Introduction to PCB Components

Printed Circuit Boards (PCBs) are the foundation of modern electronics. They provide a platform for mounting and interconnecting various electronic components to create functional circuits. PCBs consist of a non-conductive substrate, typically made of fiberglass or plastic, with conductive copper traces etched onto the surface to form the desired circuit pattern. The components are then soldered onto the board to complete the circuit.

PCBs are used in a wide range of applications, from simple single-layer boards for basic electronics projects to complex multi-layer boards for advanced industrial and medical devices. The components used on PCBs can vary greatly depending on the specific application and design requirements. However, there are several common components that are found on most PCBs.

Types of PCB Components

1. Resistors

Resistors are one of the most basic and commonly used components on PCBs. They are passive two-terminal devices that resist the flow of electrical current. Resistors are used to control the voltage and current in a circuit, as well as to provide a specific resistance value for various applications.

Resistors come in different types, including:

- Fixed Resistors: These have a fixed resistance value that cannot be changed.

- Variable Resistors: Also known as potentiometers, these allow the resistance value to be adjusted.

- Surface Mount Resistors (SMD): These are smaller in size and are mounted directly onto the PCB surface.

The resistance value of a resistor is measured in ohms (Ω) and is typically indicated by a color code or printed value on the component body.

Resistor Applications:

- Voltage division

- Current limiting

- Pull-up and pull-down resistors

- Termination resistors

- Heating elements

2. Capacitors

Capacitors are another essential component found on most PCBs. They are passive two-terminal devices that store electrical energy in an electric field. Capacitors are used for a variety of purposes, such as filtering, coupling, decoupling, and energy storage.

Capacitors come in different types, including:

- Ceramic Capacitors: These are the most common type and are available in various sizes and capacitance values.

- Electrolytic Capacitors: These have a higher capacitance value and are polarized, meaning they have a positive and negative terminal.

- Tantalum Capacitors: These are similar to electrolytic capacitors but offer better stability and reliability.

- Film Capacitors: These are known for their high precision and low noise characteristics.

The capacitance value of a capacitor is measured in farads (F) and is often expressed in microfarads (μF) or picofarads (pF).

Capacitor Applications:

- Power supply filtering

- Signal coupling and decoupling

- Timing circuits

- Resonant circuits

- Energy storage

3. Inductors

Inductors are passive two-terminal devices that store energy in a magnetic field when an electric current flows through them. They are used for various purposes, such as filtering, energy storage, and impedance matching.

Inductors come in different types, including:

- Air Core Inductors: These have no core material and are typically used at high frequencies.

- Ferrite Core Inductors: These have a ferrite core material that increases the inductance value and improves performance.

- Toroidal Inductors: These have a donut-shaped core and offer excellent magnetic shielding properties.

The inductance value of an inductor is measured in henries (H) and is often expressed in microhenries (μH) or nanohenries (nH).

Inductor Applications:

- Power supply filtering

- RF and EMI suppression

- Impedance matching

- Energy storage

- DC-DC converters

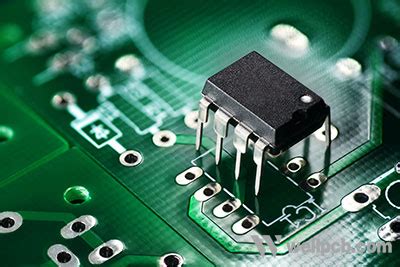

4. Integrated Circuits (ICs)

Integrated Circuits, or ICs, are miniaturized electronic circuits that are fabricated on a single semiconductor substrate, typically silicon. ICs contain a large number of transistors, diodes, resistors, and capacitors that are interconnected to perform a specific function. They are essential components in modern electronics and are used in a wide range of applications.

ICs come in different types, including:

- Microcontrollers: These are programmable ICs that contain a processor, memory, and input/output peripherals.

- Amplifiers: These are used to increase the amplitude of a signal.

- Voltage Regulators: These are used to maintain a constant voltage level in a circuit.

- Sensors: These are used to measure various physical quantities, such as temperature, pressure, or light.

ICs are available in different package types, such as Dual Inline Package (DIP), Small Outline Integrated Circuit (SOIC), and Quad Flat Package (QFP).

IC Applications:

- Signal processing

- Power management

- Microcontrollers and microprocessors

- Sensors and transducers

- Communication interfaces

5. Diodes

Diodes are two-terminal semiconductor devices that allow current to flow in only one direction, from the anode to the cathode. They are used for various purposes, such as rectification, protection, and switching.

Diodes come in different types, including:

- Rectifier Diodes: These are used to convert alternating current (AC) to direct current (DC).

- Zener Diodes: These are used for voltage regulation and protection against overvoltage.

- Schottky Diodes: These have a lower forward voltage drop and are used for high-speed switching applications.

- Light Emitting Diodes (LEDs): These emit light when a current flows through them and are used for indication and lighting purposes.

Diode Applications:

- Power supply rectification

- Overvoltage Protection

- Reverse polarity protection

- High-speed switching

- LED indicators and lighting

6. Transistors

Transistors are three-terminal semiconductor devices that are used for amplification and switching of electronic signals. They are the building blocks of modern electronics and are found in almost every electronic device.

Transistors come in two main types:

- Bipolar Junction Transistors (BJTs): These are current-controlled devices that have three regions: emitter, base, and collector.

- Field Effect Transistors (FETs): These are voltage-controlled devices that have three terminals: gate, source, and drain. MOSFETs (Metal Oxide Semiconductor Field Effect Transistors) are the most common type of FETs.

Transistors are available in different package types, such as TO-92, SOT-23, and SMD packages.

