What is PCB Impedance?

PCB impedance refers to the opposition to the flow of electrical current in a printed circuit board (PCB). It is a critical factor in ensuring the integrity and reliability of high-speed digital signals and high-frequency analog signals in PCB designs. Controlling PCB impedance is essential for maintaining signal quality, minimizing signal reflections, and reducing electromagnetic interference (EMI).

Types of PCB Impedance

There are two main types of PCB impedance:

-

Characteristic Impedance (Z0): This is the impedance of a transmission line on a PCB, which is determined by the geometry and materials of the PCB. It is important to match the characteristic impedance of the transmission line to the impedance of the source and load to minimize signal reflections.

-

Differential Impedance (Zdiff): This is the impedance between two balanced transmission lines on a PCB, such as in differential signaling. Differential impedance is important for maintaining signal integrity and reducing crosstalk between adjacent traces.

Factors Affecting PCB Impedance

Several factors can affect PCB impedance, including:

1. PCB Material Properties

The dielectric constant (Dk) and dissipation factor (Df) of the PCB material play a significant role in determining the impedance of the transmission lines. Materials with higher Dk values, such as FR-4, will result in lower impedance compared to materials with lower Dk values, such as Rogers RO4003.

| Material | Dielectric Constant (Dk) | Dissipation Factor (Df) |

|---|---|---|

| FR-4 | 4.2 – 4.5 | 0.02 – 0.03 |

| Rogers 4350B | 3.48 | 0.0037 |

| Isola I-Tera MT40 | 3.45 | 0.0031 |

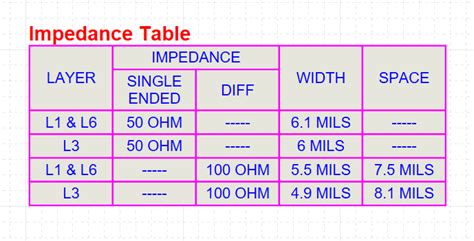

2. Trace Geometry

The width, thickness, and spacing of the traces on a PCB can significantly impact the impedance. Wider traces will have lower impedance, while narrower traces will have higher impedance. The thickness of the copper traces also affects impedance, with thicker traces having lower impedance.

3. PCB Stack-Up

The arrangement of the layers in a PCB, known as the stack-up, can influence the impedance of the transmission lines. The distance between the signal layer and the reference plane (ground or power) affects the impedance, with closer spacing resulting in lower impedance.

4. Via Design

Vias, which are used to connect traces between layers on a PCB, can introduce discontinuities in the impedance of the transmission lines. The size, shape, and placement of vias can affect the impedance and cause signal reflections.

PCB Impedance Control Techniques

To ensure proper impedance control in PCB designs, several techniques can be employed:

1. Impedance Matching

Matching the impedance of the transmission lines to the impedance of the source and load is crucial for minimizing signal reflections. This can be achieved by adjusting the trace width, thickness, and spacing, as well as selecting appropriate PCB materials.

2. Differential Pair Routing

When routing differential pairs, it is important to maintain a consistent spacing between the traces and to route them as close together as possible. This helps to maintain the differential impedance and reduces crosstalk between adjacent traces.

3. Ground Plane Stitching

Using ground plane stitching, which involves placing vias at regular intervals to connect the ground planes on different layers, can help to maintain a consistent reference plane and reduce impedance discontinuities.

4. Impedance Calculation and Simulation

Using impedance calculation tools and simulation software can help designers determine the appropriate trace geometries and spacing to achieve the desired impedance. These tools take into account the PCB material properties, stack-up, and trace dimensions to provide accurate impedance predictions.

PCB Impedance Testing and Measurement

To verify that the impedance of a PCB meets the design requirements, testing and measurement techniques can be employed:

1. Time Domain Reflectometry (TDR)

TDR is a technique that uses high-speed pulses to measure the impedance of a transmission line. By analyzing the reflections of the pulse, the impedance profile of the transmission line can be determined. TDR is useful for identifying impedance discontinuities and mismatches.

2. Vector Network Analyzer (VNA)

A VNA is an instrument that measures the scattering parameters (S-parameters) of a transmission line. By analyzing the S-parameters, the impedance of the transmission line can be determined. VNAs are useful for measuring the frequency-dependent behavior of the impedance.

FAQ

-

What is the importance of PCB impedance control?

PCB impedance control is essential for ensuring signal integrity, minimizing signal reflections, and reducing electromagnetic interference (EMI) in high-speed digital and high-frequency analog circuits. -

What are the main types of PCB impedance?

The two main types of PCB impedance are characteristic impedance (Z0), which is the impedance of a single transmission line, and differential impedance (Zdiff), which is the impedance between two balanced transmission lines. -

How does the choice of PCB material affect impedance?

The dielectric constant (Dk) and dissipation factor (Df) of the PCB material influence the impedance of the transmission lines. Materials with higher Dk values, such as FR-4, result in lower impedance compared to materials with lower Dk values, such as Rogers RO4003. -

What are some techniques for controlling PCB impedance?

Techniques for controlling PCB impedance include impedance matching, differential pair routing, ground plane stitching, and using impedance calculation and simulation tools. -

How can PCB impedance be tested and measured?

PCB impedance can be tested and measured using techniques such as Time Domain Reflectometry (TDR) and Vector Network Analyzer (VNA). TDR is useful for identifying impedance discontinuities and mismatches, while VNA is used for measuring the frequency-dependent behavior of the impedance.

Conclusion

PCB impedance control is a critical aspect of designing high-speed digital and high-frequency analog circuits. By understanding the factors that affect PCB impedance, such as material properties, trace geometry, and stack-up, designers can employ various techniques to ensure proper impedance control. These techniques include impedance matching, differential pair routing, ground plane stitching, and using impedance calculation and simulation tools.

To verify that the impedance of a PCB meets the design requirements, testing and measurement techniques such as Time Domain Reflectometry (TDR) and Vector Network Analyzer (VNA) can be used. By carefully controlling PCB impedance, designers can ensure signal integrity, minimize signal reflections, and reduce electromagnetic interference, resulting in more reliable and robust PCB designs.

Leave a Reply