Introduction to PCB Manufacturing in China

Printed circuit boards (PCBs) form the backbone of all electronic devices and equipment. From smartphones and laptops to industrial control systems and medical devices, PCBs provide the foundation on which components are mounted and inter-connected.

Over the past few decades, PCB manufacturing has largely shifted from North America and Europe to Asia, especially China. Currently, China produces over 50% of the world’s PCBs and is home to some of the largest PCB manufacturers on the planet. The reasons for this shift include:

- Lower Manufacturing Costs: Labor, raw materials, facilities, and energy are considerably cheaper in China compared to other regions. This allows Chinese factories to manufacture PCBs at a fraction of the cost.

- Economies of Scale: The concentration of PCB suppliers in China has led to economies of scale, further driving down costs. Chinese factories can spread fixed costs over a high production volume.

- State-of-the-Art Facilities: Backed by government support and private investment, Chinese PCB manufacturers employ cutting-edge fabrication equipment and processes. They can match the quality of top PCB makers globally.

- Broad Production Capabilities: Chinese PCB companies offer a comprehensive range of services from prototype runs to high-volume manufacturing. They can cater to requirements across industry sectors.

For these reasons, China has become the go-to destination for sourcing printed circuit boards. In this guide, we will walk through the key steps involved in ordering PCBs from China.

How to Select a Suitable PCB Manufacturer in China

With thousands of PCB manufacturers in China, selecting the right partner can seem daunting initially. Here are some tips on identifying reputable PCB makers in China:

- Search company directories: Industry portals like www.pcb007.com maintain directories of Chinese PCB manufacturers classified by capabilities and specializations. These are good starting points for research.

- Check online reviews: Sourcing websites like Alibaba have reviews from past customers of PCB suppliers. Read reviews carefully to gauge customer satisfaction levels.

- Evaluate company credentials: Look for certifications like ISO-9001 and UL to confirm that the PCB company follows rigorous quality processes.

- Assess production capabilities: Confirm that the PCB maker offers the technology (e.g. HDI PCB) and volumes (e.g. 10,000+ boards/month) you need.

