Aspect 1: Technical Expertise and Experience

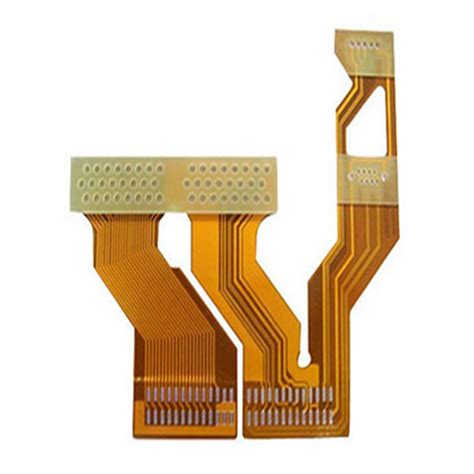

One of the most critical factors in choosing a Flex PCB Supplier is their technical expertise and experience in the field. Look for a supplier with a proven track record of successfully delivering flex PCB Prototypes across various industries and applications. They should have a deep understanding of the latest technologies, materials, and manufacturing processes involved in creating high-quality flex PCBs.

Key Points to Consider:

- Years of experience in the flex PCB industry

- Range of industries and applications served

- Familiarity with the latest technologies and materials

- Ability to provide expert guidance and support throughout the project

Aspect 2: Manufacturing Capabilities and Facilities

A reliable flex PCB supplier should have state-of-the-art manufacturing facilities equipped with advanced technology and equipment. This ensures that they can handle complex designs and deliver high-quality prototypes consistently. It’s essential to assess their manufacturing capabilities, including their ability to handle different layer counts, material types, and special requirements such as controlled impedance or fine-pitch traces.

Manufacturing Capabilities Checklist:

- Multi-layer flex PCB fabrication (e.g., 1-12 layers)

- Variety of materials (e.g., polyimide, PTFE, PET)

- Minimum feature sizes (e.g., trace width, spacing, hole size)

- Special requirements (e.g., controlled impedance, fine-pitch traces)

- In-house testing and quality control processes

Aspect 3: Quality Control and Certifications

Quality is paramount when it comes to flex PCB prototypes. A reputable supplier should have stringent quality control processes in place to ensure that every prototype meets the highest standards of reliability and performance. Look for suppliers with relevant certifications such as ISO 9001, UL, and IPC, which demonstrate their commitment to quality and adherence to industry standards.

Quality Control Measures to Look For:

- Automated optical inspection (AOI)

- Electrical testing (e.g., flying probe, ICT)

- Microsectioning and cross-sectioning analysis

- Thermal cycling and environmental testing

- Relevant certifications (e.g., ISO 9001, UL, IPC)

Aspect 4: Turnaround Time and Delivery

In today’s fast-paced market, time is of the essence. Your flex PCB supplier should be able to offer quick turnaround times without compromising on quality. Inquire about their standard lead times for prototype production and their ability to accommodate rush orders if needed. Additionally, consider their location and shipping capabilities to ensure timely delivery of your prototypes.

Factors Affecting Turnaround Time:

- Standard lead times for prototype production

- Express or rush order options

- Supplier’s location and proximity to your facility

- Shipping methods and delivery reliability

Aspect 5: Customer Support and Communication

Effective communication and responsive customer support are essential for a smooth and successful flex PCB prototype project. Your supplier should be easily accessible and willing to address your concerns and questions promptly. They should also provide regular updates on the progress of your project and be proactive in resolving any issues that may arise.

Signs of Good Customer Support:

- Dedicated project manager or point of contact

- Quick response times to inquiries and concerns

- Regular project updates and progress reports

- Proactive problem-solving and issue resolution

- Clear and transparent communication channels

Aspect 6: Design Support and Feedback

A valuable flex PCB supplier should offer more than just manufacturing services. They should also provide design support and feedback to help optimize your prototype design for manufacturability and performance. Look for suppliers with experienced engineering teams who can review your design files, provide suggestions for improvement, and assist with material selection and stackup design.

