Introduction to Stranded and Solid Wire

Copper wire is the most commonly used conductor in electrical and electronic applications due to its excellent conductivity, durability, and relatively low cost. When selecting the appropriate type of copper wire for a specific project, one of the key decisions is whether to use stranded or solid wire. Each type has its own unique characteristics, advantages, and disadvantages, making it crucial to understand the differences between them to ensure optimal performance and reliability.

In this comprehensive article, we will delve into the world of stranded and solid copper wire, comparing their properties, applications, and suitability for various power and signal transmission scenarios. By the end of this guide, you will have a clear understanding of when to use stranded wire and when to opt for solid wire, empowering you to make informed decisions for your electrical and electronic projects.

What is Stranded Wire?

Stranded wire consists of multiple thin copper strands that are twisted or bundled together to form a single conductor. The number of strands can vary depending on the wire gauge and intended application. Common strand counts include 7, 19, 37, and even higher numbers for specialized purposes.

Advantages of Stranded Wire

-

Flexibility: The multiple strands in stranded wire allow for greater flexibility compared to solid wire. This makes stranded wire ideal for applications where the wire needs to bend, flex, or conform to tight spaces, such as in moving parts or cable assemblies.

-

Durability: Stranded wire is more resistant to fatigue and breakage caused by repeated bending or vibration. The individual strands can move and adjust within the bundle, reducing stress on the conductor as a whole.

-

Reduced Skin Effect: At high frequencies, electrical current tends to flow more on the outer surface of a conductor, known as the skin effect. Stranded wire minimizes this effect due to its increased surface area, allowing for better high-frequency signal transmission compared to solid wire.

Disadvantages of Stranded Wire

-

Higher Cost: Stranded wire is generally more expensive than solid wire of the same gauge due to the additional manufacturing process required to bundle the strands together.

-

Difficulty in Termination: Stranded wire can be more challenging to terminate than solid wire. The individual strands must be properly aligned and secured to ensure a reliable connection, which may require specialized tools or techniques.

-

Increased Resistance: Although stranded wire has a larger cross-sectional area compared to solid wire of the same gauge, the gaps between the strands can slightly increase the overall resistance of the conductor.

What is Solid Wire?

Solid wire consists of a single, solid conductor with no internal strands. It is typically made from a single piece of drawn copper and is available in various gauges to suit different current-carrying capacities and mechanical requirements.

Advantages of Solid Wire

-

Ease of Termination: Solid wire is easier to terminate than stranded wire. It can be directly inserted into terminal blocks, soldered to circuit boards, or wrapped around screw terminals without the need for special preparation or tools.

-

Lower Resistance: Solid wire has a slightly lower resistance compared to stranded wire of the same gauge due to the absence of gaps between strands. This can result in marginally better conductivity and reduced power loss.

-

Cost-effective: Solid wire is generally less expensive than stranded wire of the same gauge due to its simpler manufacturing process.

Disadvantages of Solid Wire

-

Limited Flexibility: Solid wire is less flexible than stranded wire, making it more prone to breakage or fatigue when subjected to repeated bending or movement. It is not suitable for applications that require frequent flexing or conformity to tight spaces.

-

Susceptibility to Vibration: Solid wire is more susceptible to damage caused by vibration or mechanical stress. The rigid nature of the single conductor can lead to fatigue and eventual failure in high-vibration environments.

-

Skin Effect at High Frequencies: Solid wire is more affected by the skin effect at high frequencies compared to stranded wire. This can result in increased signal attenuation and reduced transmission efficiency in high-frequency applications.

Applications of Stranded and Solid Wire

Stranded Wire Applications

-

Flexible Cables: Stranded wire is commonly used in flexible cables, such as power cords, audio/video cables, and USB cables. The flexibility of stranded wire allows these cables to bend and flex without causing damage to the conductors.

-

Automotive Wiring: Stranded wire is extensively used in automotive wiring harnesses due to its ability to withstand vibration and movement. The flexibility of stranded wire ensures reliable connections and minimizes the risk of wire breakage in the dynamic environment of a vehicle.

-

Robotic and Machine Wiring: In applications involving moving parts or articulated joints, stranded wire is the preferred choice. Its flexibility enables the wire to move and flex with the machine components, reducing stress on the conductors and extending the lifespan of the wiring.

-

High-Frequency Signal Transmission: Stranded wire is often used in high-frequency signal transmission applications, such as radio frequency (RF) cables and high-speed data transmission lines. The reduced skin effect in stranded wire allows for better signal integrity and minimizes signal loss at higher frequencies.

Solid Wire Applications

-

Building Wiring: Solid wire is commonly used in residential and commercial building wiring for power distribution. The rigidity of solid wire makes it easier to route through walls, ceilings, and conduits, and its ease of termination simplifies connections to outlets, switches, and other fixed points.