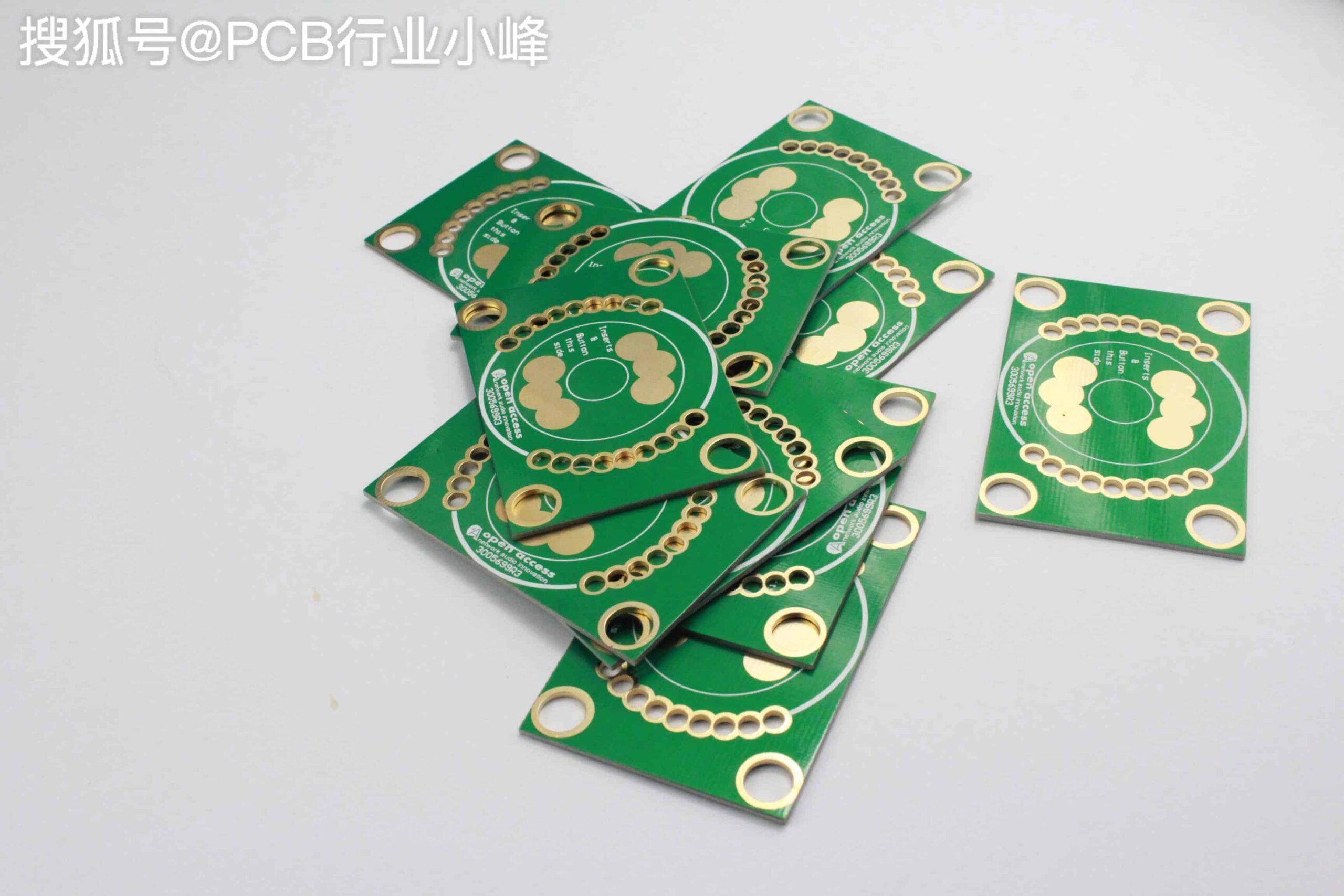

- Request product samples: Ask PCB suppliers to share samples of boards they have produced in the past. Physically examine the samples for quality.

- Compare pricing: Get quotes from multiple PCB manufacturers in China for your requirements to find the best deal. Be wary of prices that seem too good to be true.

Major PCB Manufacturing Clusters in China

PCB production in China is concentrated in three major regions:

Shenzhen

The Shenzhen region produces over 50% of Chinese PCB output. Key advantages are:

- Proximity to Hong Kong makes it easy to export PCBs globally

- Presence of electronics ecosystem with component suppliers and product manufacturers

- Government incentives for tech manufacturing

Major PCB companies in Shenzhen include All PCB, Maeco Circuits, and PCBWay.

Shanghai

Shanghai accounts for around 20% of Chinese PCB production. It offers these benefits:

- Highly skilled engineering talent pool

- Excellent port infrastructure reduces shipping times

- Favorable government policies within special economic zones

Top PCB manufacturers in Shanghai are Topscom, Ray PCB, and RYlec.

Jiangsu & Zhejiang

The Yangtze River Delta is home to around 15% of Chinese PCB output. Advantages are:

- Proximity to raw material suppliers of laminate, prepreg, copper

- Tax incentives for manufacturers in the region

- Availability of advanced production equipment

Well-known PCB makers here include Founder Technology and Zhongding Technology.

Factors to Consider When Choosing a Chinese PCB Partner

Here are some key parameters to evaluate when shortlisting Chinese PCB suppliers:

Type of PCB Required

- Rigid PCBs: Used in majority of electronics and relatively straightforward to manufacture. A good choice if this is your first Chinese PCB order.

- Flexible PCBs: Used where bending or conformity to shape is needed. Require specialized materials and processes.

