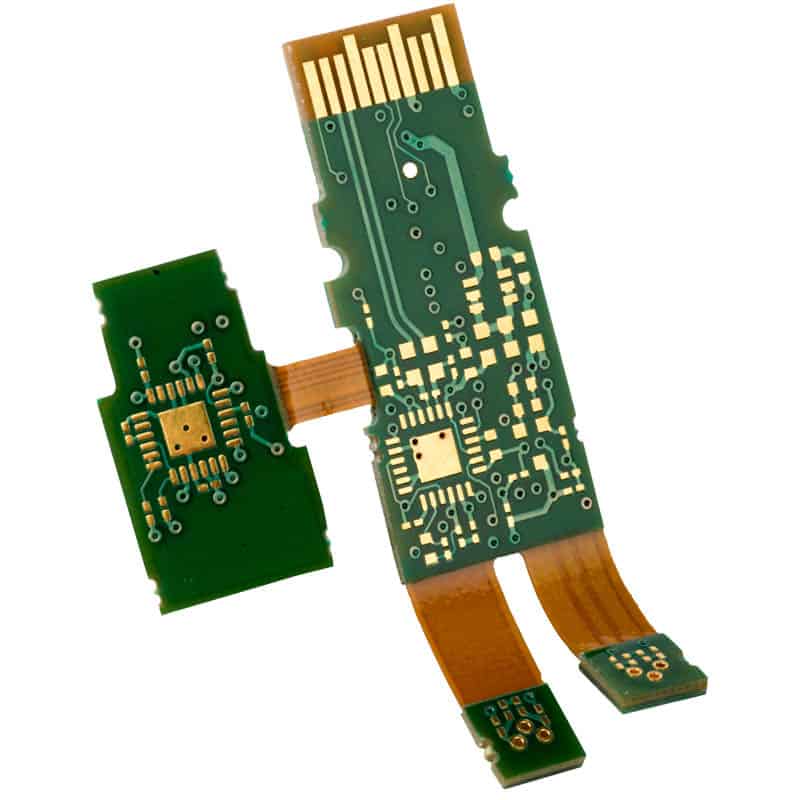

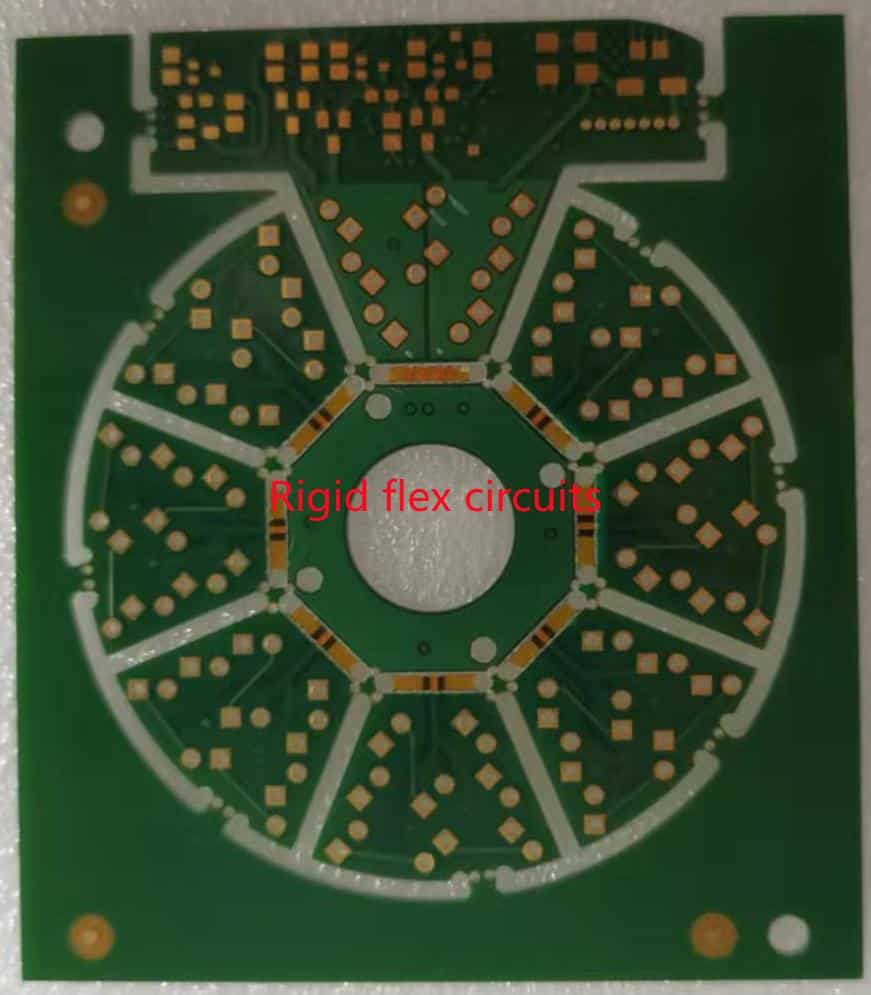

Rigid flex PCBs, also known as flex-rigid PCBs or rigid flex circuits, are printed circuit boards that contain both rigid and flexible substrates laminated together into a single structure. They provide design flexibility and reliability in a small footprint, making them ideal for many modern electronic devices. As rigid flex PCBs grow in popularity, it’s important for design engineers and procurement managers to understand how pricing is determined for this technology. This guide will examine the key factors that influence rigid flex PCB pricing and provide price ranges for different configurations.

What is a Rigid Flex PCB?

A rigid flex PCB consists of flexible circuits and rigid boards that are laminated together with adhesive. The rigid sections provide mechanical support and component mounting stability, while the flexible sections allow dynamic flexing, bending, and twisting. This enables the PCB to conform to different shapes and spaces.

Rigid flex PCBs are commonly used in the following applications:

- Consumer electronics – Cell phones, laptops, VR headsets

- Medical devices – Imaging systems, implants, wearables

- Industrial automation – Robotics, automation machinery

- Aerospace and defense – Avionics, weapon systems

Compared to rigid PCBs, rigid flex PCBs offer:

- Smaller footprint

- Dynamic flexing ability

- Enhanced reliability with fewer interconnects

- Design flexibility for complex layouts

Rigid Flex PCB Price Influencers

Several factors determine the final pricing of a rigid flex PCB from a manufacturer. Here are some of the major considerations:

1. Board Complexity

