What is a PCB File?

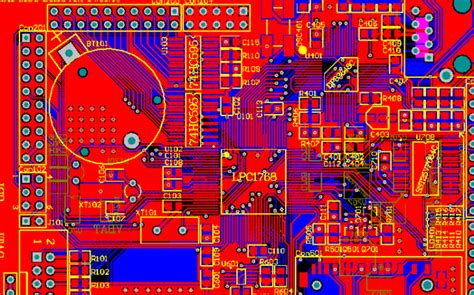

A PCB file, short for Printed Circuit Board file, is a digital file format used to store the design data for a printed circuit board. PCB files contain all the information needed to manufacture a physical PCB, including the board layout, component placement, routing, drill holes, copper traces, silkscreen, solder mask, and more.

PCB files are created using specialized PCB design software like Altium Designer, OrCAD, KiCad, Eagle, etc. The PCB design process involves capturing the schematic, laying out the board, routing traces to connect components, and generating manufacturing files.

There are several different PCB file formats, each with its own file extension and characteristics:

| File Format | Extension | Description |

|---|---|---|

| Gerber | .gbr | Industry standard format for PCB manufacturing. Includes copper layers, solder mask, silkscreen, drill data as separate files. |

| ODB++ | .tgz | Open database format that packages all manufacturing data into a single compressed file. Gaining popularity. |

| IPC-2581 | .xml | Intelligent data format that includes stackup, netlist, BOM. Enables bidirectional data exchange. |

| STEP | .stp | 3D CAD format used for mechanical integration of the PCB. |

| Portable document format useful for documentation and review. Not used directly for manufacturing. |

The choice of which PCB file format(s) to use depends on the capabilities of your PCB design tool and the requirements of your PCB manufacturer. Gerber is the most widely supported format, but more intelligent formats like ODB++ and IPC-2581 are becoming increasingly common.

Why Are PCB Files Important?

PCB files are critical because they contain all the data required to fabricate and assemble the physical printed circuit board. The accuracy and completeness of the PCB file directly impacts the manufacturability, functionality, reliability and cost of the end product.

Some key reasons why PCB files are so important:

-

Manufacturing: PCB manufacturers need the PCB files to fabricate the bare board and assemble components onto it. Missing or incorrect data in the PCB file can cause delays, scrap, and added costs.

-

Collaboration: PCB files enable different teams (e.g. design, manufacturing, test) and supply chain partners to exchange design data and collaborate effectively. Standardized formats allow interoperability between tools.

-

Revision Control: PCB files provide a way to track changes and revisions throughout the product lifecycle. Proper revision control of PCB files is essential for managing ECOs (engineering change orders).

-

Reuse: PCB files facilitate design reuse by capturing the full product definition in a reusable format. Portions of the design or the entire board layout can be imported into new designs.

-

Compliance: Some industries have specific requirements around data exchange and archiving. Using standard PCB file formats helps to meet ITAR, JEDEC, and other compliance obligations.

In the next sections, we’ll dive deeper into the structure and content of different PCB file formats, and best practices for working with them effectively.

Anatomy of a Gerber PCB File

Gerber is the most common PCB file format, so it’s important to understand its structure and contents. A typical Gerber PCB file set consists of several individual files, each representing a different layer or function of the board:

| File Extension | Layer/Function |

|---|---|

| .GTL | Top copper layer |

| .GBL | Bottom copper layer |

| .GTO | Top silkscreen (overlay) |

| .GBO | Bottom silkscreen |

| .GTP | Top solder paste |

| .GBP | Bottom solder paste |

| .GTS | Top solder mask |

| .GBS | Bottom solder mask |

| .TXT | Drill data |

| .GKO | Board outline |

Each Gerber file uses a vector image format (RS-274X) to describe the geometry of copper traces, pads, and other features as a series of coordinates and apertures. A separate aperture list file (.rep) defines the shape and size of each aperture used.

Here’s a snippet of what Gerber data looks like:

G04 EAGLE Gerber RS-274X export*

%ASAXBY*%

%FSLAX34Y34*%

%MOIN*%

%ADD10C,0.0100*%

%ADD11C,0.0080*%

G01*

G75*

%LPD*%

D10*

X0Y0D02*

X5905512Y0D01*

X5905512Y2027559D01*

D11*

X5905512Y2027559D02*

X5905512Y5905512D01*

X0Y5905512D01*

...