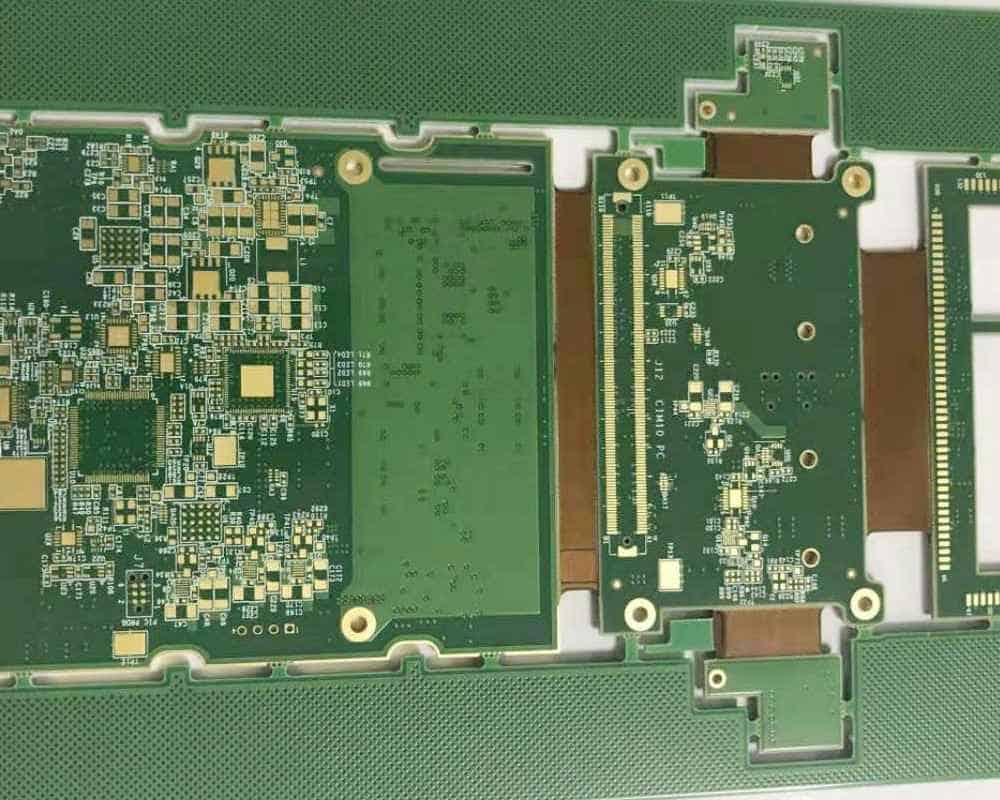

- Rigid-Flex PCBs: Combine both rigid and flexible circuitry. More complex to fabricate.

- HDI PCBs: Have fine traces and spaces. Need advanced lithography equipment. Used in compact devices.

- High Frequency PCBs: Have controlled impedance and material properties. Used in RF and microwave circuits.

- Metal Core PCBs: Have metal substrate to conduct heat. Used in LEDs and power electronics.

Match PCB type to manufacturer’s capabilities.

Production Volumes Needed

- Prototype: 10-50 boards to evaluate design. Offered by most manufacturers.

- Small Volume: 100-1,000 boards for testing or pilot builds. Check minimum order quantities.

- Medium Volume: 1,000-10,000 boards for initial product run. Optimal for balanced pricing.

- High Volume: 10,000+ boards for established products. Get quotes from multiple big suppliers.

Choose partner aligned with your scale of production.

PCB Specifications

- Layers: Number of conductive layers in PCB stackup. More layers allow higher component density but increase fabrication difficulty.

- Board Size: Some Chinese PCB makers specialize in small boards e.g. for smartphones while others cater to large panels used in TVs.

- Board Thickness: Standard 1.6mm. Thicker 2.4mm boards provide more stiffness. Thinner 1.0mm boards used in space-constrained devices.

- Precise Impedance Control: Needed for match-critical circuits like DDR channels. Not all suppliers can guarantee tight tolerances.

- High Aspect Ratio: For PCBs with fine features and lines/spaces below 100/100um. Requires advanced processes.

Pick a PCB maker capable of meeting your board’s parameters.

Quality and Reliability

- Testing: What electrical, mechanical and environmental tests are performed? Are engineers available to analyze test results?

- Certifications: Look for ISO, IATF 16949, UL, etc. to indicate rigorous quality processes are in place.

- Traceability: Can PCB supplier track each board to the specific production batch and fabrication processes used to produce it?

- Documentation: Are comprehensive data packs with test reports, certificates of compliance, etc. provided?

Assess the supplier’s commitments to quality and process control.

Customer Support

- Technical Assistance: Are engineers available during PCB design stage to review manufacturability, make recommendations, and address queries?

- Communication: Does the supplier have English-speaking staff for smooth exchange of information? How responsive are they via email, phone, chat?

