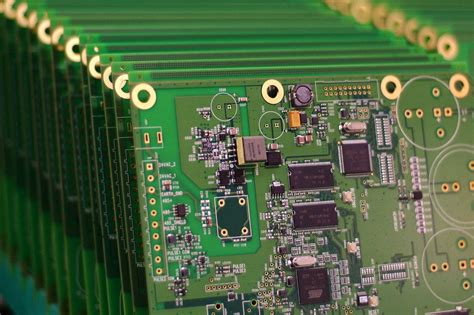

What is PCB Assembly?

PCB assembly is the process of attaching electronic components to a printed circuit board. The process involves several steps, including:

-

Solder Paste Application: A thin layer of solder paste is applied to the PCB’s contact pads using a stencil or screen printing process.

-

Component Placement: The electronic components are precisely placed onto the PCB using automated pick-and-place machines or manual placement for smaller batches.

-

Reflow Soldering: The PCB is heated in a reflow oven, causing the solder paste to melt and form a permanent connection between the components and the PCB.

-

Inspection and Testing: The assembled PCB undergoes visual inspection and electrical testing to ensure proper functionality and adherence to quality standards.

PCB assembly can be categorized into two main types:

-

Surface Mount Technology (SMT) Assembly: SMT involves placing components directly onto the surface of the PCB. This method allows for smaller component sizes and higher component density, resulting in more compact PCBs.

-

Through-Hole Technology (THT) Assembly: THT involves inserting component leads through holes drilled in the PCB and soldering them on the opposite side. This method is often used for larger components or when mechanical strength is a priority.

What are the Benefits of Outsourcing PCB Assembly?

Outsourcing PCB assembly to a specialized service provider offers several benefits, including:

-

Cost Savings: Outsourcing eliminates the need for investing in expensive assembly equipment, facilities, and skilled labor, reducing overall production costs.

-

Expertise and Quality: PCB assembly service providers have the necessary expertise, equipment, and processes in place to ensure high-quality assembly and adherence to industry standards.

-

Faster Turnaround Times: With dedicated resources and streamlined processes, PCB assembly service providers can often deliver assembled PCBs faster than in-house assembly.

-

Scalability: Outsourcing allows you to easily scale production up or down based on demand, without the need to manage additional resources or capacity.

-

Access to Advanced Technologies: PCB assembly service providers often invest in the latest assembly technologies and processes, ensuring access to state-of-the-art capabilities.

How to Choose the Right PCB Assembly Service Provider?

When selecting a PCB assembly service provider, consider the following factors:

-

Experience and Expertise: Look for a provider with a proven track record in PCB assembly and experience in your specific industry or application.

-

Quality Standards: Ensure that the provider adheres to relevant quality standards, such as IPC (Association Connecting Electronics Industries) standards, and has a robust quality management system in place.

-

Capabilities and Technology: Assess the provider’s assembly capabilities, including SMT and THT assembly, component placement accuracy, and the ability to handle complex designs or specialized components.

-

Turnaround Time and Flexibility: Consider the provider’s typical turnaround times and their ability to accommodate your specific needs, such as rush orders or design changes.

-

Communication and Support: Evaluate the provider’s communication channels, responsiveness, and level of technical support to ensure a smooth collaboration.

-

Cost and Value: While cost is an important factor, also consider the overall value provided, including quality, reliability, and additional services such as design support or supply chain management.

What Information Should You Provide for a PCB Assembly Quote?

To receive an accurate PCB assembly quote, provide the following information to your service provider:

-

Bill of Materials (BOM): A comprehensive list of all components required for the assembly, including part numbers, quantities, and any special instructions.

-

Gerber Files: The complete set of Gerber files for your PCB Design, including the copper layers, solder mask, silkscreen, and drill files.

-

Assembly Drawings: Detailed assembly drawings or instructions, specifying component placement, orientation, and any special requirements.

-

Quantity and Turnaround Time: The number of PCBs you need to be assembled and your desired turnaround time.

-

Any Additional Requirements: Specify any special requirements, such as conformal coating, testing, or packaging needs.

What are the Common PCB Assembly Defects and How to Prevent Them?

Common PCB assembly defects include:

-

Solder Bridges: Unintended connections between two or more solder joints, causing short circuits. Prevention: Proper solder paste application, accurate component placement, and controlled reflow soldering process.

