Introduction to PCB Layers

Printed Circuit Boards (PCBs) are essential components in modern electronics, providing a platform for interconnecting electronic components and facilitating signal transmission. One of the critical aspects of PCB design is the concept of layers. PCB layers play a vital role in determining the functionality, performance, and reliability of electronic devices. In this article, we will explore the fundamentals of PCB layers, their types, and their significance in PCB design and manufacturing.

What are PCB Layers?

PCB layers refer to the individual conductive planes that make up a printed circuit board. These layers are stacked and laminated together to form a complete PCB Assembly. Each layer serves a specific purpose, such as signal routing, power distribution, or grounding. The number of layers in a PCB can vary depending on the complexity and requirements of the electronic design.

Types of PCB Layers

PCBs can be classified based on the number of layers they contain. The most common types of PCBs based on layers are:

- Single-Layer PCB

- Double-layer PCB

- Multi-layer PCB

Single-layer PCB

A single-layer PCB, also known as a single-sided PCB, consists of a single conductive layer on one side of the substrate material. The conductive layer is typically made of copper and is used for component placement and signal routing. Single-layer PCBs are the simplest and most cost-effective type of PCB, suitable for basic electronic circuits with low complexity.

Double-layer PCB

A double-layer PCB, also referred to as a double-sided PCB, has two conductive layers, one on each side of the substrate. The two layers are interconnected through conductive vias, which are small holes drilled through the board and plated with conductive material. Double-layer PCBs offer increased routing flexibility and higher component density compared to single-layer PCBs. They are commonly used in moderately complex electronic designs.

Multi-layer PCB

Multi-layer PCBs consist of three or more conductive layers stacked and laminated together. The layers are separated by insulating material, typically a dielectric substrate. Multi-layer PCBs provide enhanced signal integrity, improved power distribution, and better electromagnetic interference (EMI) shielding. They are used in high-density, complex electronic systems that require advanced functionality and performance.

The table below summarizes the characteristics of different types of PCBs based on layers:

| PCB Type | Number of Layers | Complexity | Cost | Applications |

|---|---|---|---|---|

| Single-layer | 1 | Low | Low | Simple electronic circuits |

| Double-layer | 2 | Moderate | Medium | Moderately complex designs |

| Multi-layer | 3 or more | High | High | High-density, complex electronic systems |

Significance of PCB Layers

PCB layers play a crucial role in the overall performance and functionality of electronic devices. Let’s explore the significance of PCB layers in more detail.

Signal Integrity

One of the primary purposes of PCB layers is to ensure signal integrity. Signal integrity refers to the ability of a PCB to maintain the quality and reliability of electrical signals as they travel through the board. Multi-layer PCBs offer improved signal integrity by providing dedicated signal layers and ground planes. The ground planes help to minimize crosstalk and reduce electromagnetic interference, ensuring cleaner and more stable signals.

Power Distribution

Efficient power distribution is another critical aspect of PCB design. Dedicated power planes in multi-layer PCBs provide low-impedance paths for power delivery to components. By having separate power layers, the PCB can ensure stable and reliable power supply to all components, reducing voltage drops and minimizing noise. This is particularly important in high-power applications or designs with sensitive analog circuits.

EMI Shielding

Electromagnetic interference (EMI) is a common issue in electronic systems, where unwanted electromagnetic energy can disrupt the normal operation of circuits. PCB layers can help mitigate EMI by incorporating shielding techniques. Ground planes and power planes in multi-layer PCBs act as shields, reducing the emission and susceptibility of electromagnetic interference. Proper layer stackup and grounding strategies can significantly improve the EMI performance of a PCB.

Component Placement and Routing

PCB layers provide the necessary space for component placement and signal routing. The availability of multiple layers allows for higher component density and more efficient routing. Components can be strategically placed on different layers to optimize signal paths and minimize interference. Multi-layer PCBs enable complex routing patterns, such as via-in-pad and blind/buried vias, which enhance design flexibility and miniaturization.

Thermal Management

Thermal management is a critical consideration in PCB design, especially for high-power applications. PCB layers can contribute to effective thermal management by providing dedicated thermal layers or using thermally conductive materials. Thermal vias and copper pours on specific layers can help dissipate heat away from components, preventing overheating and ensuring reliable operation.

PCB Layer Stackup

The arrangement and order of PCB layers is known as the layer stackup. The layer stackup defines the sequence of conductive and insulating layers in a PCB. Proper layer stackup design is crucial for optimizing signal integrity, power distribution, and manufacturability.

