Introduction to PCB materials

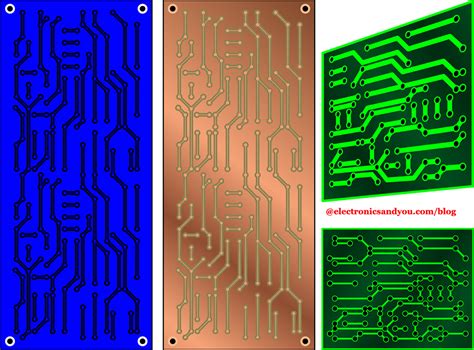

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing a reliable and efficient means of connecting electronic components. The choice of materials used in PCB Fabrication plays a crucial role in determining the performance, durability, and cost of the final product. In this comprehensive article, we will explore the various types of PCB materials, their properties, and their applications.

Types of PCB Materials

FR-4

FR-4 is the most commonly used PCB material, consisting of a glass-reinforced epoxy laminate. It offers excellent mechanical and electrical properties, making it suitable for a wide range of applications.

Advantages of FR-4

- Good dielectric properties

- High mechanical strength

- Excellent thermal stability

- Cost-effective

Disadvantages of FR-4

- Higher dielectric loss compared to some other materials

- Limited high-frequency performance

Rogers Materials

Rogers materials are high-performance PCB substrates designed for demanding applications, such as RF and microwave circuits. They offer superior dielectric properties and low loss, making them ideal for high-frequency applications.

Common Rogers Materials

- RO4003C: A hydrocarbon ceramic laminate with low dielectric loss and stable dielectric constant

- RO4350B: A glass-reinforced hydrocarbon ceramic laminate with low loss and good thermal stability

- RT/duroid 5870: A glass microfiber-reinforced PTFE composite with low dielectric loss and good thermal stability

Advantages of Rogers Materials

- Low dielectric loss

- Stable dielectric constant

- Excellent high-frequency performance

Disadvantages of Rogers Materials

- Higher cost compared to FR-4

- More difficult to process and fabricate

Polyimide

Polyimide is a high-performance polymer used in PCBs that require excellent thermal stability and mechanical strength. It is often used in aerospace, military, and high-temperature applications.

Advantages of Polyimide

- High thermal stability (up to 260°C)

- Excellent mechanical strength

- Good chemical resistance

Disadvantages of Polyimide

- Higher cost compared to FR-4

- More difficult to process and fabricate

Flexible PCB Materials

Flexible PCBs require special materials that can withstand repeated bending and flexing without damage. Common flexible PCB materials include polyimide, polyester, and PEEK.

Advantages of Flexible PCB Materials

- Ability to conform to various shapes and sizes

- Lightweight and space-saving

- Improved shock and vibration resistance

Disadvantages of Flexible PCB Materials

- Higher cost compared to rigid PCB materials

- More complex fabrication process

Properties of PCB Materials

Dielectric Constant (Dk)

The dielectric constant (Dk) is a measure of a material’s ability to store electrical energy. A lower Dk value indicates better signal integrity and higher-frequency performance.

| Material | Dielectric Constant (Dk) |

|---|---|

| FR-4 | 4.2 – 4.5 |

| RO4003C | 3.38 |

| RO4350B | 3.48 |

| RT/duroid 5870 | 2.33 |

| Polyimide | 3.4 – 3.5 |

Dissipation Factor (Df)

The dissipation factor (Df) is a measure of a material’s loss tangent, which represents the amount of energy lost as heat when an AC signal passes through the material. A lower Df value indicates better signal integrity and lower power loss.

| Material | Dissipation Factor (Df) |

|---|---|

| FR-4 | 0.02 – 0.03 |

| RO4003C | 0.0027 |

| RO4350B | 0.0037 |

| RT/duroid 5870 | 0.0012 |

| Polyimide | 0.002 – 0.003 |

Thermal Conductivity

Thermal conductivity is a measure of a material’s ability to conduct heat. Higher thermal conductivity allows for better heat dissipation, which is essential for high-power applications and increased reliability.

| Material | Thermal Conductivity (W/mK) |

|---|---|

| FR-4 | 0.3 – 0.4 |

| RO4003C | 0.64 |

| RO4350B | 0.62 |

| RT/duroid 5870 | 0.22 |

| Polyimide | 0.1 – 0.2 |

Applications of PCB Materials

High-Frequency Applications

For high-frequency applications, such as RF and microwave circuits, low-loss materials like Rogers materials are preferred. These materials offer stable dielectric constants and low dissipation factors, minimizing signal loss and ensuring optimal performance.

High-Temperature Applications

In high-temperature environments, materials with excellent thermal stability, such as polyimide, are essential. These materials can withstand elevated temperatures without degrading or losing their mechanical and electrical properties.

Flexible Electronics

Flexible PCB materials, such as polyimide and polyester, are used in applications that require conformability, lightweight design, and improved shock and vibration resistance. Examples include wearable devices, medical implants, and aerospace electronics.

PCB Material Selection Considerations

When selecting PCB materials, several factors should be considered:

-

Electrical requirements: Consider the dielectric constant, dissipation factor, and signal integrity requirements of the application.

-

Thermal requirements: Evaluate the thermal conductivity and thermal stability needed for the specific operating environment.

-

Mechanical requirements: Assess the mechanical strength, flexibility, and durability required for the application.

-

Cost: Determine the budget constraints and cost-performance trade-offs for the project.

-

Manufacturability: Consider the ease of fabrication and processing for the chosen material, as some materials may require specialized equipment or techniques.

Frequently Asked Questions (FAQ)

1. What is the most common PCB material?

FR-4 is the most widely used PCB material due to its good balance of mechanical, electrical, and thermal properties, as well as its cost-effectiveness.

2. What PCB materials are best for high-frequency applications?

Rogers materials, such as RO4003C, RO4350B, and RT/duroid 5870, are preferred for high-frequency applications due to their low dielectric loss and stable dielectric constant.

3. Can flexible PCB materials be used for high-temperature applications?

Some flexible PCB materials, such as polyimide, offer excellent thermal stability and can be used in high-temperature applications. However, it is essential to consider the specific temperature requirements and consult with the manufacturer for guidance.

4. How does the dielectric constant affect PCB Performance?

A lower dielectric constant (Dk) is generally preferred for high-frequency applications, as it minimizes signal loss and improves signal integrity. Materials with lower Dk values allow for faster signal propagation and reduced crosstalk.

5. Are there any environmental concerns when selecting PCB materials?

Yes, environmental considerations, such as RoHS Compliance and halogen-free requirements, should be taken into account when selecting PCB materials. Some materials may contain hazardous substances that are restricted or prohibited by environmental regulations.

Conclusion

Selecting the appropriate PCB material is crucial for ensuring the optimal performance, reliability, and cost-effectiveness of electronic devices. By understanding the properties, advantages, and disadvantages of various PCB materials, designers and engineers can make informed decisions based on the specific requirements of their applications. From high-frequency circuits to high-temperature environments and flexible electronics, the right choice of PCB material can significantly impact the success of a project.

Leave a Reply