Introduction

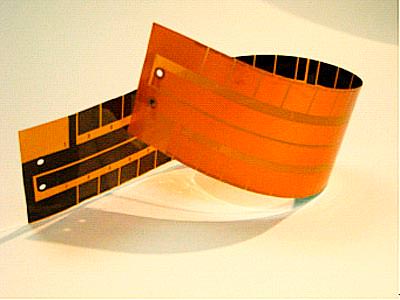

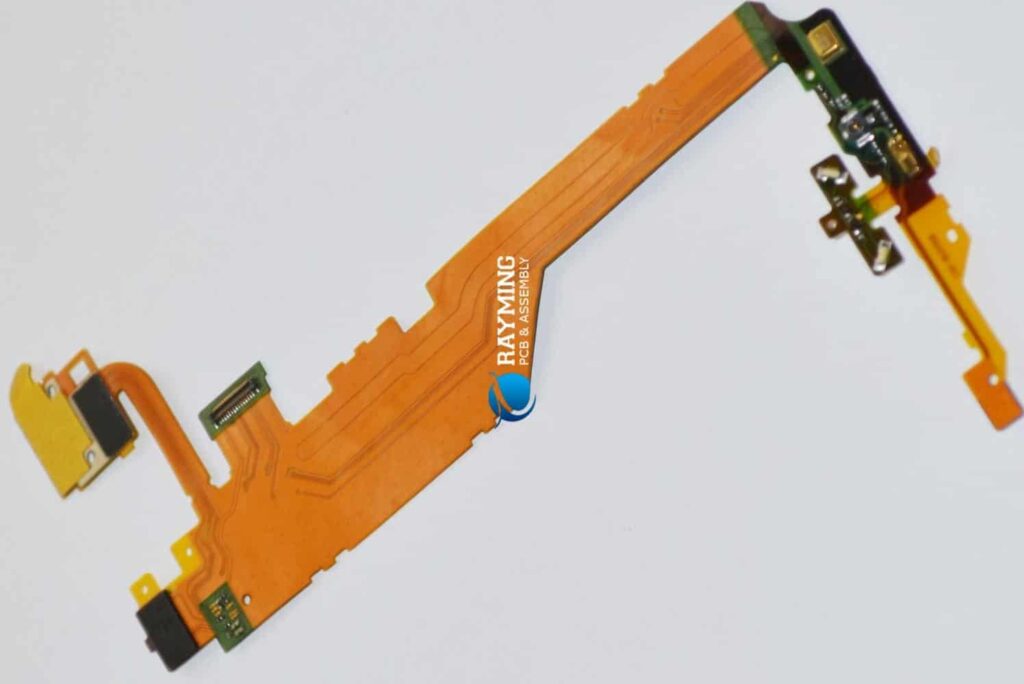

Flex PCBs (flexible printed circuit boards) are gaining popularity for their ability to bend and flex to fit into tight or moving spaces. As devices get smaller and more complex, flex PCBs provide the perfect interconnect solution. However, getting an accurate flex PCB quote online can be challenging with so many options to consider. This guide will walk you through the key steps to get the right flex PCB quote for your project.

Determine the Flex PCB Specifications

The first step is defining your flex PCB requirements so manufacturers can provide an accurate quote. Here are the key specifications to have ready:

Layer Count

How many conductive copper layers do you need? The number of layers impacts flex PCB cost and manufacturing complexity. Common options are single, double, and multilayer.

Board Dimensions

Provide the length, width, and shape of the flex PCB. Irregular shapes will cost more than rectangular designs.

Bend Radius

Specify the minimum bend radius needed. Tighter bends increase complexity and price.

Board Thickness

Thinner boards are more flexible but more expensive to produce. Common thicknesses are 0.5mm to 3mm.

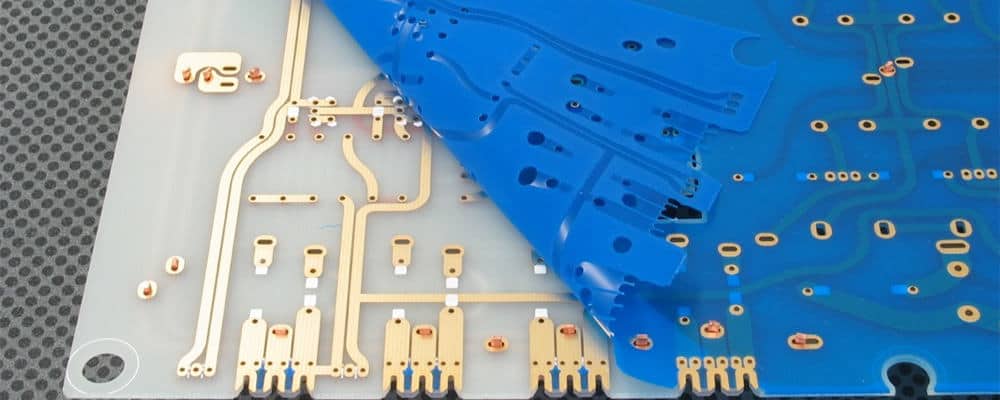

Layer Stackup

Define the materials used for each layer (e.g. polyimide, adhesive, copper thickness).

