Why are PCB Fiducials Important?

PCB fiducials play a crucial role in the automated assembly process of printed circuit boards. Here are some key reasons why fiducials are important:

-

Accurate component placement: Fiducials serve as reference points for pick-and-place machines and other automated assembly equipment to precisely locate and place components on the PCB. This ensures that components are positioned correctly and with proper alignment.

-

Improved manufacturing efficiency: By using fiducials, the assembly process can be automated, reducing human error and increasing production speed. This leads to higher throughput and lower manufacturing costs.

-

Accommodating smaller components: As electronic components continue to shrink in size, accurate placement becomes increasingly challenging. Fiducials enable the use of high-precision assembly equipment, allowing for the reliable placement of small components such as chip-scale packages (CSPs) and ball grid arrays (BGAs).

-

Ensuring product quality: Proper component alignment and placement are essential for the functionality and reliability of the final product. Fiducials help minimize assembly errors, reducing the risk of defects and improving overall product quality.

Types of PCB Fiducials

There are several types of fiducials used in PCB Assembly, each serving a specific purpose. The most common types include:

Global Fiducials

Global fiducials, also known as panel fiducials, are located on the edges of the PCB panel and are used to establish the overall orientation and position of the board. They are typically larger than local fiducials and are used by the assembly equipment to locate and align the panel before processing individual boards.

Local Fiducials

Local fiducials, also called board fiducials or component fiducials, are smaller marks placed on the individual PCB. They are used to fine-tune the placement of components and ensure accurate alignment. Local fiducials are typically located near critical components or in areas where high placement accuracy is required.

Mixed Fiducials

Mixed fiducials are a combination of global and local fiducials. They are used when the PCB design requires both panel-level and board-level alignment. Mixed fiducials provide a hierarchical reference system, allowing for coarse alignment using global fiducials and fine alignment using local fiducials.

Fiducial Design Considerations

When designing fiducials for a PCB, several factors must be considered to ensure optimal performance during the assembly process. Some key design considerations include:

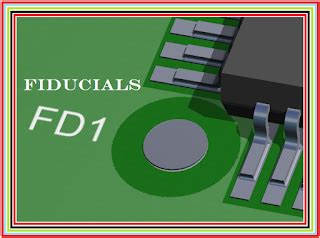

Fiducial Shape and Size

Fiducials are typically circular, as this shape is easily recognized by vision systems used in assembly equipment. The size of the fiducial should be large enough to be easily detectable but small enough to minimize the space they occupy on the PCB. A common size range for fiducials is between 1.0 mm and 3.0 mm in diameter.

Fiducial Placement

The placement of fiducials on the PCB is crucial for accurate component alignment. Fiducials should be positioned in areas that are easily accessible by the assembly equipment and provide a clear line of sight. They should also be placed away from components and other features that may obstruct their visibility.

Fiducial Contrast

Fiducials must have sufficient contrast against the PCB substrate to be easily detectable by vision systems. This is typically achieved by using a copper pad with a solder mask opening, creating a bright, reflective surface that stands out against the darker PCB substrate.

Clearance and Solder Mask

Adequate clearance should be provided around the fiducial to ensure that nearby components or features do not interfere with its visibility. A solder mask opening should be used to expose the copper pad, creating a clear target for the vision system.

Fiducial Placement Guidelines

To ensure optimal performance and accuracy, follow these guidelines when placing fiducials on a PCB:

-

Quantity: Use at least three fiducials per PCB, preferably located near the corners of the board. This allows for accurate triangulation and alignment of the board during assembly.

-

Symmetry: Place fiducials symmetrically on the PCB whenever possible. This helps to minimize the impact of any distortion or warping of the board during the manufacturing process.

-

Clearance: Ensure that there is sufficient clearance around the fiducials, free from components, traces, or other features that may obstruct their visibility. A minimum clearance of 3 mm is generally recommended.

-

Accessibility: Fiducials should be placed in areas that are easily accessible by the assembly equipment. Avoid placing fiducials near the edges of the board or in areas that may be obscured by fixtures or other tooling.

-

Consistency: Maintain consistent fiducial placement across all boards in a panel. This allows for efficient panel-level alignment and reduces the need for individual board adjustments.

Fiducial Materials and Fabrication

Fiducials are typically fabricated using the same materials and processes as the rest of the PCB. The most common materials and fabrication methods include:

Copper Pads

Copper pads are the most widely used material for fiducials. They are created by etching a circular pad on the copper layer of the PCB, similar to the pads used for component placement. Copper pads provide excellent contrast and reflectivity, making them easily detectable by vision systems.

Solder Mask Openings

Solder mask openings are used to expose the copper pads, creating a clear target for the vision system. The opening should be slightly larger than the copper pad to ensure that the entire pad is visible and free from any solder mask residue.