Transistor Applications:

- Signal amplification

- Switching circuits

- Power regulation

- Logic gates

- Voltage and current control

7. Connectors

Connectors are used to establish electrical and mechanical connections between different parts of a circuit or between a PCB and external devices. They provide a means for transferring power, signals, and data between various components.

Connectors come in different types, including:

- Header Connectors: These are male connectors that consist of a row of pins.

- Socket Connectors: These are female connectors that mate with header connectors.

- Edge Connectors: These are used to connect PCBs to other boards or devices.

- Screw Terminals: These provide a secure connection for wires or cables.

- USB Connectors: These are used for connecting USB devices to a PCB.

Connector Applications:

- Board-to-board connections

- Wire-to-Board connections

- Power supply connections

- Signal and data transmission

- Modular device interconnections

PCB Component Selection Considerations

When selecting components for a PCB, several factors need to be considered to ensure optimal performance, reliability, and cost-effectiveness. Some of the key considerations include:

- Electrical Specifications:

- Voltage and current ratings

- Power dissipation

- Frequency response

-

Tolerance and accuracy

-

Environmental Factors:

- Operating temperature range

- Humidity and moisture resistance

- Vibration and shock resistance

-

Altitude and pressure

-

Physical Characteristics:

- Package type and size

- Mounting style (through-hole or surface mount)

- Thermal management

-

Mechanical strength and durability

-

Reliability and Quality:

- Component manufacturer reputation

- Certifications and compliances

- Failure rates and lifespan

-

Traceability and documentation

-

Cost and Availability:

- Component price and quantity discounts

- Lead times and minimum order quantities

- Alternative sources and substitutions

- Inventory management and obsolescence risk

By carefully considering these factors and selecting appropriate components, designers can create PCBs that meet the specific requirements of their applications while optimizing performance, reliability, and cost.

PCB Component Placement and Layout

Proper placement and layout of components on a PCB are crucial for ensuring optimal electrical performance, signal integrity, and manufacturability. Some key guidelines for PCB component placement and layout include:

- Functional Grouping:

- Place components with similar functions or subcircuits together.

-

Minimize the distance between related components to reduce signal propagation delays and noise.

-

Power Supply Decoupling:

- Place decoupling capacitors close to the power pins of ICs to minimize power supply noise and improve signal integrity.

-

Use appropriate capacitor values and placement techniques based on the frequency and current requirements.

-

Signal Routing:

- Route high-speed signals using controlled impedance techniques to maintain signal integrity.

-

Avoid sharp bends, long parallel runs, and crossing of sensitive signals to minimize crosstalk and interference.

-

Thermal Management:

- Place temperature-sensitive components away from heat-generating components.

- Provide adequate spacing and copper pours for heat dissipation.

-

Consider the use of thermal vias and heatsinks for high-power components.

-

Manufacturing Considerations:

- Adhere to the minimum spacing and clearance requirements specified by the PCB manufacturer.

- Place components in a way that facilitates automated assembly and inspection processes.

- Consider the orientation and placement of components for ease of soldering and rework.

By following these guidelines and using appropriate PCB design software tools, designers can create PCBs with optimal component placement and layout, leading to improved performance, reliability, and manufacturability.

Frequently Asked Questions (FAQ)

- What is the difference between through-hole and surface mount components?

-

Through-hole components have long leads that are inserted into holes drilled in the PCB and soldered on the opposite side. Surface mount components are smaller and are soldered directly onto the surface of the PCB without requiring holes. Surface mount technology allows for higher component density and faster assembly processes.

-

How do I identify the value of a resistor or capacitor?

-

Resistors typically use a color code system or have their resistance value printed directly on the component body. Each color band represents a specific digit or multiplier. Capacitors often have their capacitance value and tolerance printed on the component body using a numerical code or a combination of numbers and letters.

-

What is the purpose of decoupling capacitors?

-

Decoupling capacitors are used to minimize power supply noise and improve signal integrity. They are placed close to the power pins of ICs to provide a local source of charge and filter out high-frequency noise. Decoupling capacitors help to stabilize the power supply voltage and prevent signal distortion.

-

How do I choose the appropriate package type for a component?

-

The choice of package type depends on various factors, including the PCB design constraints, component availability, assembly process, and environmental requirements. Through-hole packages are generally larger and easier to solder manually, while surface mount packages offer higher density and automated assembly capabilities. Consider the size, pitch, and thermal requirements when selecting a package type.

-

What are the common causes of component failure on PCBs?

- Component failure on PCBs can occur due to various reasons, including:

- Overheating or thermal stress

- Electrostatic discharge (ESD) events

- Overvoltage or overcurrent conditions

- Mechanical stress or vibration

- Manufacturing defects or poor soldering

- Component aging or wear-out

To minimize component failure, it is important to follow proper design guidelines, use appropriate protection circuits, and adhere to recommended handling and assembly procedures.

Conclusion

PCBs are the backbone of modern electronics, and the components used on them play a crucial role in determining the functionality, performance, and reliability of electronic devices. Understanding the commonly used PCB components, their characteristics, and their applications is essential for designing and manufacturing successful electronic products.

From basic passive components like resistors and capacitors to more complex ICs and connectors, each component serves a specific purpose in the overall circuit. Proper selection, placement, and layout of these components are critical for achieving optimal electrical performance, signal integrity, and manufacturability.

By considering factors such as electrical specifications, environmental conditions, physical characteristics, reliability, and cost, designers can make informed decisions when choosing components for their PCB designs. Following best practices for component placement and layout, such as functional grouping, power supply decoupling, signal routing, and thermal management, further enhances the performance and reliability of the PCB.

As technology continues to advance and new components are introduced, staying up-to-date with the latest industry trends and best practices is essential for designers and manufacturers. By understanding the fundamentals of PCB components and their applications, electronics professionals can create innovative and reliable products that meet the ever-increasing demands of the modern world.

Leave a Reply