The number of conductive layers and the routing complexity have a direct impact on rigid flex PCB pricing. Simpler 2 or 4 layer designs are less expensive than designs with 6 or more layers. High density interconnects, blind/buried vias, and other advanced routing features also increase fabrication costs.

2. Board Size

In general, larger rigid flex PCB sizes are more expensive due to higher material costs. Smaller boards with tightly spaced traces often require additional processing steps, also driving up costs. Standard sizes from 100mm x 100mm to 457mm x 610mm tend to be the most cost effective.

3. Flexible Layer Design

The complexity and thickness of the flexible sections affect pricing. More complex flexible layers with tighter trace spacing and thinner flexible substrates increase costs. Common flexible thicknesses range from 25 um to 150 um.

4. Layer Count

More PCB layers allow for greater routing densities but also increase lamination time and materials. 4-6 layers are common for many rigid flex designs. More than 8 layers rapidly increases cost.

5. Materials

Base material selection (FR-4, polyimide, etc) impacts cost. More robust substrates like polyimide are more expensive than standard FR-4. Special materials like Rogers or Teflon are premium options.

6. Tolerances

Tighter tolerances require additional process controls and increase cost. Standard tolerances of ±0.1mm are suitable for many applications.

7. Bend Radii

Smaller bend radii require special flexible substrate materials and processes, increasing cost. Minimum bend radii range from 2mm to 10mm typically.

8. Stiffeners

Adding rigid stiffeners to maintain shape in dynamic sections adds materials and fabrication steps. Stiffener integration can increase cost 10-35%.

9. Finish

Special finishes like immersion silver, ENIG, and hard gold cost more than standard HASL finishes.

10. Testing

Extensive functional testing, inspection, and other quality assurance steps get added to the base cost.