Silkscreen

In some cases, silkscreen markings may be used in conjunction with copper pads to create fiducials. The silkscreen provides additional contrast and can help to visually identify the location of the fiducial. However, silkscreen markings should not be relied upon solely, as they may be less accurate than copper pads.

Fiducial Recognition and Vision Systems

Automated assembly equipment uses vision systems to detect and locate fiducials on the PCB. These systems typically employ camera-based technology and specialized software to recognize the unique features of the fiducials.

Illumination

Proper illumination is crucial for accurate fiducial recognition. Vision systems often use a combination of bright-field and dark-field illumination to enhance the contrast between the fiducial and the PCB substrate. This ensures that the fiducial is clearly visible and can be reliably detected by the system.

Image Processing

Once an image of the fiducial is captured, the vision system uses image processing algorithms to analyze the features and determine the exact location of the fiducial. These algorithms may include edge detection, pattern matching, and centroid calculation to accurately pinpoint the center of the fiducial.

Coordinate Transformation

The location of the fiducial is then translated into machine coordinates, which are used by the assembly equipment to align and place components on the PCB. This coordinate transformation takes into account the position and orientation of the fiducial relative to the PCB and the assembly equipment.

Best Practices for Using Fiducials

To ensure the effective use of fiducials in PCB assembly, consider the following best practices:

-

Design for manufacturability: Incorporate fiducials into the PCB design from the outset, taking into account the specific requirements of the assembly process and equipment.

-

Collaborate with manufacturers: Work closely with PCB fabrication and assembly partners to ensure that the fiducial design and placement meet their specific needs and capabilities.

-

Maintain consistency: Use consistent fiducial designs and placement across all PCBs in a project to streamline the assembly process and reduce the need for equipment adjustments.

-

Verify fiducial quality: Inspect fiducials during the PCB fabrication process to ensure that they meet the required specifications for size, shape, and contrast.

-

Monitor assembly performance: Regularly monitor the performance of the assembly process, paying attention to any issues related to fiducial recognition or component placement accuracy. Address any problems promptly to maintain high-quality output.

Frequently Asked Questions (FAQ)

1. What is the optimal size for a PCB fiducial?

The optimal size for a PCB fiducial depends on the specific requirements of the assembly equipment and process. Generally, fiducials range from 1.0 mm to 3.0 mm in diameter, with 1.5 mm being a common size. The size should be large enough to be easily detectable by the vision system but small enough to minimize the space they occupy on the PCB.

2. Can fiducials be placed on both sides of a PCB?

Yes, fiducials can be placed on both sides of a PCB if the assembly process requires components to be placed on both sides. In this case, it is essential to ensure that the fiducials on each side are properly aligned and do not interfere with each other.

3. How does the placement of fiducials impact assembly accuracy?

The placement of fiducials directly impacts the accuracy of component placement during the assembly process. Fiducials should be placed in locations that provide a clear line of sight for the vision system and are easily accessible by the assembly equipment. Proper placement ensures that the equipment can accurately locate and align the PCB, resulting in precise component placement.

4. Are there any specific requirements for fiducial placement in high-density PCB designs?

In high-density PCB designs, fiducial placement can be more challenging due to limited space and the presence of numerous components. In these cases, it may be necessary to use smaller fiducials or place them in strategic locations to ensure adequate clearance and visibility. Collaboration with the assembly partner is crucial to determine the best fiducial placement strategy for high-density designs.

5. Can fiducials be used for other purposes besides component placement?

While the primary purpose of fiducials is to assist in accurate component placement during assembly, they can also be used for other purposes, such as:

- Alignment of multiple PCB Layers during the fabrication process

- Registration of solder paste stencils for precise solder paste application

- Alignment of test fixtures and probe cards for electrical testing and debugging

However, it is essential to ensure that any additional uses of fiducials do not interfere with their primary function in the assembly process.

Conclusion

PCB fiducials play a critical role in ensuring accurate component placement and alignment during the automated assembly process. By serving as reference points for vision systems and assembly equipment, fiducials enable high-precision manufacturing, improved efficiency, and enhanced product quality.

When designing and using fiducials, it is essential to consider factors such as size, shape, placement, and contrast to ensure optimal performance. Collaborating closely with PCB fabrication and assembly partners and following best practices can help to maximize the benefits of fiducials and streamline the manufacturing process.

As PCB technology continues to evolve, with ever-increasing component density and miniaturization, the importance of fiducials in ensuring accurate and reliable assembly will only continue to grow. By understanding the role and proper use of fiducials, PCB designers and manufacturers can overcome the challenges of modern electronics production and deliver high-quality products to market.

| Fiducial Type | Typical Size (mm) | Placement |

|---|---|---|

| Global Fiducial | 2.0 – 3.0 | Panel edges, used for panel alignment |

| Local Fiducial | 1.0 – 2.0 | Near critical components, for fine alignment |

| Mixed Fiducial | 1.5 – 2.5 | Combination of global and local placement |

Leave a Reply