- NPI Assistance: For new product introduction, does the supplier offer design review, prototyping, pre-production builds, etc. to help you get to market faster?

- Logistics Support: Does the PCB company handle customs clearance, shipping documentation, component procurement, etc. on your behalf?

Evaluate ease of engagement with the supplier during design and manufacturing.

PCB Design Considerations for Manufacturing in China

Adhering to design guidelines and fabrication capabilities of your chosen Chinese PCB manufacturer ensures your board can be produced without issues and meets reliability expectations. Here are some aspects to keep in mind:

Component Selection

- Preferred component packages: Optimize design for surface-mount devices which are easier to assemble vs. through-hole parts.

- Component sourcing: Supplier can source common passive components, connectors etc. locally in China at low cost. But rare or obsolete parts may need to be supplied by you.

- BOM optimization: Consolidate to the fewest unique component values, ratings and packages to streamline procurement and assembly.

Board Layout

- Panel utilization: Optimize board outline and rotation on panel to maximize manufacturing panel utilization and minimize waste.

- Stackup: Standard 4-layer or 6-layer builds are cost-effective. Extra layers add cost.

- High speed routing: Length-match critical nets, configure return paths, enable impedance control. Seek manufacturer advice.

- Planar dimensions: Maintain clearance between copper features as per capabilities of PCB supplier’s equipment and processes.

- Finish requirements: Specify surface finish like Immersion Gold, ENIG or OSP carefully based on application needs.

- Solder mask: Use manufacturer-recommended mask color, curing method, thickness and tolerances.

- Silkscreen: Use laser-cut or inkjet printed legend depending on volume. White background provides maximum contrast.

- Tooling holes: Add tooling holes outside board profile for accurate alignment during fabrication.

Documentation

- Gerber files: Ensure PCB design software outputs Gerber and drill files compatible with Chinese manufacturer’s CAM system.

- Bill of Materials (BOM): Submit complete BOM specifying manufacturer part numbers, description, reference designators and quantity needed.

- Assembly Drawings: Provide detailed solder paste stencil drawings, 2D assembly diagrams and a 3D model to aid assembly programming.

- Fabrication notes: Include any special instructions on layer stacking, material requirements, controlled impedance regions, etc.

Thorough documentation prevents miscommunication and ensures product realization.

Chinese PCB Assembly Options

Most PCB suppliers in China also offer assembly services or partner with assembly houses. Typical assembly options are:

Full Turnkey Assembly

The PCB manufacturer procures components, programs the assembly line, and assembles your populated boards ready for testing. This is the simplest option but may not be the most cost-effective.

Consigned Components

You supply component kits to the manufacturer who has prepared SMT programs, solder paste stencils, etc. They then assemble the boards using your supplied components. Saves cost of having PCB vendor buy components.

Customer Supplied SMT Programs

You provide detailed SMT machine programming files optimized for your specific component placement. The PCB assembler loads these programs and assembles boards using your component kits. Gives you maximum control.

Board Level Assembly

Only SMT components are assembled by the supplier. You perform manual placement and soldering of through-hole parts, connectors, cables etc. afterwards. Lowest cost option.

Box Build Assembly

Assembled PCBs are integrated with enclosures, cables, displays and other hardware to complete full product assembly. Highest level of value-add.

Choose the assembly option balancing control, cost and convenience for your needs.

How to Verify Quality of Assembled PCBs

To confirm assembled PCBs meet specifications, the following tests and inspections should be performed:

Tests

- Visual Inspection: Check for defects in solder, components and board damage.

- In-Circuit Testing: Verify electrical continuity of traces, vias and proper joining of components.

- Functional Testing: Validate circuit operation and performance meets requirements.

- Environmental Stress Testing: Assess reliability under temperature, vibration, etc.

Inspections

- Solder Paste Inspection: Detect printing flaws like insufficient paste or smearing.

- Solder Joint Inspection: Check for good fillet formation, no shorts, missing joints etc.

- AOI Inspection: Use automated optical inspection to find assembly defects.

- X-Ray Inspection: Reveal issues like solder voiding within BGA/QFN packages.

Metrics

- First Pass Yield: Percentage of boards passing inspection versus total assembled. Aim for >=95%.

