What is a PCB Transformer?

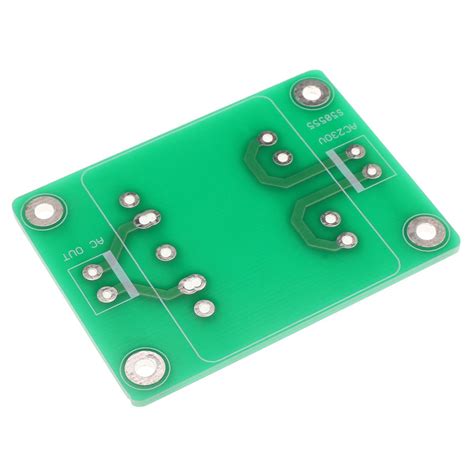

A PCB transformer, short for Printed Circuit Board transformer, is a type of transformer that is specifically designed to be mounted directly onto a printed circuit board (PCB). Unlike conventional transformers that are typically bulky and require separate mounting arrangements, PCB transformers are compact, lightweight, and can be easily integrated into electronic circuits.

PCB transformers are widely used in various electronic applications, particularly in low-power devices such as power supplies, audio equipment, and telecommunications systems. They play a crucial role in providing electrical isolation, voltage step-up or step-down, and impedance matching between different stages of a circuit.

Key Features of PCB Transformers

- Compact size: PCB transformers are designed to have a small footprint, allowing them to fit easily onto crowded PCBs.

- Surface-mount design: Most PCB transformers are surface-mount devices (SMD), which means they can be directly soldered onto the PCB without the need for through-hole mounting.

- High efficiency: Despite their small size, PCB transformers offer high efficiency in power conversion and signal coupling.

- Electrical isolation: PCB transformers provide galvanic isolation between different sections of a circuit, preventing unwanted electrical interference and ensuring safety.

- Wide frequency range: PCB transformers can operate over a wide range of frequencies, from a few hertz to several megahertz, depending on their design and application.

Types of PCB Transformers

PCB transformers come in various types, each designed for specific applications and requirements. Some common types include:

1. Power Transformers

Power transformers are used to step up or step down the voltage level in a power supply circuit. They are typically designed to handle higher power levels compared to other types of PCB transformers.

2. Pulse Transformers

Pulse transformers are used in applications that require the transmission of short, high-energy electrical pulses. They are commonly found in switching power supplies, telecommunications systems, and high-speed digital circuits.

3. Audio Transformers

Audio transformers are designed to couple audio signals between different stages of an audio circuit while providing electrical isolation and impedance matching. They are widely used in audio equipment such as microphone preamplifiers, mixers, and amplifiers.

4. RF Transformers

RF (radio frequency) transformers are used in high-frequency applications such as wireless communication systems, RF power amplifiers, and antenna matching networks. They are designed to operate at frequencies ranging from a few megahertz to several gigahertz.

Applications of PCB Transformers

PCB transformers find applications in a wide range of electronic devices and systems. Some common applications include:

1. Power Supplies

PCB transformers are extensively used in power supply circuits to step up or step down the voltage level according to the requirements of the connected load. They provide isolation between the primary and secondary sides of the power supply, ensuring safety and preventing ground loops.

2. Audio Equipment

In audio equipment, PCB transformers are used for various purposes, such as:

– Coupling audio signals between different stages while providing isolation

– Matching the impedance between the source and the load

– Balancing unbalanced audio signals

– Splitting audio signals for distribution

3. Telecommunications

PCB transformers play a vital role in telecommunications systems, where they are used for:

– Coupling telephone lines to electronic circuits

– Providing isolation between the telephone line and the equipment

– Matching the impedance of the telephone line to the electronic circuit

– Suppressing common-mode noise and interference

4. Measurement and Control Systems

In measurement and control systems, PCB transformers are used for:

– Isolating sensitive measurement circuits from the main power supply

– Converting voltage levels for sensor excitation and signal conditioning

– Providing isolation between control signals and power circuits

5. Automotive Electronics

PCB transformers are increasingly used in automotive electronic systems, such as:

– DC-DC converters for power supply regulation

– Isolation transformers for electric vehicle charging systems

– Signal isolation in automotive control units

Selecting the Right PCB Transformer

When choosing a PCB transformer for a specific application, several factors need to be considered:

- Power rating: The transformer should be capable of handling the required power level without overheating or saturating.

- Voltage ratio: The turns ratio of the transformer should provide the desired voltage step-up or step-down ratio.

- Frequency range: The transformer should be designed to operate efficiently within the required frequency range.

- Isolation voltage: The transformer should provide sufficient isolation voltage between the primary and secondary windings to ensure safety and prevent interference.

- Mounting type: The transformer should be compatible with the PCB layout and mounting requirements (surface-mount or through-hole).

- Size and weight: The transformer should fit within the available space on the PCB and meet any weight constraints.

- Environmental factors: The transformer should be able to withstand the expected environmental conditions, such as temperature, humidity, and vibration.

PCB Transformer Manufacturing Process

The manufacturing process of PCB transformers involves several steps:

- Core selection: The appropriate core material (ferrite, iron powder, etc.) and shape (toroidal, E-I, etc.) are selected based on the desired performance characteristics.

