Introduction to PCB CNC Machines

PCB CNC machines are high-precision computer-controlled machines used for the manufacturing of printed circuit boards (PCBs). These machines are essential in the electronics industry as they enable the rapid and accurate production of complex PCB designs. PCB CNC machines utilize advanced technology to drill, route, and mill PCBs, ensuring high-quality results and faster turnaround times compared to traditional manual methods.

Key Components of PCB CNC Machines

- Spindle: The spindle is the rotating tool holder that holds the drilling or milling bits. It is driven by a high-speed motor and is capable of precise movements in multiple axes.

- Gantry: The gantry is the movable structure that supports the spindle and allows it to move along the X, Y, and Z axes.

- Control System: The control system consists of a computer and software that interprets the PCB design files and controls the movement of the spindle and gantry.

- Vacuum Table: The vacuum table holds the PCB substrate securely in place during the machining process.

- Dust Collection System: The dust collection system removes debris generated during the drilling and milling processes, keeping the work area clean and preventing damage to the machine.

Advantages of PCB CNC Machines

Increased Accuracy and Precision

PCB CNC machines offer unparalleled accuracy and precision compared to manual PCB manufacturing methods. These machines can achieve tolerances as low as ±0.001 inches, ensuring that the PCB design is faithfully reproduced. The high level of accuracy is essential for modern electronics, where even the slightest deviation can lead to device malfunction.

Faster Production Times

CNC machines significantly reduce the time required to manufacture PCBs. Once the PCB design is loaded into the machine’s control system, the machine can work continuously with minimal human intervention. This automation allows for faster production times, enabling manufacturers to meet tight deadlines and increase their output.

Consistency and Repeatability

PCB CNC machines ensure consistent results across multiple production runs. By eliminating human error and variability, these machines can produce identical PCBs time after time. This consistency is crucial for maintaining product quality and reliability.

Versatility in PCB Design

CNC machines can handle a wide range of PCB designs, from simple single-layer boards to complex multi-layer designs with fine pitch components. The machines’ ability to process various materials, such as FR-4, aluminum, and flexible substrates, further enhances their versatility.

Types of PCB CNC Machines

Drilling Machines

PCB Drilling machines are used to create holes in the PCB substrate for component placement and via creation. These machines use high-speed spindles and small diameter drill bits to create precise holes in the PCB. Modern drilling machines can drill thousands of holes per minute, greatly reducing the time required for this critical step in PCB manufacturing.

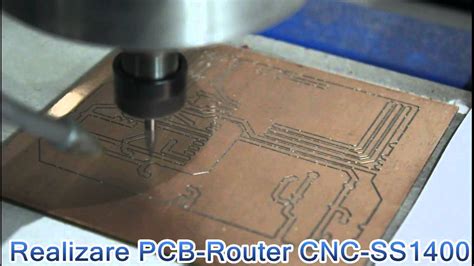

Routing Machines

PCB routing machines are used to cut out the individual PCBs from a larger panel and to create slots, cutouts, and other features in the PCB. These machines use a variety of cutting tools, such as end mills and routers, to achieve the desired shape and size of the PCB.

Milling Machines

PCB Milling machines are used for the removal of excess copper from the PCB substrate. This process, known as isolation milling, creates the necessary electrical isolation between different copper traces on the PCB. Milling machines can also be used for creating PCB Prototypes and small-batch production runs.

PCB CNC Machine Software

The software used to control PCB CNC machines plays a crucial role in the manufacturing process. The software takes the PCB design files, typically in Gerber or ODB++ format, and generates the necessary machine code (G-code) to control the movement of the spindle and gantry.

There are several popular PCB CNC machine software options available, including:

- Altium Designer

- KiCad

- Eagle

- Fusion360

- Mastercam

These software packages offer various features and capabilities, such as design rule checking, 3D modeling, and simulation, to help optimize the PCB design and manufacturing process.

