2. Pressure Sensors

Digital pressure sensors measure the force applied to a specific area and convert it into a digital signal. They are commonly used in:

- Automotive systems (e.g., tire pressure monitoring)

- Medical devices (e.g., blood pressure monitors)

- Industrial automation (e.g., pneumatic systems)

Examples of digital pressure sensors include:

| Sensor | Description | Pressure Range |

|---|---|---|

| MPX4250 | Integrated silicon pressure sensor | 20 to 250 kPa |

| BMP280 | Barometric pressure sensor | 300 to 1100 hPa |

| MS5803-14BA | High-resolution pressure sensor | 0 to 14 bar |

3. Light Sensors

Digital light sensors detect the intensity of light in the environment and convert it into a digital signal. They are used in applications such as:

- Ambient light sensing in mobile devices

- Automatic brightness control in displays

- Optical encoders

Some common digital light sensors are:

| Sensor | Description | Spectral Range |

|---|---|---|

| TSL2561 | Light-to-digital converter | Visible to IR |

| BH1750 | Ambient light sensor | Visible |

| VEML6070 | UV light sensor | UVA (320-410 nm) |

4. Sound Sensors

Digital sound sensors, also known as microphones, convert sound waves into digital signals. They are used in:

- Voice recognition systems

- Audio recording devices

- Acoustic sensors

Examples of digital sound sensors include:

| Sensor | Description | Frequency Range |

|---|---|---|

| INMP441 | Omnidirectional MEMS microphone | 60 Hz to 15 kHz |

| MP34DT01 | Digital MEMS microphone | 20 Hz to 20 kHz |

| SPH0645 | I2S digital microphone | 50 Hz to 15 kHz |

5. Accelerometers

Digital accelerometers measure the acceleration forces acting on an object and convert them into digital signals. They are used in:

- Motion sensing in mobile devices

- Wearable fitness trackers

- Vehicle stability control systems

Some popular digital accelerometers are:

| Sensor | Description | Measurement Range |

|---|---|---|

| ADXL345 | 3-axis accelerometer | ±2g, ±4g, ±8g, ±16g |

| MPU-6050 | 6-axis accelerometer and gyroscope | ±2g, ±4g, ±8g, ±16g |

| LIS3DH | Low-power 3-axis accelerometer | ±2g, ±4g, ±8g, ±16g |

How Do Digital Sensors Work?

Digital sensors typically consist of sensing elements that respond to physical stimuli and convert them into electrical signals. These signals are then conditioned, amplified, and converted into digital form using analog-to-digital converters (ADCs).

The digital output can be in various formats, such as:

- Pulse-Width Modulation (PWM)

- Inter-Integrated Circuit (I2C)

- Serial Peripheral Interface (SPI)

- 1-Wire

The digital data is then transmitted to a microcontroller or computer for further processing and analysis.

Applications of Digital Sensors

Digital sensors find applications in a wide range of fields, including:

1. Consumer Electronics

- Smartphones and tablets (e.g., accelerometers, light sensors)

- Wearable devices (e.g., fitness trackers, smartwatches)

- Home automation systems (e.g., temperature sensors, motion sensors)

2. Automotive

- Engine management systems (e.g., pressure sensors, temperature sensors)

- Advanced driver assistance systems (ADAS) (e.g., radar, lidar)

- Tire pressure monitoring systems (TPMS)

3. Industrial Automation

- Process control (e.g., temperature, pressure, flow sensors)

- Machine condition monitoring (e.g., Vibration Sensors)

- Robotics and automation systems

4. Healthcare

- Medical devices (e.g., blood pressure monitors, pulse oximeters)

- Remote patient monitoring

- Wearable health trackers

5. Environmental Monitoring

- Weather stations (e.g., temperature, humidity, Barometric Pressure Sensors)

- Air and water quality monitoring

- Precision agriculture (e.g., Soil Moisture Sensors)

Integrating Digital Sensors with Microcontrollers

To use digital sensors in a project, you’ll need to integrate them with a microcontroller or single-board computer. Here’s a general process for integrating a digital sensor:

- Choose a microcontroller or single-board computer (e.g., Arduino, Raspberry Pi)

- Select a digital sensor compatible with your microcontroller and application

- Connect the sensor to the microcontroller using the appropriate communication protocol (e.g., I2C, SPI, 1-Wire)

- Install necessary libraries or drivers for the sensor

- Write code to initialize the sensor, read the digital data, and process it according to your application requirements

- Test and calibrate the sensor as needed

Frequently Asked Questions (FAQ)

1. What is the difference between analog and digital sensors?

Analog sensors output continuous voltage or current signals that are proportional to the measured physical quantity. Digital sensors, on the other hand, convert the physical quantity into discrete digital signals that can be easily processed by electronic systems.

2. How do I choose the right digital sensor for my application?

When selecting a digital sensor, consider factors such as the physical quantity to be measured, measurement range, accuracy, resolution, power consumption, communication interface, and compatibility with your microcontroller or system.

3. Can digital sensors be used in harsh environments?

Yes, many digital sensors are designed to operate in harsh environments, such as high temperatures, vibrations, or corrosive atmospheres. Look for sensors with appropriate environmental ratings and protective enclosures.

4. How do I calibrate a digital sensor?

Calibration procedures vary depending on the sensor type and application. Generally, you’ll need to expose the sensor to known reference values and adjust its output accordingly. Refer to the sensor’s datasheet or application notes for specific calibration instructions.

5. What are some common communication protocols used by digital sensors?

Common communication protocols used by digital sensors include:

- Inter-Integrated Circuit (I2C)

- Serial Peripheral Interface (SPI)

- 1-Wire

- Universal Asynchronous Receiver/Transmitter (UART)

- Pulse-width modulation (PWM)

Choose a sensor with a communication protocol compatible with your microcontroller or system.

Conclusion

Digital sensors are essential components in a wide range of applications, enabling the measurement and monitoring of various physical quantities. By understanding the different types of digital sensors, their working principles, and integration methods, you can effectively incorporate them into your projects and systems.

As technology continues to advance, digital sensors will become increasingly sophisticated, offering higher accuracy, lower power consumption, and better integration with digital systems. Staying up-to-date with the latest developments in digital sensor technology will help you create innovative solutions and stay competitive in your field.

Leave a Reply