-

Breadboarding and Prototyping: Solid wire is often used in electronic prototyping and breadboarding due to its ease of insertion into breadboard sockets and its ability to maintain a secure connection. The rigidity of solid wire helps keep the connections stable and reduces the risk of accidental disconnection.

-

PCB Wiring: Solid wire is frequently used for point-to-point wiring on printed circuit boards (PCBs). Its rigidity allows for precise routing and stable connections between components, ensuring reliable circuit operation.

-

Low-Frequency Signal Transmission: In low-frequency signal transmission applications, such as audio systems or basic control circuits, solid wire is often sufficient. The lower resistance and cost-effectiveness of solid wire make it a viable choice for these scenarios.

Stranded vs. Solid Wire: A Comparison Table

| Characteristic | Stranded Wire | Solid Wire |

|---|---|---|

| Flexibility | High | Low |

| Durability | High (resistant to fatigue) | Low (prone to breakage) |

| Termination | More difficult | Easier |

| Resistance | Slightly higher | Lower |

| Cost | Higher | Lower |

| Skin Effect | Reduced | More pronounced |

| Typical Applications | Flexible cables, automotive wiring | Building wiring, PCB wiring |

Frequently Asked Questions (FAQ)

-

Can I use stranded wire for building wiring?

While stranded wire can be used for building wiring, it is not the preferred choice. Solid wire is easier to terminate and route through walls and conduits, making it the standard for residential and commercial building wiring. Stranded wire is better suited for applications that require flexibility and resistance to vibration. -

Is solid wire always cheaper than stranded wire?

In general, solid wire is less expensive than stranded wire of the same gauge due to its simpler manufacturing process. However, the cost difference may vary depending on the specific wire specifications, such as insulation material, voltage rating, and supplier. -

Can I substitute stranded wire for solid wire in a circuit?

It is possible to substitute stranded wire for solid wire in a circuit, but it is important to consider the specific requirements of the application. Stranded wire may be a better choice if the circuit involves movement, flexing, or exposure to vibration. However, if the circuit requires stable connections and ease of termination, solid wire may be the preferred option. -

What is the skin effect, and how does it affect wire selection?

The skin effect is a phenomenon where high-frequency electrical current tends to flow more on the outer surface of a conductor rather than through its entire cross-section. This effect is more pronounced in solid wire compared to stranded wire. When selecting wire for high-frequency applications, such as RF systems or high-speed data transmission, stranded wire is often preferred due to its reduced skin effect and better signal integrity. -

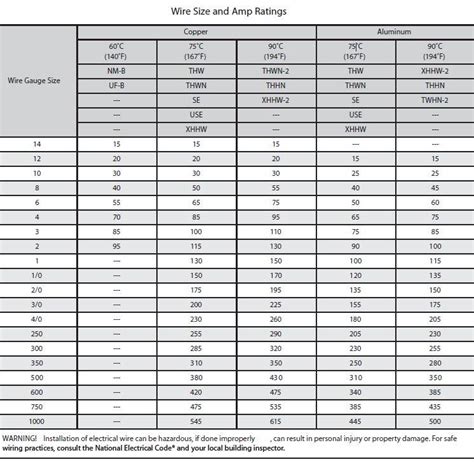

How do I choose the right wire gauge for my project?

Choosing the appropriate wire gauge depends on several factors, including the required current-carrying capacity, voltage drop, and mechanical strength. Thicker wire gauges (lower gauge numbers) can handle higher currents and have lower resistance, while thinner wire gauges (higher gauge numbers) are suitable for lower current applications and offer better flexibility. It is essential to consult wire ampacity charts and consider the specific requirements of your project to select the appropriate wire gauge.

Conclusion

Understanding the differences between stranded and solid wire is crucial for selecting the most suitable conductor for your electrical and electronic projects. Stranded wire excels in applications that demand flexibility, durability, and resistance to vibration, while solid wire is the preferred choice for stable connections, ease of termination, and cost-effectiveness.

By considering factors such as the intended application, environmental conditions, and signal frequency, you can make an informed decision on whether to use stranded or solid wire. Utilizing the appropriate wire type ensures optimal performance, reliability, and longevity of your electrical and electronic systems.

Remember to always adhere to relevant electrical codes, safety standards, and best practices when working with wire and electrical components. Consulting with experienced professionals or referring to trusted resources can provide further guidance and ensure the success of your projects.

With this comprehensive understanding of stranded and solid wire, you are now well-equipped to tackle your electrical and electronic endeavors with confidence, knowing that you have selected the most suitable conductor for the task at hand.

Leave a Reply