What is an Inductor?

An inductor is a passive electronic component that stores energy in the form of a magnetic field when an electric current flows through it. It consists of a coil of wire, often wound around a core material, which can be air, ferrite, or iron. The main function of an inductor is to oppose changes in the current flowing through it, creating a voltage drop across its terminals.

Inductors are characterized by their inductance, which is measured in henries (H). The inductance value represents the amount of energy stored in the magnetic field for a given current. Other important parameters include the current rating, frequency range, and quality factor (Q).

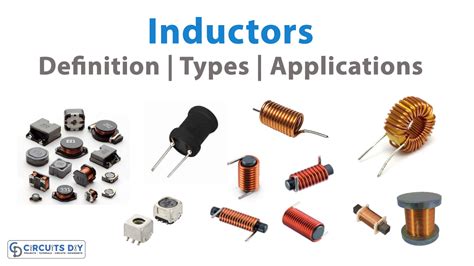

Types of Inductors

There are several types of inductors, each with its own unique properties and applications. Let’s dive into the most common Inductor Types:

Air Core Inductors

Air core inductors are the simplest type of inductor, consisting of a coil of wire without any magnetic core material. They have the following characteristics:

- Low inductance values (typically in the nanohenry range)

- High frequency operation (up to several GHz)

- Low Q factor

- No saturation effects

- Lightweight and compact

Applications:

– High-frequency circuits (e.g., RF and microwave)

– Resonant circuits

– Filters and oscillators

Ferrite Core Inductors

Ferrite core inductors use a ferrite material as the core, which is a ceramic compound made of iron oxide and other metals. They offer several advantages over air core inductors:

- Higher inductance values (up to several millihenries)

- Higher Q factor

- Smaller size for a given inductance value

- Good temperature stability

- Low cost

Applications:

– Switch-mode power supplies (SMPS)

– EMI suppression

– Noise filters

– DC/DC converters

Iron Core Inductors

Iron core inductors use a laminated iron core material, which provides high permeability and low loss. They have the following characteristics:

- High inductance values (up to several henries)

- High current handling capacity

- Low frequency operation (up to a few hundred kHz)

- Prone to saturation effects

- Larger size and weight compared to ferrite core inductors

Applications:

– Power transformers

– Audio transformers

– Low-frequency filters

– Motor control

Toroidal Inductors

Toroidal inductors are wound on a donut-shaped core, which can be made of ferrite, iron powder, or other magnetic materials. They offer several benefits:

- Compact size

- High inductance values

- Low electromagnetic interference (EMI)

- High efficiency

- Wide frequency range

Applications:

– Switch-mode power supplies (SMPS)

– EMI suppression

– Audio equipment

– Telecommunications

Surface Mount Inductors (SMD)

Surface mount inductors are designed for surface mount technology (SMT) assembly, allowing for automated placement on printed circuit boards (PCBs). They come in various types, such as ceramic core, ferrite core, and multilayer inductors. SMD inductors offer:

- Miniature size

- Low profile

- Wide range of inductance values

- Suitable for high-frequency applications

Applications:

– Mobile devices

– Portable electronics

– High-density PCB assemblies

– RF circuits

Molded Inductors

Molded inductors are encased in a plastic or epoxy resin, providing protection against environmental factors and mechanical stress. They are available in various core materials, such as ferrite and iron powder. Molded inductors offer:

- Robust construction

- Moisture resistance

- Wide temperature range

- Suitable for high-reliability applications

Applications:

– Automotive electronics

– Industrial control systems

– Medical devices

– Aerospace and defense

Variable Inductors

Variable inductors allow the inductance value to be adjusted by mechanical or electrical means. They can be classified into two main types:

- Manually adjustable inductors

- Inductance is varied by changing the position of a movable core or a sliding contact

-

Used in tunable filters, impedance matching circuits, and antenna tuners

-

Saturable reactors

- Inductance is controlled by a DC bias current, which saturates the core material

- Used in power control, voltage regulation, and current limiting applications

Inductor Selection Considerations

When selecting an inductor for your application, consider the following factors:

- Inductance value

- Current rating

- Frequency range

- Q factor

- Size and package

- Temperature coefficient

- Saturation current

- Self-resonant frequency (SRF)

- DC resistance (DCR)

- Cost

It’s essential to consult the manufacturer’s datasheet and application notes to ensure that the chosen inductor meets your specific requirements.

Inductor Applications

Inductors find applications in a wide range of electronic circuits and systems. Some common applications include:

- Power supplies and voltage regulators

- EMI and noise suppression

- Filters (low-pass, high-pass, band-pass)

- Resonant circuits and oscillators

- Impedance matching networks

- Energy storage and transfer

- Motor control and driver circuits

- Sensors and transducers

- Wireless Charging systems

- Audio and signal processing

Inductor Comparison Table

| Inductor Type | Inductance Range | Frequency Range | Q Factor | Core Material | Typical Applications |

|---|---|---|---|---|---|

| Air Core | nH to µH | Up to GHz | Low | None | RF, resonant circuits, filters |

| Ferrite Core | µH to mH | Up to MHz | Medium | Ferrite | SMPS, EMI suppression, noise filters |

| Iron Core | mH to H | Up to kHz | High | Laminated iron | Power transformers, audio, motor control |

| Toroidal | µH to H | Wide range | High | Various | SMPS, EMI suppression, audio |

| Surface Mount (SMD) | nH to mH | Wide range | Medium | Various | Mobile devices, RF circuits, high-density PCBs |

| Molded | µH to mH | Up to MHz | Medium | Various | Automotive, industrial, medical |

| Variable (Manual) | µH to mH | Up to MHz | Medium | Various | Tunable filters, impedance matching |

| Variable (Saturable) | mH to H | Up to kHz | Low | Various | Power control, voltage regulation |

Frequently Asked Questions (FAQ)

- What is the difference between an inductor and a transformer?

-

An inductor is a single winding component that stores energy in a magnetic field, while a transformer consists of two or more coupled windings that transfer energy between circuits through electromagnetic induction.

-

Can inductors be connected in series or parallel?

-

Yes, inductors can be connected in series or parallel. In series, the total inductance is the sum of individual inductances, while in parallel, the reciprocal of the total inductance is the sum of the reciprocals of individual inductances.

-

How do I calculate the inductance value for a specific application?

-

The required inductance value depends on factors such as the operating frequency, desired impedance, and circuit configuration. You can use formulas specific to your application or consult reference designs and application notes provided by inductor manufacturers.

-

What is the purpose of the core material in an inductor?

-

The core material in an inductor serves to increase the magnetic field strength and inductance value for a given number of turns. It also helps to reduce the size of the inductor and improve its efficiency.

-

How do I measure the inductance of an inductor?

- Inductance can be measured using an LCR meter, impedance analyzer, or by constructing a resonant circuit and measuring the resonant frequency. Some multimeters also have an inductance measurement function.

Conclusion

Inductors are vital components in electronic circuits, offering a wide range of types and characteristics to suit various applications. By understanding the different inductor types, their properties, and selection considerations, you can make an informed choice for your specific design requirements. Whether you need a compact SMD inductor for a mobile device, a high-current iron core inductor for a power supply, or a variable inductor for tuning, there is an inductor type that will meet your needs. As with any electronic component, it’s essential to consult the manufacturer’s datasheets and application notes to ensure optimal performance and reliability in your circuit.

Leave a Reply