Design Support Services to Expect:

- Design rule checks (DRC) and manufacturability review

- Material selection and stackup design assistance

- Signal integrity analysis and simulation

- Prototype testing and validation

- Design for manufacturing (DFM) recommendations

Aspect 7: Cost and Value for Money

While cost is an important consideration, it should not be the sole deciding factor when choosing a flex PCB supplier. Focus on finding a supplier that offers the best value for money – a balance between competitive pricing, high quality, and reliable service. Be cautious of suppliers with prices that seem too good to be true, as they may cut corners on quality or use inferior materials.

Factors Affecting Cost and Value:

- Prototype complexity and layer count

- Material selection and special requirements

- Order quantity and production volume

- Turnaround time and expedited services

- Additional services (e.g., design support, testing)

Aspect 8: Scalability and Future Support

When selecting a flex PCB supplier for your prototype, it’s essential to consider their ability to support your project as it grows and transitions into production. A supplier that can seamlessly scale up their manufacturing capabilities to meet your increasing demand will save you time and effort in the long run. Additionally, look for suppliers that offer value-added services such as assembly, testing, and box build to streamline your supply chain.

Scalability Factors to Consider:

- Supplier’s production capacity and flexibility

- Ability to handle high-volume orders

- Experience in transitioning from prototype to production

- Value-added services (e.g., assembly, testing, box build)

- Long-term partnership and support

Frequently Asked Questions (FAQ)

-

Q: How long does it typically take to produce a flex PCB prototype?

A: The turnaround time for a flex PCB prototype can vary depending on the complexity of the design and the supplier’s workload. Generally, standard lead times range from 5 to 15 working days, while express services may offer shorter lead times of 1 to 5 days. -

Q: What materials are commonly used in flex PCB prototypes?

A: The most common materials used in flex PCB prototypes are polyimide (PI) and polyethylene terephthalate (PET). Polyimide is known for its high temperature resistance and durability, while PET is a more cost-effective option for less demanding applications. Other materials like PTFE may be used for high-frequency or low-loss applications. -

Q: How can I ensure that my flex PCB prototype design is manufacturable?

A: To ensure that your flex PCB prototype design is manufacturable, work closely with your supplier’s engineering team. They can provide design rule checks (DRC), manufacturability reviews, and design for manufacturing (DFM) recommendations. Following industry standards like IPC and adhering to your supplier’s design guidelines will also help minimize issues during production. -

Q: What should I look for in a flex PCB supplier’s quality control process?

A: A reliable flex PCB supplier should have a robust quality control process that includes automated optical inspection (AOI), electrical testing, microsectioning, and cross-sectioning analysis. They should also conduct thermal cycling and environmental testing to ensure the prototype’s reliability. Look for suppliers with relevant certifications like ISO 9001, UL, and IPC, which demonstrate their commitment to quality. -

Q: How can I balance cost and quality when selecting a flex PCB prototype supplier?

A: To balance cost and quality, focus on finding a supplier that offers the best value for money. This means considering factors beyond just the price, such as the supplier’s technical expertise, manufacturing capabilities, quality control processes, and customer support. Don’t automatically opt for the cheapest option, as it may come at the expense of quality and reliability. Instead, look for a supplier that can deliver high-quality prototypes at a competitive price while providing excellent service and support.

Conclusion

Selecting the right flex PCB prototype supplier is a critical decision that can significantly impact the success of your project. By carefully considering the eight aspects discussed in this article – technical expertise, manufacturing capabilities, quality control, turnaround time, customer support, design support, cost, and scalability – you can make an informed choice and find a supplier that meets your specific needs and requirements.

Remember, a good flex PCB supplier should be more than just a manufacturer; they should be a partner invested in your project’s success. By fostering a strong relationship with your supplier and leveraging their expertise and support, you can bring your innovative flex PCB designs to life and stay ahead in today’s competitive market.

Leave a Reply