- Defects per Million Opportunities (DPMO): Number of defects found per assembly steps performed. Target <=100 DPMO.

- Test Coverage: Extent of testing performed versus planned. Goal of >=95% coverage.

Analyzing test results against these metrics indicates quality level achieved.

Helpful Tips for Your First Chinese PCB Order

If sourcing PCBs from China for the first time, keep the following tips in mind:

- Don’t compromise too much on price at the cost of quality. Set clear expectations upfront.

- Build proper tolerances for board dimensions, hole sizes etc. into your design to accommodate process variations.

- Engage the PCB supplier early in design stage and keep them updated as design evolves.

- Document everything comprehensively – your statement of work, BOM, Gerbers, test requirements etc. Avoid assumptions.

- Perform design and/or process reviews with your supplier at key milestones.

- Plan for extra time in schedules just in case unexpected issues arise.

- Once you finalize a manufacturing partner, consider a long-term relationship to benefit from their learning over time.

- Be ready to pay a little extra for pre-production prototypes ordered in small quantities.

Following these pointers will help you get your first Chinese PCB order delivered on time and within budget.

Frequently Asked Questions

Q: What are the shipping options when ordering PCBs from China?

A: Most Chinese PCB manufacturers offer international shipping via air or sea:

- Air shipping is faster (5-7 days) but more expensive

- Sea shipping takes 2-3 weeks but costs much lower

- Many factories offer DHL, UPS, Fedex, TNT for air shipping

- Sea shipping is usually through EMS, DHL Global Mail, FedEx IE/IP

- Door-to-door delivery options may also be available

- Ask suppliers for full details on shipping time and costs to your location

Q: What payment options are available for buying PCBs from China?

A: Common payment modes when ordering PCBs from China include:

- T/T Wire Transfer – Most preferred option for Chinese suppliers

- PayPal – Convenient online payment, may have transaction fees

- Alibaba Trade Assurance – Hold payment in escrow until you receive order

- Western Union – Quick transfer but usually has higher fees

- Letter of Credit – Payment made after shipment inspection, through banks

- AliPay, WeChat Pay – Useful for small payments within China

- Credit Cards – Relatively rare due to high fees for suppliers

Agree beforehand with supplier on suitable payment option.

Q: How can I protect my intellectual property when working with a Chinese PCB supplier?

A: Some ways to protect your IP when sourcing PCBs from China:

- Sign an NDA with your supplier to protect confidential design information

- Remove or conceal any sensitive identifiers, logos etc. in design files shared

- Use encrypted file transfer portals for exchanging design documents

- Ask suppliers about security policies governing access to customer data

- Split manufacturing between multiple suppliers so no one has complete info

- Register copyrights and trademarks to strengthen legal standing

- Limit where possible which supplier teams can view your full data

- Make periodic site visits to audit supplier security and confidentiality measures

Q: What certifications should a good PCB manufacturer have?

A: Some key certifications to look for in Chinese PCB suppliers:

- ISO 9001 – Confirms quality management system process focus

- ISO 14001 – Indicates environment management practices employed

- IATF 16949 – Automotive quality system requirements signifying high capability

- ISO 13485 – Meets rigorous standards for medical devices

- AS 9100 – Aerospace quality management benchmarks

- TL 9000 – Telecom quality system for high reliability

- UL – Product safety certification for PCB flammability

- IPC Certifications – Training standards across PCB fabrication, assembly and testing

These certifications validate the manufacturer adheres to best practices.

Q: What are some red flags to watch out for when selecting a Chinese PCB supplier?

Some potential red flags when evaluating Chinese PCB manufacturers:

- Extremely low prices much below market rates

- Lack of customer reviews and track record

- Unwillingness to share examples of previous work

- Lack of quality certifications from 3rd parties

- Poor responsiveness to customer inquiries and issues

- Unclear or confusing business processes and documentation

- Inability to deal with English-speaking contacts

- Lack of security provisions for intellectual property

- Hidden costs that are revealed after design/order is placed

While price is important, extremely low bids likely indicate quality shortcuts or potential risks. Carefully vet suppliers for proven capability, responsiveness and transparency.

Leave a Reply