Understanding PCB Turnkey Services

What is a PCB Turnkey Service?

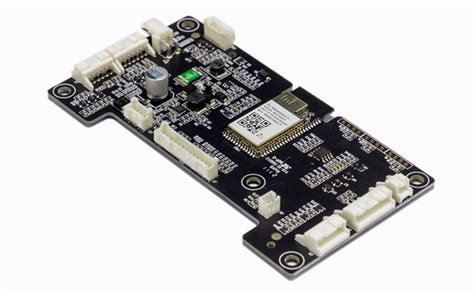

A PCB turnkey service is an end-to-end solution for PCB manufacturing, where the service provider handles all aspects of the process, including:

- PCB Design

- PCB Fabrication

- Component Sourcing

- PCB Assembly

- Testing and Quality Control

By outsourcing your PCB manufacturing to a turnkey service provider, you can streamline your production process, reduce costs, and ensure consistent quality.

Benefits of Using a PCB Turnkey Service

-

Time Savings: By entrusting your PCB manufacturing to a turnkey service provider, you can focus on other aspects of your project while the experts handle the PCB production process.

-

Cost-Effectiveness: PCB turnkey service providers often have established relationships with component suppliers and can leverage economies of scale to offer competitive pricing.

-

Quality Assurance: Reputable PCB turnkey service providers adhere to strict quality control measures to ensure that your PCBs meet the highest standards of reliability and performance.

-

Expertise and Support: PCB turnkey service providers have experienced engineers and technicians who can offer valuable insights and support throughout the manufacturing process.

Factors to Consider When Choosing a PCB Turnkey Service Provider

1. Manufacturing Capabilities

When evaluating PCB turnkey service providers, it’s essential to consider their manufacturing capabilities. Some key aspects to look for include:

-

PCB Complexity: Can the provider handle the complexity of your PCB design, including multi-layer boards, high-density interconnects (HDI), and advanced materials?

-

Technology and Equipment: Does the provider invest in state-of-the-art manufacturing technology and equipment to ensure the highest quality standards?

-

Production Capacity: Can the provider accommodate your production volume requirements, whether you need small prototype runs or large-scale production?

2. Quality Control and Certifications

Quality control is a critical aspect of PCB manufacturing. Look for a PCB turnkey service provider that has:

-

Rigorous Quality Control Processes: The provider should have well-defined quality control procedures in place, including incoming material inspection, in-process checks, and final product testing.

-

Industry Certifications: Certifications such as ISO 9001, IPC, and UL demonstrate a provider’s commitment to quality and adherence to industry standards.

-

Traceability and Documentation: The provider should maintain detailed documentation and traceability records to ensure accountability and facilitate problem resolution.

3. Customer Support and Communication

Effective communication and customer support are essential for a successful PCB manufacturing partnership. Consider the following:

-

Responsive Communication: The provider should be responsive to your inquiries and keep you informed throughout the manufacturing process.

-

Technical Support: Look for a provider that offers expert technical support to help you navigate any challenges or questions that may arise.

-

Flexibility and Customization: The provider should be willing to accommodate your specific requirements and offer customized solutions to meet your needs.

4. Lead Time and Delivery

Lead time and on-time delivery are critical factors in PCB manufacturing. Consider the following:

-

Production Lead Time: Look for a provider that can offer competitive lead times without compromising quality.

-

On-Time Delivery: The provider should have a track record of meeting delivery deadlines consistently.

-

Shipping and Logistics: Evaluate the provider’s shipping and logistics capabilities to ensure that your PCBs can be delivered to your location efficiently and securely.

5. Cost and Value

While cost is an important consideration, it should not be the sole deciding factor when choosing a PCB turnkey service provider. Consider the following:

-

Competitive Pricing: Look for a provider that offers competitive pricing without compromising quality or service.

-

Value-Added Services: Consider providers that offer additional value-added services, such as design support, component sourcing, and supply chain management.

-

Total Cost of Ownership: Evaluate the total cost of ownership, including not only the direct manufacturing costs but also the indirect costs associated with quality, reliability, and support.

PCB Manufacturing Process Overview

To better understand the role of a PCB turnkey service provider, let’s briefly overview the PCB manufacturing process.

-

PCB Design: The process begins with the creation of a PCB design using electronic design automation (EDA) software. The design includes the schematic, layout, and bill of materials (BOM).

