What are Water Level Sensors?

Water level sensors are devices that measure the level of water or other liquids in a container or system. They provide accurate and real-time data on the liquid level, which is crucial for monitoring and controlling various processes. These sensors use different technologies to detect the water level, such as float switches, ultrasonic sensors, capacitive sensors, and pressure transducers.

Types of Water Level Sensors

There are several types of water level sensors available in the market, each with its own advantages and limitations. Let’s take a closer look at some of the most common types:

Float Switches

Float switches are one of the simplest and most cost-effective types of water level sensors. They consist of a float attached to a switch, which is activated when the water level reaches a certain point. Float switches are reliable and easy to install, making them a popular choice for many applications.

Ultrasonic Sensors

Ultrasonic sensors use high-frequency sound waves to measure the distance between the sensor and the water surface. They emit a sound pulse and measure the time it takes for the echo to return, which is then used to calculate the water level. Ultrasonic sensors are highly accurate and can measure levels in a wide range of liquids, including those with foam or turbulence.

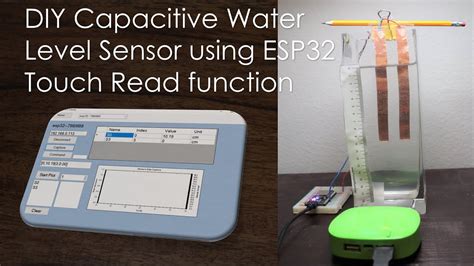

Capacitive Sensors

Capacitive sensors measure the water level by detecting changes in the capacitance between two electrodes. As the water level rises, the capacitance increases, which is then converted into a level measurement. Capacitive sensors are highly sensitive and can detect even small changes in the water level.

Pressure Transducers

Pressure transducers measure the water level by detecting the hydrostatic pressure exerted by the liquid. They consist of a diaphragm that deforms under pressure, which is then converted into an electrical signal. Pressure transducers are highly accurate and can measure levels in deep tanks or wells.

Working Principles of Water Level Sensors

Water level sensors use different working principles depending on their type. Let’s explore the working principles of some of the most common types:

Float Switches

Float switches work on the principle of buoyancy. As the water level rises, the float rises with it, activating the switch when it reaches a certain point. When the water level drops, the float falls, deactivating the switch. Float switches are simple and reliable, but they can only detect discrete levels and may not be suitable for continuous level monitoring.

Ultrasonic Sensors

Ultrasonic sensors work on the principle of sound wave reflection. They emit a high-frequency sound pulse that travels through the air and reflects off the water surface. The sensor measures the time it takes for the echo to return and uses this information to calculate the distance between the sensor and the water surface. Ultrasonic sensors are highly accurate and can measure levels in a wide range of liquids, but they may be affected by foam or turbulence.

Capacitive Sensors

Capacitive sensors work on the principle of capacitance. They consist of two electrodes separated by an insulating material, such as air or a dielectric. As the water level rises, it displaces the insulating material, increasing the capacitance between the electrodes. The sensor measures this change in capacitance and converts it into a level measurement. Capacitive sensors are highly sensitive and can detect even small changes in the water level, but they may be affected by changes in the dielectric constant of the liquid.

Pressure Transducers

Pressure transducers work on the principle of hydrostatic pressure. They measure the pressure exerted by the liquid on a diaphragm, which deforms under pressure. The deformation is then converted into an electrical signal using a strain gauge or a piezoelectric element. Pressure transducers are highly accurate and can measure levels in deep tanks or wells, but they may be affected by changes in the density of the liquid.

Applications of Water Level Sensors

Water level sensors have a wide range of applications in various industries and fields. Let’s explore some of the most common applications:

Industrial Processes

Water level sensors are widely used in industrial processes, such as chemical manufacturing, food processing, and pharmaceuticals. They are used to monitor and control the level of liquids in tanks, reactors, and other vessels. Water level sensors ensure that the process runs smoothly and safely, preventing overfilling or running dry.

Water Treatment

Water level sensors are essential components in water treatment plants, where they are used to monitor and control the level of water in various stages of the treatment process. They are used in clarifiers, filters, and storage tanks to ensure that the water is treated efficiently and effectively.

Irrigation

Water level sensors are used in irrigation systems to monitor and control the level of water in reservoirs, canals, and other water bodies. They ensure that the crops receive the right amount of water at the right time, optimizing water use and preventing waste.

Flood Monitoring

Water level sensors are used in flood monitoring systems to detect and alert authorities of rising water levels in rivers, lakes, and other water bodies. They provide real-time data on the water level, enabling authorities to take timely action to prevent or mitigate the impact of floods.

Wastewater Management

Water level sensors are used in wastewater management systems to monitor and control the level of wastewater in various stages of the treatment process. They ensure that the wastewater is treated efficiently and effectively, preventing overflows and spills.

Frequently Asked Questions (FAQ)

1. What is the accuracy of water level sensors?

The accuracy of water level sensors varies depending on their type and application. Ultrasonic sensors and pressure transducers are typically the most accurate, with accuracies of up to ±0.25% of the full scale. Capacitive sensors and float switches are less accurate, with accuracies of up to ±1% of the full scale.

2. Can water level sensors be used in dirty or turbid liquids?

Yes, some water level sensors can be used in dirty or turbid liquids. Ultrasonic sensors and pressure transducers are particularly well-suited for these applications, as they are not affected by the color or clarity of the liquid. However, capacitive sensors and float switches may not be suitable for dirty or turbid liquids, as they can be affected by the buildup of debris or contamination.

3. What is the maximum depth that water level sensors can measure?

The maximum depth that water level sensors can measure depends on their type and design. Pressure transducers can typically measure depths of up to 100 meters or more, while ultrasonic sensors and capacitive sensors are limited to depths of up to 10 meters or less. Float switches are typically limited to depths of up to 5 meters or less.

4. How do I choose the right water level sensor for my application?

Choosing the right water level sensor for your application depends on several factors, such as the type of liquid, the range of levels to be measured, the accuracy required, and the environmental conditions. You should consider the advantages and limitations of each type of sensor and consult with a qualified engineer or supplier to determine the best option for your specific needs.

5. How often do water level sensors need to be calibrated?

The frequency of calibration for water level sensors depends on their type and application. Most sensors should be calibrated at least once a year, or more frequently if they are used in critical applications or harsh environments. Calibration ensures that the sensor is providing accurate and reliable measurements and helps to prevent errors or failures.

Conclusion

Water level sensors are essential components in various applications, from industrial processes to environmental monitoring. They provide accurate and real-time data on the level of water or other liquids, enabling users to monitor and control their processes efficiently and effectively. There are several types of water level sensors available, each with its own advantages and limitations, and choosing the right sensor for your application requires careful consideration of your specific needs and requirements. By understanding the working principles, applications, and frequently asked questions about water level sensors, you can make informed decisions and ensure the success of your project.

| Type of Sensor | Accuracy | Max Depth | Suitable for Dirty Liquids |

|---|---|---|---|

| Float Switches | ±1% | 5 meters | No |

| Ultrasonic Sensors | ±0.25% | 10 meters | Yes |

| Capacitive Sensors | ±1% | 10 meters | No |

| Pressure Transducers | ±0.25% | 100 meters | Yes |

Leave a Reply