Board Finish

The coating applied to the copper traces like immersion silver, ENIG, or tin.

Stiffeners

Will rigid sections or stiffeners be required? These support segments help manage stresses.

Minimum Features

The smallest line width, spacing, hole size, etc. that must be achieved.

Estimate the Quantities Needed

Providing volume estimates helps manufacturers gauge production costs:

- Prototypes – Low volumes for initial testing and evaluation. Often 10-50 boards.

- Pre-production – Higher volumes of 100-500 to validate the design before full-scale production.

- Production – Large ongoing volumes of 500+ boards. Higher volumes mean lower per unit costs.

Upload Your Documentation

To get an accurate quote, manufacturers will need complete documentation of your flex PCB design including:

- Gerber Files – Standard files describing board layers, solder masks, silkscreen, etc.

- Mechanical Drawings – Files visually detailing board dimensions, bend radii, stiffener locations, etc.

- Assembly Drawings – Files showing part locations, placements, and orientations for populated boards.

- Bill of Materials – List of all components to be assembled onto the flex PCB.

Providing comprehensive documentation reduces errors and ensures an accurate quote.

Select Flex PCB Materials

Another factor impacting flex PCB cost is the material used for the flexible substrate and layers:

| Material | Description | Price |

|---|---|---|

| Polyimide | Most common. Withstands bending and flexing. | $$ |

| Polyester | Low cost but less heat resistant. | $ |

| PEEK | High temp resistance. Chemically inert. | $$$ |

| Polyurethane | Extreme flexibility. Abrasion resistant. | $$ |

Consider mechanical, thermal, and chemical needs when selecting base materials. Discuss material questions with manufacturers.

Evaluate Additional Options

Consider which additional flex PCB capabilities and services are required:

- Stiffener Cutouts – Openings in rigid sections to allow routing of traces.

- Carbon Ink Heaters – Embedded heating elements to warm components.

- Functional Testing – Validation of boards before shipment.

- Flying Probe – Testing of assembled boards.

- kitting – Individual packing of boards/components for easy assembly.

Add-ons like these increase costs but may be vital. Discuss with manufacturers to make the best choice.

Request Flex PCB Samples

Asking for free design samples is a great way to evaluate manufacturer capabilities and accuracy. Be sure to request:

- Samples with different bend radii

- Samples showing minimum line/space tolerances

- Samples with and without stiffeners

Hands-on samples reveal material quality, workmanship, and precision.

Get Multiple Quotes

Reach out to 3-4 manufacturers to get several quotes. Comparing prices and options helps find the best value. When reviewing quotes:

- Verify all specifications are met

- Look for inconsistencies or errors

- Confirm production time estimates

- Check certifications and quality systems

Don’t just focus on the bottom line cost. The lowest quote may not provide the best quality or service.

Choosing a Flex PCB Manufacturer

When selecting a manufacturer, look for these key capabilities:

- Experience with complex multilayer flex designs

- Precision manufacturing with tight tolerances

- Rigorous quality systems like ISO 9001

- Strong engineering support for design reviews

- Flexible order volumes from prototypes to high-volume production

Take time to evaluate vendors and contact references to find the right partner.

Frequently Asked Questions

What design software do I need for flex PCBs?

Any standard PCB design software like Altium, Cadence, or Eagle can be used. The software needs to support designing rigid-flex boards with multiple bend areas.

Can components be mounted on flex PCBs?

Yes, components can be soldered or adhered onto flex PCBs. Stiffener areas often support heavier components. Use stress relief techniques for leads or traces.

How long does flex PCB manufacturing take?

Timeframes range from 2 days for simple prototype boards to 4-6 weeks for complex multilayer production boards, depending on volumes.

Is e-test possible on flex PCBs?

Testing assembled boards with an automated flying probe or fixture is definitely possible. Rigid areas of the board allow probes to make contact.

How are flex PCBs protected from the environment?

Conformal coatings like acrylic, silicone, or urethane can be applied to shield from moisture, dust, chemicals etc. Encapsulation is another option.

Conclusion

Getting accurate flex PCB quotes requires carefully defining requirements, selecting materials, evaluating manufacturers, and asking questions. Use this guide as a checklist when sourcing your next flex PCB to get the optimal design at the best price. With an expert partner, flex PCBs can enable innovative and compact product designs.

Leave a Reply