Maintenance and Troubleshooting

Regular Maintenance

To ensure optimal performance and longevity of PCB CNC machines, regular maintenance is essential. This includes:

- Lubricating moving parts

- Checking and replacing worn or damaged tools

- Cleaning the machine and work area

- Calibrating the machine to maintain accuracy

Common Issues and Troubleshooting

Despite regular maintenance, PCB CNC machines may encounter issues that affect their performance. Some common problems include:

- Tool breakage: Replace broken tools and adjust feed rates and spindle speeds to prevent future breakages.

- Inaccurate positioning: Recalibrate the machine and check for loose or worn components in the gantry and spindle assembly.

- Poor surface finish: Adjust the cutting parameters, such as feed rate and depth of cut, and ensure that the tools are sharp and in good condition.

- Vacuum table not holding the PCB: Check for leaks in the vacuum system and ensure that the PCB is properly positioned on the table.

| Problem | Possible Cause | Solution |

|---|---|---|

| Tool breakage | Excessive feed rate or spindle speed | Adjust feed rates and spindle speeds |

| Inaccurate positioning | Loose or worn components | Recalibrate the machine and check for loose or worn components |

| Poor surface finish | Incorrect cutting parameters | Adjust cutting parameters and ensure tools are sharp |

| Vacuum table not holding PCB | Leaks in the vacuum system | Check for leaks and ensure PCB is properly positioned |

Future Trends in PCB CNC Machines

As the electronics industry continues to evolve, so too will PCB CNC machines. Some of the future trends in PCB CNC technology include:

- Increased automation: The integration of robotics and artificial intelligence will further automate the PCB manufacturing process, reducing the need for human intervention and increasing efficiency.

- Miniaturization: As electronic devices become smaller, PCB CNC machines will need to adapt to handle smaller components and finer pitch sizes.

- Additive manufacturing: The incorporation of 3D printing technology into PCB CNC machines will enable the creation of complex, three-dimensional PCB structures.

- Smart factories: PCB CNC machines will be connected to the Internet of Things (IoT), allowing for real-time monitoring, data collection, and predictive maintenance.

Frequently Asked Questions (FAQ)

1. What is the difference between a PCB CNC machine and a 3D printer?

While both PCB CNC machines and 3D printers are computer-controlled machines, they serve different purposes. PCB CNC machines are used for subtractive manufacturing, where material is removed from a PCB substrate to create the desired features. 3D printers, on the other hand, are used for additive manufacturing, where material is added layer by layer to create a three-dimensional object.

2. Can PCB CNC machines handle multi-layer PCBs?

Yes, modern PCB CNC machines are capable of handling multi-layer PCBs. The machines can drill through multiple layers and create the necessary vias and interconnections between the layers.

3. What is the typical accuracy of a PCB CNC machine?

The accuracy of a PCB CNC machine depends on the specific model and configuration, but most machines can achieve tolerances of ±0.001 inches or better.

4. How long does it take to set up a PCB CNC machine for a new job?

The setup time for a new job on a PCB CNC machine varies depending on the complexity of the PCB design and the machine’s configuration. On average, setup times can range from 30 minutes to several hours.

5. What is the learning curve for operating a PCB CNC machine?

Operating a PCB CNC machine requires a combination of technical skills and knowledge of PCB design and manufacturing processes. The learning curve can vary depending on the individual’s background and experience, but most operators require several weeks to several months of training to become proficient.

Conclusion

PCB CNC machines have revolutionized the electronics industry by enabling the rapid and accurate production of complex PCB designs. These high-tech machines offer numerous advantages over traditional manual methods, including increased accuracy, faster production times, and consistent results.

As the demand for advanced electronic devices continues to grow, PCB CNC machines will play an increasingly crucial role in meeting the industry’s needs. By understanding the capabilities, maintenance requirements, and future trends of these machines, manufacturers can optimize their PCB production processes and stay competitive in the ever-evolving electronics landscape.

Leave a Reply