11. Quantity

Higher order volumes distribute setup costs and offer economies of scale. Prototyping in low volumes is more expensive.

12. Location

Country and region of the PCB manufacturer impacts labor, materials, and equipment costs. Asia, Europe and North America have varied pricing.

Rigid Flex PCB Cost Estimates

With all the variables involved, it’s difficult to provide definitive pricing estimates. However, here are some typical rigid flex PCB price ranges for small to medium production volumes based on the design complexity:

| Rigid Flex PCB Type | Typical Price Range |

|---|---|

| 2 Layer, Simple Flex | $200 – $500 |

| 4 Layer, Moderate Flex | $450 – $900 |

| 6 Layer, Complex Flex | $750 – $1,500 |

| 8+ Layers, Multilayer Rigid & Flex | $1,500 – $4,500 |

Other considerations that could increase the costs:

- Tight tolerances below 0.15mm

- High layer counts over 8 layers

- Small bend radii below 5mm

- Advanced PCB finishes

- Dense HDI trace spacing

As you can see, pricing has a wide range based on the product requirements. When sourcing a rigid flex PCB supplier, it helps to get multiple quotes for your specific design to compare pricing. Be sure to clearly communicate all specifications to get an accurate cost estimate.

How to Reduce Rigid Flex PCB Costs

Here are some tips to lower your rigid flex PCB costs:

- Optimize the layout: Simplify routing, reduce layers, and design efficiently to minimize complexity. This has the biggest impact on cost.

- Build with standard materials: Use common rigid/flex materials and avoid exotic material options when possible.

- Relax tolerances: Allow looser tolerances if the design permits it, such as ±0.2mm instead of ±0.1mm.

- Combine boards: Manufacture multiple circuits together on larger panels when feasible to improve economies of scale.

- Standardize designs: Re-use proven rigid flex designs across product generations and limit customization.

- Work with experienced suppliers: Suppliers with optimized rigid flex processes provide cost-effective production.

- Go with qualified suppliers: Getting quotes from 2-3 qualified suppliers ensures competitive pricing.

- Produce in higher volumes: Higher order volumes distribute setup costs and offer better per unit pricing.

- Compare geographic options: Evaluate international manufacturing locations that offer competitive pricing.

Key Takeaways on Rigid Flex PCB Pricing

- Rigid flex PCB costs are driven by design complexity, size, layer count, density, and other specifications.

- Typical rigid flex PCB prices range from $200 to $4,500 based on the number of layers and routing complexity.

- Optimizing designs, choosing qualified suppliers, and ordering in higher volumes reduces rigid flex PCB costs.

- Getting multiple quotes from suppliers is recommended to compare pricing for a given rigid flex design.

Rigid flex PCB technology provides unique advantages over traditional PCBs for many electronic products. Understanding the key pricing factors enables designing high value rigid flex boards at affordable costs. With the right design expertise and supplier relationship, rigid flex PCBs can improve products and drive business growth.

Frequently Asked Questions about Rigid Flex PCB Pricing

Q: What is the main factor affecting the price of rigid flex PCBs?

A: The number of conductive layers and the routing complexity have the biggest impact on rigid flex PCB pricing. More complex designs with higher layer counts increase fabrication costs.

Q: How much does board size influence rigid flex PCB cost?

A: Board size has a moderate effect on cost. Larger boards use more base materials, but shrinking size can increase complexity. Standard sizes from 100mm – 460mm tend to be most cost-effective.

Q: Do special finishes like ENIG cost more for rigid flex PCBs?

A: Yes, finishes like immersion silver, ENIG, and hard gold do add cost premiums compared to standard HASL because of additional materials and process steps.

Q: How can I estimate the cost of a rigid flex design I’m working on?

A: Get quotes from 2-3 PCB suppliers to compare pricing based on your specific design requirements. Provide full details on layers, size, flex complexity, and other specs.

Q: Should I expect better pricing for higher order quantities?

A: Yes, producing rigid flex PCBs in volumes of 500+ units will provide improved economies of scale compared to lower prototyping volumes. Discuss pricing tiers with your supplier.

Leave a Reply