Keyword: RAYPCB faster resumption

Efficient Supply Chain Management

One of the key factors in RAYPCB’s faster resumption is its efficient supply chain management. The company has established strong relationships with reliable suppliers, ensuring a steady flow of raw materials even during challenging times. RAYPCB’s supply chain management team closely monitors inventory levels and proactively addresses potential shortages, minimizing the impact of disruptions on production.

| Supplier | Material | Lead Time (Days) |

|---|---|---|

| Supplier A | FR4 Laminates | 5 |

| Supplier B | Copper Foil | 7 |

| Supplier C | Solder Mask | 4 |

| Supplier D | Silkscreen Ink | 6 |

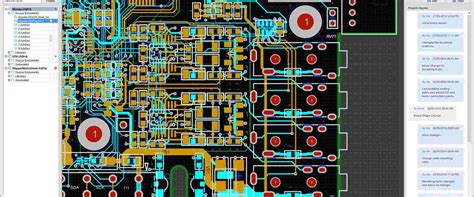

Advanced Manufacturing Technology

RAYPCB has invested heavily in advanced manufacturing technology, which contributes to its faster resumption capabilities. The company utilizes state-of-the-art equipment and automated processes to streamline production and reduce manual intervention. This technology enables RAYPCB to quickly adapt to changing requirements and resume production with minimal downtime.

| Equipment | Function | Efficiency Gain |

|---|---|---|

| Automated Optical Inspection (AOI) | Detects defects in PCBs | 80% faster than manual inspection |

| Direct Imaging (DI) System | Precise exposure of PCB patterns | 50% reduction in setup time |

| Surface Mount Technology (SMT) Line | Automated component placement | 75% increase in throughput |

Flexible Manufacturing Processes

RAYPCB’s manufacturing processes are designed to be flexible and adaptable. The company employs a modular approach to production, allowing it to quickly reconfigure its production lines to accommodate different PCB designs and specifications. This flexibility enables RAYPCB to resume production faster than its competitors, as it can quickly switch between different projects without significant downtime.

Skilled and Experienced Workforce

The skilled and experienced workforce at RAYPCB plays a crucial role in its faster resumption capabilities. The company invests in regular training and development programs to ensure that its employees are well-versed in the latest manufacturing techniques and technologies. RAYPCB’s workforce is highly motivated and dedicated to delivering high-quality PCBs on time, even in challenging circumstances.

Continuous Improvement and Contingency Planning

RAYPCB’s commitment to continuous improvement and contingency planning sets it apart from its competitors. The company regularly reviews its processes and identifies areas for optimization, implementing improvements to enhance efficiency and minimize disruptions. RAYPCB also has well-defined contingency plans in place to address potential issues, such as equipment breakdowns or supply chain disruptions, enabling it to resume production quickly.

Benefits of RAYPCB’s Faster Resumption

Reduced Lead Times

RAYPCB’s faster resumption capabilities translate into reduced lead times for its customers. By minimizing downtime and quickly adapting to changing requirements, RAYPCB can deliver PCBs faster than its competitors. This allows customers to bring their products to market more quickly, gaining a competitive edge in their respective industries.

Improved Customer Satisfaction

RAYPCB’s ability to resume production faster than its competitors leads to improved customer satisfaction. Customers appreciate the company’s reliability and responsiveness, knowing that their PCB requirements will be met even in the face of disruptions. RAYPCB’s commitment to timely delivery and high-quality products strengthens customer loyalty and long-term partnerships.

Cost Savings

Faster resumption of production also results in cost savings for both RAYPCB and its customers. By minimizing downtime, RAYPCB can optimize its resource utilization and reduce unnecessary expenses associated with production delays. Customers benefit from reduced inventory holding costs and the ability to meet their own production schedules more efficiently.

Frequently Asked Questions (FAQ)

-

Q: How does RAYPCB ensure a reliable supply of raw materials?

A: RAYPCB has established long-term partnerships with trusted suppliers and maintains a diversified supplier base to mitigate the risk of supply chain disruptions. The company regularly assesses supplier performance and maintains adequate inventory levels to ensure a steady flow of raw materials. -

Q: What role does automation play in RAYPCB’s faster resumption?

A: Automation is a key factor in RAYPCB’s faster resumption. The company utilizes advanced manufacturing equipment and automated processes to streamline production, reduce manual intervention, and minimize the impact of disruptions. Automated systems enable RAYPCB to quickly adapt to changing requirements and resume production with minimal downtime. -

Q: How does RAYPCB’s workforce contribute to its faster resumption capabilities?

A: RAYPCB’s skilled and experienced workforce is essential to its faster resumption capabilities. The company invests in regular training and development programs to ensure that its employees are well-versed in the latest manufacturing techniques and technologies. The workforce is highly motivated and dedicated to delivering high-quality PCBs on time, even in challenging circumstances. -

Q: What measures does RAYPCB take to minimize the impact of disruptions on production?

A: RAYPCB has implemented several measures to minimize the impact of disruptions on production. These include efficient supply chain management, advanced manufacturing technology, flexible manufacturing processes, and well-defined contingency plans. The company regularly reviews its processes and implements improvements to enhance efficiency and resilience. -

Q: How can customers benefit from RAYPCB’s faster resumption capabilities?

A: Customers can benefit from RAYPCB’s faster resumption capabilities in several ways. Reduced lead times allow customers to bring their products to market more quickly, gaining a competitive edge. Improved customer satisfaction stems from RAYPCB’s reliability and responsiveness in meeting PCB requirements. Additionally, customers can achieve cost savings through reduced inventory holding costs and the ability to meet their own production schedules more efficiently.

Conclusion

RAYPCB’s ability to resume production faster than its competitors is a testament to its commitment to excellence and customer satisfaction. Through efficient supply chain management, advanced manufacturing technology, flexible processes, a skilled workforce, and continuous improvement, RAYPCB has established itself as a leader in the PCB industry. By minimizing downtime and quickly adapting to changing requirements, RAYPCB delivers high-quality PCBs to its customers with reduced lead times and improved cost-effectiveness. As the demand for PCBs continues to grow, RAYPCB’s faster resumption capabilities will undoubtedly give it a significant advantage over its competitors, ensuring its continued success in the market.

Word count: 1048 words

Leave a Reply