- Winding: The primary and secondary windings are wound around the core using enameled copper wire or specialized winding machines.

- Insulation: The windings are insulated from each other and the core using insulating materials such as paper, tape, or plastic.

- Termination: The transformer leads are terminated using pins, pads, or surface-mount terminals for easy connection to the PCB.

- Encapsulation: The transformer assembly is encapsulated in a protective housing or coating to provide mechanical stability and environmental protection.

- Testing: The finished transformers undergo various electrical and mechanical tests to ensure they meet the specified performance and quality standards.

Advantages of Using PCB Transformers

PCB transformers offer several advantages over conventional transformers:

- Space savings: The compact size of PCB transformers allows for more efficient use of PCB space, enabling the design of smaller and more portable electronic devices.

- Ease of assembly: Surface-mount PCB transformers can be easily incorporated into automated PCB assembly processes, reducing manufacturing time and costs.

- Improved reliability: The integrated design of PCB transformers eliminates the need for external wiring and connections, reducing the risk of failures and improving overall reliability.

- Reduced EMI: The close coupling between the windings and the use of shielding techniques help reduce electromagnetic interference (EMI) in PCB transformers.

- Customization: PCB transformers can be custom-designed to meet specific application requirements, such as unique voltage ratios, power ratings, and form factors.

Challenges and Considerations

While PCB transformers offer many benefits, there are also some challenges and considerations to keep in mind:

- Limited power handling: Due to their small size, PCB transformers are generally limited in their power handling capacity compared to larger, conventional transformers.

- Thermal management: The compact design of PCB transformers can make heat dissipation more challenging, requiring careful thermal management to prevent overheating.

- Saturation: The small core size of PCB transformers makes them more susceptible to saturation at high currents, which can lead to distortion and loss of efficiency.

- High-frequency losses: At high frequencies, the windings of PCB transformers can experience increased losses due to skin effect and proximity effect, reducing overall efficiency.

- Mechanical stress: PCB transformers are subject to mechanical stress during the PCB assembly process, such as soldering and reflow, which can cause damage if not properly designed and handled.

Future Trends in PCB Transformer Technology

As electronic devices continue to become smaller, more powerful, and more efficient, PCB transformer technology is evolving to keep pace with these trends. Some of the future developments in PCB transformer technology include:

- Advanced materials: The use of advanced magnetic materials, such as nanocrystalline alloys and high-permeability ferrites, can help improve the performance and efficiency of PCB transformers.

- 3D printing: The adoption of 3D printing techniques for the fabrication of PCB transformers can enable the creation of complex geometries and customized designs, leading to improved performance and flexibility.

- Integration with other components: The integration of PCB transformers with other passive components, such as capacitors and inductors, can help reduce the overall component count and improve circuit performance.

- High-frequency designs: The development of specialized PCB transformers for high-frequency applications, such as 5G wireless communication and high-speed digital systems, will become increasingly important.

- Energy harvesting: PCB transformers can play a role in energy harvesting systems, where they can be used to step up the low voltages generated by energy harvesting devices to usable levels.

Frequently Asked Questions (FAQ)

1. What is the difference between a PCB transformer and a conventional transformer?

A PCB transformer is specifically designed to be mounted directly onto a printed circuit board, while a conventional transformer is a standalone component that requires separate mounting arrangements. PCB transformers are typically smaller, lighter, and more easily integrated into electronic circuits compared to conventional transformers.

2. Can PCB transformers handle high power levels?

PCB transformers are generally limited in their power handling capacity due to their small size. They are best suited for low-power applications, typically ranging from a few milliwatts to several watts. For higher power levels, conventional transformers or specialized high-power PCB transformers may be required.

3. Are PCB transformers more expensive than conventional transformers?

The cost of PCB transformers depends on various factors, such as the type, size, and specifications of the transformer. In general, PCB transformers can be more expensive than conventional transformers due to their specialized design and manufacturing process. However, the overall cost savings in terms of PCB space, assembly time, and reliability can often offset the higher initial cost of PCB transformers.

4. How do I select the appropriate PCB transformer for my application?

When selecting a PCB transformer, consider factors such as the required power rating, voltage ratio, frequency range, isolation voltage, mounting type, size, and environmental conditions. Consult the transformer manufacturer’s datasheets and application notes to determine the most suitable transformer for your specific requirements.

5. Can PCB transformers be custom-designed for specific applications?

Yes, PCB transformers can be custom-designed to meet specific application requirements. Transformer manufacturers often offer design services to help customers develop transformers with unique voltage ratios, power ratings, and form factors. Custom-designed PCB transformers can provide optimized performance and a perfect fit for the intended application.

Conclusion

PCB transformers are essential components in a wide range of electronic applications, offering advantages such as space savings, ease of assembly, improved reliability, and reduced EMI. By understanding the types, applications, and selection criteria of PCB transformers, designers can effectively incorporate these components into their electronic circuits.

As electronic devices continue to evolve, so too will PCB transformer technology. Advanced materials, 3D printing, integration with other components, high-frequency designs, and energy harvesting are just some of the trends shaping the future of PCB transformers.

By staying informed about the latest developments in PCB transformer technology and working closely with transformer manufacturers, designers can unlock new possibilities for their electronic products and stay ahead of the curve in this rapidly evolving field.

Leave a Reply