A typical multi-layer PCB Stackup may consist of the following layers:

- Top Layer: Components, signal traces, and surface finish

- Ground Plane: Provides a low-impedance return path for signals

- Signal Layer: Inner layer for signal routing

- Power Plane: Distributes power to components

- Signal Layer: Additional inner layer for signal routing

- Bottom Layer: Components, signal traces, and surface finish

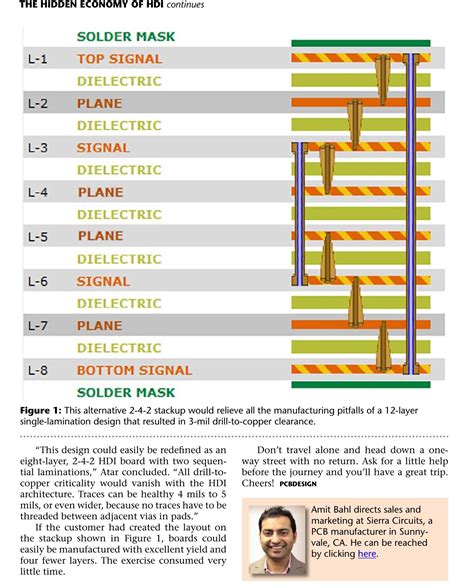

The image below illustrates a simplified representation of a multi-layer PCB stackup:

Top Layer (Components and Signal Traces)

==========================================

Ground Plane

==========================================

Signal Layer

==========================================

Power Plane

==========================================

Signal Layer

==========================================

Bottom Layer (Components and Signal Traces)

The specific layer stackup design depends on the requirements of the electronic design, such as the number of layers needed, the signal integrity considerations, and the manufacturing constraints.

Manufacturing Considerations

When designing a PCB, it is essential to consider the manufacturing process and its impact on the layers. Some key manufacturing considerations related to PCB layers include:

-

Layer Thickness: The thickness of each layer in a PCB stackup should be carefully chosen to ensure proper impedance control and manufacturability. Standard copper thicknesses, such as 1 oz. (35 µm) or 2 oz. (70 µm), are commonly used.

-

Dielectric Material: The choice of dielectric material between layers affects the electrical properties and performance of the PCB. Common dielectric materials include FR-4, Rogers, and Isola. The dielectric constant (Dk) and dissipation factor (Df) of the material should be considered for high-speed designs.

-

Minimum Feature Size: The minimum feature size, such as trace width and spacing, via diameter, and pad size, is determined by the manufacturing capabilities of the PCB fabricator. It is important to adhere to the minimum feature size guidelines to ensure reliable manufacturing and avoid issues like signal integrity problems or manufacturing defects.

-

Layer Registration: Accurate layer registration is crucial for proper alignment of vias, pads, and traces across different layers. Misalignment can lead to manufacturing defects and compromised signal integrity. PCB fabricators use registration marks and advanced alignment techniques to ensure precise layer registration.

-

Via Technology: The choice of via technology, such as through-hole vias, blind vias, or buried vias, affects the manufacturability and cost of the PCB. Through-hole vias are the most common and cost-effective, while blind and buried vias offer higher density and design flexibility but come with increased manufacturing complexity and cost.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between a single-layer and a double-layer PCB?

A: A single-layer PCB has a conductive layer on only one side of the substrate, while a double-layer PCB has conductive layers on both sides of the substrate. Double-layer PCBs offer more routing flexibility and higher component density compared to single-layer PCBs. -

Q: How do multi-layer PCBs improve signal integrity?

A: Multi-layer PCBs improve signal integrity by providing dedicated signal layers and ground planes. The ground planes help to minimize crosstalk and reduce electromagnetic interference, resulting in cleaner and more stable signals. The separation of signal layers and the use of proper grounding techniques contribute to better signal integrity. -

Q: What is the purpose of power planes in a multi-layer PCB?

A: Power planes in a multi-layer PCB provide low-impedance paths for power delivery to components. They ensure stable and reliable power supply by reducing voltage drops and minimizing noise. Power planes also help in distributing power efficiently across the PCB, which is crucial for high-power applications or designs with sensitive analog circuits. -

Q: How do PCB layers contribute to EMI shielding?

A: PCB layers, particularly ground planes and power planes in multi-layer PCBs, act as shields against electromagnetic interference (EMI). These layers help to reduce the emission and susceptibility of electromagnetic energy, minimizing the impact of EMI on the normal operation of circuits. Proper layer stackup and grounding strategies play a vital role in improving the EMI performance of a PCB. -

Q: What factors should be considered when designing the layer stackup of a PCB?

A: When designing the layer stackup of a PCB, several factors should be considered, including signal integrity requirements, power distribution needs, thermal management, manufacturing constraints, and cost. The number of layers, the arrangement of signal, power, and ground layers, the choice of dielectric materials, and the thickness of each layer are all important considerations in layer stackup design.

Conclusion

PCB layers are fundamental building blocks of printed circuit boards, playing a crucial role in the functionality, performance, and reliability of electronic devices. Understanding the types of PCB layers, their significance, and the manufacturing considerations is essential for designing and manufacturing high-quality PCBs.

From single-layer PCBs for simple circuits to multi-layer PCBs for complex systems, the choice of layers depends on the specific requirements of the electronic design. PCB layers contribute to signal integrity, power distribution, EMI shielding, component placement, routing, and thermal management.

Proper layer stackup design, considering factors such as signal integrity, manufacturing constraints, and cost, is crucial for optimizing the performance and manufacturability of PCBs. Close collaboration between PCB designers and manufacturers is necessary to ensure the successful realization of the desired PCB layering.

As electronic systems continue to advance in complexity and functionality, the importance of PCB layers will only grow. By leveraging the capabilities of different PCB layers and designing them effectively, engineers can create robust and reliable electronic products that meet the ever-increasing demands of modern technology.

Leave a Reply