Introduction to PCB Assembly

PCB assembly is the process of assembling electronic components onto a printed circuit board (PCB) to create a functional electronic device. The process involves several steps, including placing components on the PCB, soldering them in place, and testing the assembled board for proper functionality.

Types of PCB Assembly

There are two main types of PCB assembly:

-

Through-Hole Assembly (THA): In this method, component leads are inserted through holes drilled in the PCB and soldered to pads on the opposite side.

-

Surface Mount Assembly (SMA): This method involves placing components directly onto pads on the surface of the PCB and soldering them in place.

Advantages of PCB Assembly

PCB assembly offers several advantages, including:

- Miniaturization of electronic devices

- Improved reliability and durability

- Reduced manufacturing costs

- Faster production times

The PCB Assembly Process

Step 1: PCB Design and Fabrication

The first step in the PCB assembly process is designing and fabricating the PCB. This involves creating a schematic diagram of the electronic circuit, laying out the components on the board, and generating files for PCB fabrication.

Step 2: Solder Paste Application

Once the PCB is fabricated, solder paste is applied to the pads where components will be placed. This is typically done using a stencil and a solder paste printer.

Step 3: Component Placement

Next, the electronic components are placed onto the PCB using a pick-and-place machine. This machine uses a vacuum nozzle to pick up components from a reel or tray and place them onto the solder paste on the PCB.

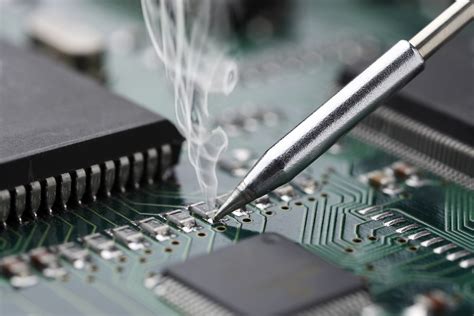

Step 4: Reflow Soldering

After the components are placed, the PCB goes through a reflow soldering process. The board is heated in an oven, causing the solder paste to melt and form a strong bond between the components and the PCB pads.

Step 5: Inspection and Testing

Finally, the assembled PCB is inspected for any defects or errors, such as misaligned components or solder bridges. The board is then tested to ensure proper functionality before being packaged and shipped to the customer.

IMS Pool PCB Assembly Services

IMS Pool is a leading provider of PCB assembly services, offering a wide range of capabilities to meet the needs of customers across various industries.

PCB Assembly Capabilities

| Capability | Description |

|---|---|

| SMT Assembly | Surface mount technology assembly for small to medium-sized components |

| Through-Hole Assembly | Traditional through-hole assembly for larger components and connectors |

| Mixed Technology Assembly | Combination of SMT and through-hole assembly for complex designs |

| BGA and CSP Assembly | Ball grid array and chip scale package assembly for high-density designs |

| Prototype Assembly | Quick-turn prototype assembly for design validation and testing |

| Low-Volume Production | Small to medium-volume production runs for niche applications |

| High-Volume Production | Large-volume production runs for mass-market products |

Quality Control and Testing

IMS Pool is committed to delivering high-quality PCB assemblies to its customers. To ensure this, the company employs a comprehensive quality control and testing process that includes:

- Automated optical inspection (AOI)

- X-ray inspection

- In-circuit testing (ICT)

- Functional testing

- Burn-in testing

- Environmental testing

Customer Support and Service

IMS Pool prides itself on providing exceptional customer support and service throughout the PCB assembly process. The company offers:

- Dedicated project management

- Design for manufacturability (DFM) analysis

- Rapid prototyping

- Flexible production scheduling

- Inventory management

- Global shipping and logistics

Benefits of Outsourcing PCB Assembly

Outsourcing PCB assembly to a trusted partner like IMS Pool offers several benefits, including:

Cost Savings

By outsourcing PCB assembly, companies can save on capital expenses associated with purchasing and maintaining assembly equipment and facilities. Additionally, outsourcing allows companies to take advantage of economies of scale and access lower component pricing through their assembly partner’s purchasing power.

Faster Time to Market

Outsourcing PCB assembly can significantly reduce lead times, allowing companies to bring their products to market faster. Assembly partners like IMS Pool have streamlined processes and dedicated resources that enable them to complete assembly projects quickly and efficiently.

Access to Expertise

PCB assembly requires specialized knowledge and skills that may not be available in-house. By outsourcing to an experienced assembly partner, companies can access a team of experts who can provide guidance on design, component selection, and manufacturing best practices.

Flexibility and Scalability

Outsourcing PCB assembly provides companies with greater flexibility and scalability to respond to changing market demands. Assembly partners can quickly ramp up or down production as needed, allowing companies to avoid the costs and risks associated with maintaining excess capacity or inventory.

Choosing the Right PCB Assembly Partner

When selecting a PCB assembly partner, there are several factors to consider:

Technical Capabilities

Choose a partner with the technical capabilities and expertise to handle your specific assembly requirements. Look for a partner with experience in your industry and with the types of components and technologies used in your designs.

Quality and Reliability

Ensure that your assembly partner has a robust quality control and testing process in place to deliver consistent, reliable results. Look for certifications such as ISO 9001 and IPC-A-610, as well as a track record of successful projects.

Communication and Support

Effective communication and support are critical to the success of any PCB assembly project. Choose a partner that is responsive, proactive, and willing to work closely with your team to ensure project success.

Cost and Value

While cost is an important consideration, it should not be the only factor in choosing an assembly partner. Look for a partner that offers competitive pricing while also delivering value through quality, reliability, and support.

Conclusion

PCB assembly is a critical process in the production of electronic devices, and choosing the right assembly partner is essential to ensuring project success. IMS Pool offers a comprehensive range of PCB assembly services, backed by a commitment to quality, reliability, and customer support. By outsourcing PCB assembly to a trusted partner like IMS Pool, companies can save costs, reduce lead times, and access specialized expertise to bring their products to market faster and more efficiently.

Frequently Asked Questions (FAQ)

1. What is the minimum order quantity for PCB assembly at IMS Pool?

There is no minimum order quantity for PCB assembly at IMS Pool. We offer services for prototype, low-volume, and high-volume production runs to meet the needs of customers of all sizes.

2. How long does the PCB assembly process typically take?

The lead time for PCB assembly depends on the complexity of the design, the availability of components, and the production volume. Prototype assemblies can typically be completed in 5-7 days, while production runs may take 2-3 weeks or longer.

3. What types of components can be assembled onto a PCB?

IMS Pool has experience assembling a wide range of components onto PCBs, including surface mount devices (SMDs), through-hole components, ball grid arrays (BGAs), chip scale packages (CSPs), and more. We can handle components as small as 01005 and as large as 55mm x 55mm.

4. How does IMS Pool ensure the quality of its PCB assemblies?

IMS Pool employs a comprehensive quality control and testing process that includes automated optical inspection (AOI), X-ray inspection, in-circuit testing (ICT), functional testing, burn-in testing, and environmental testing. We are ISO 9001 certified and adhere to IPC-A-610 standards for electronic assemblies.

5. Can IMS Pool provide design assistance for PCB assembly projects?

Yes, IMS Pool offers design for manufacturability (DFM) analysis and can provide guidance on component selection, placement, and routing to optimize your design for assembly. We work closely with our customers to ensure that their designs are both functional and manufacturable.

Leave a Reply