The Gerber format has some limitations, such as no netlist information and the need to manage multiple files for each board. However, it remains widely used due to its simplicity and compatibility with virtually all PCB Tools and manufacturers.

ODB++: The Intelligent PCB File Format

ODB++, which stands for Open Database++, is an intelligent PCB file format that was developed by Valor Computerized Systems (now part of Mentor Graphics/Siemens) as an improvement over Gerber.

Key features of ODB++ include:

-

Single File: All layers and manufacturing data are contained in a single compressed tarball (.tgz) file, making it easier to manage than Gerber.

-

Intelligent Data: ODB++ includes netlist, component, and stackup information, enabling more advanced CAM and analysis capabilities.

-

Hierarchical Structure: The database uses a hierarchical structure with folders for different layers and features, making it easy to navigate and process.

-

Human Readable: In addition to binary data, ODB++ includes human-readable job files that describe the structure and contents of the database.

An ODB++ .tgz file typically contains the following folders:

| Folder | Contents |

|---|---|

| steps | Stackup data |

| layers | Conductor, mask, and legend layers |

| components | Component footprint data |

| features | Vias, fiducials, and other features |

| misc | Netlist, drill data, drawings |

The ASCII job file (matrix/matrix) provides a top-level description of the database structure and contents:

\#Format=2.2

\#Units=imperial

\#ZeroSuppressionMode=Leading

\#ZeroSuppressionLimit=0.0001

\#PanelSize=0.0000 0.0000

!DETAIL_UNITS_DEFINITION

U1=inches

!PADS

917500,1025000,-1102,0,11,0

920000,1025000,-1102,0,3,270

920000,1065000,-1105,0,2,90

!PACKAGES

$TEXTVALUE '3216_1'

RefDes=C1

OrgX=915000 OrgY=1025000 OrgRot=0

BBox -2500 -20000 2500 20000

More and more PCB manufacturers are supporting ODB++ as an intelligent alternative to Gerber. The main drawback is that not all PCB design tools can export to this format natively.

IPC-2581: The Future of PCB Data Transfer?

IPC-2581 is an open, vendor-neutral format for transferring PCB design data between different tools and stakeholders. It was developed by the IPC consortium as a replacement for proprietary formats and to enable bi-directional data exchange.

Key features of IPC-2581 include:

-

XML-Based: IPC-2581 uses an XML schema to represent all the design data in a human-readable format. This makes it easy to parse and process the data using standard XML tools.

-

Intelligent Data: Like ODB++, IPC-2581 includes netlist, BOM, stackup, and other intelligent data to enable advanced analysis and collaboration.

-

Bi-Directional: IPC-2581 supports bi-directional data exchange between PCB design, manufacturing, and assembly tools. This enables a true “digital thread” for PCB data.

-

Versioning: The format includes provisions for tracking changes and revisions throughout the design lifecycle.

An IPC-2581 file typically contains the following top-level XML elements:

<?xml version="1.0" encoding="UTF-8"?>

<IPC-2581

xmlns:xsi="http://www.w3.org/2001/XMLSchema-instance"

xsi:noNamespaceSchemaLocation="IPC-2581B.xsd">

<Header/>

<Products>

<Product>

<Stackup/>

<Outlines/>

<TopSide/>

<BottomSide/>

<Drills/>

<Components/>

<Materials/>

<Nets/>

<Files/>

</Product>

</Products>

<BillOfMaterials/>

<Specifications/>

<LogisticsSolutions/>

</IPC-2581>

Within each element are further details describing that aspect of the design. For example, here’s what the

<Components>

<Component refDes="C1" compInstance="1">

<Xform rotation="0" x="105.66" y="78.74"/>

<CompBody>

<Outline>

<Polyline>

<Vertex x="-1.27" y="-1.27"/>

<Vertex x="1.27" y="-1.27"/>

<Vertex x="1.27" y="1.27"/>

<Vertex x="-1.27" y="1.27"/>

<Vertex x="-1.27" y="-1.27"/>

</Polyline>

</Outline>

<Terminal refDes="1" termInstance="1" x="-1.27" y="0"/>

<Terminal refDes="2" termInstance="2" x="1.27" y="0"/>

</CompBody>

</Component>

</Components>

The adoption of IPC-2581 is still in the early stages, but it shows a lot of promise as a next-generation format for PCB data exchange. As more EDA and CAM tools add support for it, IPC-2581 could become the standard for intelligent, bi-directional PCB data transfer.

