1. Health and Safety Concerns

Exposure to Hazardous Chemicals

One of the primary reasons we discourage home PCB Etching is the potential health risks associated with the chemicals used in the process. Etching solutions typically contain strong acids or alkaline substances that can cause severe burns, respiratory issues, and other health problems if not handled properly.

Some common chemicals used in PCB etching include:

| Chemical | Hazards |

|---|---|

| Ferric Chloride | Corrosive, can cause skin and eye damage |

| Hydrochloric Acid | Highly corrosive, can cause burns and respiratory issues |

| Sodium Persulfate | Irritant, can cause skin and eye irritation |

Inadequate Safety Equipment

In a professional setting, PCB etching is conducted in well-ventilated areas with proper safety equipment such as fume hoods, protective clothing, and eye protection. Most homes lack these essential safety measures, increasing the risk of exposure to harmful chemicals and fumes.

2. Environmental Impact

Improper Disposal of Chemicals

Another significant concern with home PCB etching is the potential environmental impact. Etching solutions and rinse water containing dissolved copper and other chemicals should never be poured down the drain or disposed of in regular trash. Improper disposal can lead to contamination of water sources and harm to aquatic life.

Lack of Proper Waste Management

Professional PCB manufacturers have strict protocols in place for the proper disposal and treatment of hazardous waste generated during the etching process. Homeowners often lack the knowledge and resources to handle these wastes responsibly, leading to potential environmental damage.

3. Inconsistent Results

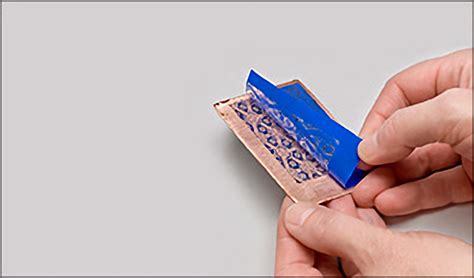

Difficulty in Controlling Etching Parameters

Achieving consistent and high-quality results in PCB etching requires precise control over various parameters such as temperature, agitation, and etch time. Without proper equipment and expertise, it can be challenging to maintain these parameters, leading to inconsistent etching and poor-quality boards.

Increased Risk of Over-Etching or Under-Etching

Home etching setups often lack the precision and monitoring capabilities of professional equipment. This increases the risk of over-etching, which can lead to broken traces and damaged components, or under-etching, resulting in unwanted copper remaining on the board.

4. Limited Design Capabilities

Restricted Feature Sizes

Professional PCB manufacturers use advanced techniques and equipment to create high-density boards with fine features and narrow trace widths. Home etching methods are typically limited in their ability to produce such intricate designs, restricting the complexity and functionality of the resulting PCBs.

Difficulty in Creating Multi-Layer Boards

Multi-layer PCBs, which are essential for many modern electronic devices, are extremely challenging to produce using home etching methods. The precise alignment and lamination required for multi-layer boards are best achieved using specialized equipment and processes found in professional manufacturing facilities.

5. Time-Consuming and Labor-Intensive

Lengthy Preparation and Etching Process

Creating a PCB through home etching is a time-consuming process that involves multiple steps, including designing the circuit, transferring the design to the copper board, preparing the etching solution, and carefully monitoring the etching progress. This labor-intensive process can be frustrating and may not be an efficient use of time for most hobbyists.

Increased Likelihood of Errors and Rework

The manual nature of home PCB etching increases the likelihood of errors and the need for rework. Even small mistakes during the process can result in non-functional boards, requiring additional time and effort to correct.

6. Cost Considerations

Initial Investment in Equipment and Supplies

While home PCB etching may seem like a cost-effective option, the initial investment in equipment and supplies can be significant. Purchasing items such as a UV exposure unit, etching tanks, and safety gear can quickly add up, making it less economical than outsourcing PCB production to a professional manufacturer.

Higher Cost Per Board for Small Quantities

For small-scale production or one-off projects, the cost per board for home etching can be relatively high due to the fixed costs associated with materials and equipment. Professional PCB manufacturers can offer more competitive pricing, especially for larger quantities, thanks to their economies of scale.