-

PCB Fabrication: Once the design is finalized, the PCB fabrication process begins. This involves creating the bare PCB board through a series of steps, including:

- Substrate preparation

- Copper foil lamination

- Drilling and plating

- Etching and resist stripping

- Solder mask application

-

Silkscreen printing

-

Component Sourcing: The PCB turnkey service provider sources the components required for the PCB assembly based on the BOM provided by the customer.

-

PCB Assembly: The fabricated PCB and sourced components are then brought together in the PCB assembly process. This typically involves:

- Solder paste application

- Component placement

- Reflow soldering

-

Inspection and rework (if necessary)

-

Testing and Quality Control: The assembled PCBs undergo rigorous testing and quality control procedures to ensure they meet the required specifications and performance standards. This may include:

- Automated optical inspection (AOI)

- X-ray inspection

- Functional testing

-

Burn-in testing

-

Packaging and Shipping: Once the PCBs have passed all quality checks, they are packaged and shipped to the customer according to their specified requirements.

Top PCB Turnkey Service Providers

To help you start your search for the best PCB turnkey service provider, here are some of the top companies in the industry:

-

Jabil Circuit: Jabil is a global manufacturing services company that offers comprehensive PCB turnkey services, including design, fabrication, assembly, and testing. They have a strong presence in various industries, including automotive, healthcare, and telecommunications.

-

Foxconn: Foxconn is a Taiwanese electronics manufacturing company that provides PCB turnkey services to a wide range of customers. They are known for their large-scale production capabilities and have facilities in multiple countries.

-

Sanmina: Sanmina is a US-based electronics manufacturing services company that offers PCB turnkey services, including design, fabrication, assembly, and testing. They have a strong focus on high-reliability applications, such as medical devices and aerospace.

-

Benchmark Electronics: Benchmark Electronics is a global provider of electronics manufacturing services, including PCB turnkey solutions. They have expertise in various industries, such as industrial, telecommunications, and computing.

-

Celestica: Celestica is a Canadian electronics manufacturing services company that offers PCB turnkey services, including design, fabrication, assembly, and testing. They have a strong presence in the aerospace and defense, healthcare, and energy sectors.

Frequently Asked Questions (FAQ)

-

What is the minimum order quantity (MOQ) for PCB turnkey services?

The MOQ varies depending on the PCB turnkey service provider and the specific requirements of your project. Some providers may offer low-volume production runs for prototyping, while others may require higher MOQs for mass production. It’s best to discuss your specific needs with potential providers to determine their MOQ policies. -

How long does the PCB turnkey manufacturing process typically take?

The lead time for PCB turnkey manufacturing depends on various factors, such as the complexity of the PCB design, the availability of components, and the production volume. On average, the process can take anywhere from a few days to several weeks. Many PCB turnkey service providers offer expedited services for time-sensitive projects, but this may come at an additional cost. -

Can PCB turnkey service providers handle both prototype and mass production runs?

Yes, most reputable PCB turnkey service providers can accommodate both prototype and mass production runs. However, the specific capabilities and minimum order quantities may vary between providers. It’s essential to discuss your project requirements with potential providers to ensure they can meet your needs for both prototype and mass production. -

How can I ensure the quality of the PCBs produced by a turnkey service provider?

To ensure the quality of your PCBs, choose a PCB turnkey service provider with a proven track record of quality and reliability. Look for providers with industry certifications, such as ISO 9001 and IPC, which demonstrate their commitment to quality management systems and adherence to industry standards. Additionally, ask about their quality control processes, testing procedures, and documentation practices to ensure they meet your quality expectations. -

What should I do if I encounter issues with the PCBs produced by a turnkey service provider?

If you encounter issues with the PCBs produced by a turnkey service provider, the first step is to contact their customer support team and provide detailed information about the problem. Most reputable providers have well-established processes for handling customer complaints and will work with you to resolve the issue promptly. In some cases, they may offer replacements, rework, or refunds, depending on the nature of the problem and the terms of your agreement.

Conclusion

Choosing the right PCB turnkey service provider is essential for ensuring the success of your electronics project. By considering factors such as manufacturing capabilities, quality control, customer support, lead time, and cost, you can select a provider that best meets your specific needs and requirements.

Remember to thoroughly evaluate potential providers, ask for references, and discuss your project in detail to ensure a successful partnership. With the right PCB turnkey service provider on your side, you can streamline your production process, reduce costs, and bring your innovative electronic products to market faster and more efficiently.

Leave a Reply