Best Practices for Working with PCB Files

To avoid common pitfalls and ensure a smooth handoff to manufacturing, follow these best practices when working with PCB files:

-

Use Standard Formats: Whenever possible, use industry standard PCB file formats like Gerber, ODB++, or IPC-2581 rather than proprietary tool-specific formats. This ensures broad compatibility and reduces the risk of translation errors.

-

Include All Necessary Files: Make sure your PCB file package includes all the necessary layers and data files for fabrication and assembly. Use a checklist to verify completeness before releasing to manufacturing.

-

Follow Naming Conventions: Use clear and consistent file naming conventions to avoid confusion. For example, use standard Gerber file extensions (.GTL, .GBL, etc.) and include the revision number in the file name.

-

Verify Design Rules: Before generating PCB files, use your CAD tool’s DRC (Design Rule Check) to verify that the design meets all manufacturing constraints such as minimum trace width, clearance, drill size, etc.

-

Generate 3D Model: In addition to the 2D fabrication files, generate a 3D STEP model of the PCB to help with mechanical integration and visualization. Many CAD tools can export 3D models directly.

-

Review and Test: Always review your PCB files in a CAM tool or viewer before releasing to ensure accuracy and completeness. If possible, have your manufacturer run a pre-production check or prototype run to validate the files.

-

Communicate with Manufacturer: Work closely with your PCB fabricator and assembler to understand their file requirements and preferences. They may have specific guidelines or templates to follow.

-

Archive and Version Control: Implement a robust system for archiving and version controlling your PCB files. This is critical for tracking changes, supporting product revisions, and enabling design reuse.

By following these best practices and selecting the appropriate PCB file formats for your needs, you can streamline the design-to-manufacturing process and ensure a high-quality end product.

PCB File FAQs

Q: What software do I need to view PCB files?

A: To view Gerber PCB files, you can use a free Gerber viewer such as Gerbv, ViewMate, or CAMtastic. For ODB++ and IPC-2581 files, you’ll need a compatible CAM tool or viewer, such as Valor NPI or IPC-2581 Viewer.

Q: Can I send my PCB design files directly from my CAD tool to a manufacturer?

A: It depends on the CAD tool and manufacturer. Some PCB design tools have built-in functions to export manufacturing files in standard formats like Gerber or ODB++. However, it’s always best to check with your specific manufacturer for their file requirements and preferences.

Q: What’s the difference between Gerber X1 and X2 formats?

A: Gerber X1 (RS-274X) is the current standard Gerber format, while Gerber X2 is a proposed update that includes additional data such as layer stackup, pad functions, and netlist information. Gerber X2 is not yet widely adopted, so most manufacturers still prefer X1.

Q: How do I ensure my PCB files are complete and error-free?

A: Most PCB design tools have built-in Design Rule Checks (DRC) and output generators that help ensure the accuracy and completeness of your manufacturing files. It’s also a good idea to review the files in a CAM tool or send them to your manufacturer for a pre-production check before finalizing the design.

Q: Can I use 3D STEP files for PCB manufacturing?

A: 3D STEP files are primarily used for mechanical integration and visualization of the PCB, not for manufacturing. To fabricate and assemble the PCB, manufacturers need the 2D Gerber, ODB++, or IPC-2581 files that contain the detailed layer and component information.

Conclusion

PCB files are the critical link between design and manufacturing, containing all the information needed to fabricate and assemble a printed circuit board. Choosing the right PCB file format and ensuring the accuracy and completeness of the data is essential for a successful outcome.

Gerber is currently the most widely used PCB file format, but more intelligent formats like ODB++ and IPC-2581 are gaining ground. By understanding the structure and capabilities of these different formats, you can select the best one for your needs and work effectively with your manufacturing partners.

Following best practices for PCB file generation, validation, and management can help you avoid costly mistakes and delays. Always communicate closely with your manufacturer and leverage their expertise to ensure a smooth handoff from design to production.

As PCB technology continues to evolve, so will the file formats and tools used to design and manufacture them. Staying up to date with these developments and adopting new standards as they emerge will be key to staying competitive in the fast-moving world of electronics.

Leave a Reply