-

Cold Solder Joints: Weak or unstable solder connections due to insufficient heat during the soldering process. Prevention: Ensure proper reflow temperature profile and maintain equipment calibration.

-

Component Misalignment: Misplaced or rotated components, leading to improper connections or mechanical issues. Prevention: Use accurate pick-and-place machines and implement quality control checks.

-

Tombstoning: When a component stands up on one end due to uneven heating or surface tension during reflow soldering. Prevention: Ensure balanced solder paste application and proper component placement.

-

Insufficient Solder: Lack of solder, resulting in weak or open connections. Prevention: Use appropriate solder paste stencil thickness and maintain proper solder paste viscosity.

To prevent these defects, work with an experienced PCB assembly service provider that follows industry best practices, maintains strict quality control measures, and uses advanced assembly equipment and processes.

How Long Does PCB Assembly Typically Take?

The turnaround time for PCB assembly depends on various factors, including:

-

Design Complexity: More complex designs with a higher number of components or advanced features may require longer assembly times.

-

Quantity: Larger order quantities may take longer to assemble, but may also benefit from economies of scale.

-

Component Availability: The availability of required components can impact the overall assembly timeline, especially for specialized or hard-to-find components.

-

Service Provider Capacity: The PCB assembly service provider’s current workload and capacity can affect turnaround times.

Typical turnaround times for PCB assembly can range from a few days to several weeks, depending on the above factors. Rush services may be available for time-sensitive projects, but may incur additional costs. To ensure the best possible turnaround time, provide complete and accurate information to your service provider and maintain clear communication throughout the assembly process.

What are the Environmental Considerations in PCB Assembly?

PCB assembly involves the use of various chemicals and materials that can have environmental impacts. Responsible PCB assembly service providers prioritize environmental considerations and adopt sustainable practices, such as:

-

Lead-Free Soldering: Using lead-free solder alloys to reduce the environmental and health risks associated with lead exposure.

-

RoHS Compliance: Adhering to the Restriction of Hazardous Substances (RoHS) directive, which restricts the use of certain hazardous materials in electronic products.

-

Proper Waste Management: Implementing proper waste management practices, including the safe disposal of chemicals, solder waste, and other byproducts of the assembly process.

-

Energy Efficiency: Adopting energy-efficient equipment and processes to reduce the environmental footprint of PCB assembly operations.

-

Sustainable Packaging: Using eco-friendly packaging materials and minimizing packaging waste where possible.

When choosing a PCB assembly service provider, inquire about their environmental policies and practices to ensure they align with your organization’s sustainability goals and values.

Frequently Asked Questions (FAQ)

-

Q: What is the minimum order quantity (MOQ) for PCB assembly services?

A: The minimum order quantity for PCB assembly services varies by provider. Some providers specialize in low-volume production and may have MOQs as low as one piece, while others may require higher minimum quantities for cost-effective assembly. Discuss your specific needs with potential service providers to find the best fit for your project. -

Q: Can PCB assembly service providers source components on my behalf?

A: Yes, many PCB assembly service providers offer Component sourcing services. They can procure components based on your bill of materials (BOM) and ensure the availability and compatibility of the components for your assembly project. This service can help streamline your supply chain and reduce the risk of component-related delays. -

Q: What quality certifications should I look for in a PCB assembly service provider?

A: Look for PCB assembly service providers that hold relevant quality certifications, such as ISO 9001 (Quality Management Systems), IPC-A-610 (Acceptability of Electronic Assemblies), and J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies). These certifications demonstrate the provider’s commitment to quality and adherence to industry standards. -

Q: Can PCB assembly service providers handle both prototype and high-volume production?

A: Many PCB assembly service providers offer services for both prototype and high-volume production. However, some providers may specialize in one or the other. When selecting a provider, ensure that they have the capabilities and experience to handle your specific production requirements, whether it’s low-volume prototyping or large-scale manufacturing. -

Q: What are the shipping and packaging options for assembled PCBs?

A: PCB assembly service providers typically offer various shipping and packaging options to meet your needs. This can include standard or expedited shipping, as well as specialized packaging for delicate or moisture-sensitive components. Discuss your shipping and packaging requirements with your service provider to ensure your assembled PCBs are delivered safely and efficiently.

In conclusion, PCB assembly services play a vital role in the production of electronic devices. By understanding the answers to these frequently asked questions, you can make informed decisions when selecting a PCB assembly service provider and ensure a successful collaboration for your projects.

Leave a Reply