7. Limited Scalability

Difficulty in Scaling Up Production

As projects grow in complexity or require larger quantities, home PCB etching becomes increasingly impractical. The manual nature of the process and the limitations of home equipment make it challenging to scale up production to meet increased demand.

Inability to Meet Tight Deadlines

In situations where time is of the essence, relying on home PCB etching can be risky. The lengthy and unpredictable nature of the process makes it difficult to meet tight deadlines, which can be crucial for certain projects or applications.

8. Lack of Professional-Grade Quality Control

Absence of Rigorous Testing and Inspection

Professional PCB manufacturers employ strict quality control measures, including automated optical inspection (AOI), electrical testing, and other rigorous checks to ensure the reliability and performance of their products. Home-etched PCBs lack this level of quality control, leading to a higher risk of defects and failures.

Potential for Reduced Reliability and Longevity

Without professional-grade quality control, home-etched PCBs may have a shorter lifespan and be more prone to failures compared to professionally manufactured boards. This can be particularly problematic for applications where reliability is critical, such as in medical devices or automotive systems.

9. Availability of Affordable and High-Quality Alternatives

Improved Accessibility of Professional PCB Fabrication Services

In recent years, there has been a significant increase in the availability and affordability of professional PCB fabrication services. Many online vendors now offer low-cost, quick-turn PCB manufacturing, making it easier than ever to obtain high-quality boards without the need for home etching.

Benefits of Outsourcing PCB Production

Outsourcing PCB production to professional manufacturers offers numerous benefits, including:

- Access to advanced manufacturing capabilities and materials

- Consistent and reliable results

- Faster turnaround times

- Cost-effective solutions for both small and large quantities

- Strict quality control and adherence to industry standards

By leveraging the expertise and resources of professional PCB fabricators, hobbyists and engineers can focus on designing and innovating rather than struggling with the challenges and limitations of home etching.

Frequently Asked Questions (FAQ)

1. Is it legal to etch PCBs at home?

While it may be legal to etch PCBs at home, it is crucial to check local regulations regarding the use and disposal of hazardous chemicals. Improper handling and disposal of these substances can lead to legal consequences and environmental damage.

2. Can I use safer alternatives to traditional etching chemicals?

Some alternative etching methods, such as using vinegar or salt water, have been explored by hobbyists. However, these methods often produce inferior results and may not be suitable for more complex designs. Additionally, they still pose some level of risk and require proper safety precautions.

3. How much does it cost to have a PCB professionally manufactured?

The cost of professional PCB manufacturing varies depending on factors such as board size, complexity, quantity, and turnaround time. Many online PCB fabricators offer prices starting at a few dollars per board for small quantities, with discounts available for larger orders.

4. How long does it take to receive a professionally manufactured PCB?

Turnaround times for professional PCB manufacturing have significantly improved in recent years. Many online vendors offer standard lead times of 1-2 weeks, with expedited options available for an additional cost. Some services even provide same-day or 24-hour turnaround for urgent projects.

5. Are there any situations where home PCB etching might be appropriate?

In general, we strongly recommend against home PCB etching due to the numerous risks and challenges involved. However, if you have the proper safety equipment, a well-ventilated workspace, and a thorough understanding of the process and associated risks, you may consider home etching for very simple, low-stakes projects. It is essential to prioritize safety and environmental responsibility above all else.

In conclusion, while home PCB etching may seem like an appealing option for hobbyists and DIY enthusiasts, the numerous risks and challenges associated with the process far outweigh any potential benefits. By understanding the health and safety concerns, environmental impact, inconsistent results, limited design capabilities, time-consuming nature, cost considerations, scalability issues, and lack of professional-grade quality control, it becomes clear that outsourcing PCB production to professional manufacturers is the most responsible and efficient choice. With the increasing availability and affordability of high-quality PCB fabrication services, there has never been a better time to leverage the expertise and resources of professional vendors to bring your electronic projects to life.

Leave a Reply