What Are Semiconductor Chips?

Semiconductor chips, also known as integrated circuits (ICs) or microchips, are the brains behind modern electronics. These tiny components, made from semiconductor materials like silicon, contain millions or billions of transistors that process and store data, enabling the functionality of devices such as:

- Computers and laptops

- Smartphones and tablets

- Televisions and gaming consoles

- Automotive electronics

- Industrial equipment

- Medical devices

Semiconductor chips come in various types, each designed for specific applications:

| Chip Type | Description | Examples |

|---|---|---|

| Microprocessors | The central processing unit (CPU) of a device, handling general-purpose computing tasks | Intel Core, AMD Ryzen |

| Memory Chips | Store temporary (RAM) or permanent (ROM) data for quick access | DRAM, NAND Flash |

| Analog Chips | Process continuous signals like sound, light, and temperature | Amplifiers, sensors |

| Logic Chips | Perform Boolean logic operations and control the flow of data | FPGAs, ASICs |

Causes of the Global Chip Shortage

The current chip shortage is the result of a perfect storm of factors, including:

Increased Demand Due to the COVID-19 Pandemic

The COVID-19 pandemic has dramatically accelerated the digital transformation of businesses and education, leading to a surge in demand for devices like laptops, tablets, and webcams. Additionally, stay-at-home orders have driven up demand for consumer electronics, gaming consoles, and home entertainment systems.

Supply Chain Disruptions

The pandemic has also disrupted global supply chains, making it harder for chip manufacturers to obtain raw materials and components. Lockdowns and travel restrictions have led to production delays and capacity constraints at chip fabrication plants (fabs).

Trade Tensions and Geopolitical Factors

Trade tensions between the U.S. and China have exacerbated the chip shortage, as the U.S. government has imposed export restrictions on Chinese tech companies, limiting their access to advanced semiconductor technology. This has led to stockpiling and increased competition for the remaining supply.

Natural Disasters and Accidents

Several natural disasters and accidents have further strained chip production:

- A drought in Taiwan, home to the world’s largest chip manufacturer TSMC, has threatened water supply for chip production

- A fire at a Japanese chip factory owned by Renesas Electronics disrupted automotive chip supply

- Winter storms in Texas forced the shutdown of Samsung and NXP Semiconductors fabs

Underinvestment in Chip Production Capacity

The semiconductor industry is capital-intensive, with new fabs costing billions of dollars and taking years to build. Many chip companies have been reluctant to invest in new capacity due to the cyclical nature of the industry and the high costs involved.

Impact of the Chip Shortage

The chip shortage has far-reaching consequences across industries:

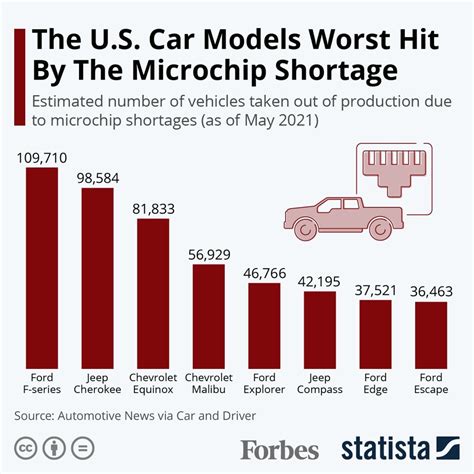

Automotive Industry

The automotive industry has been hit particularly hard by the chip shortage, as modern vehicles rely heavily on semiconductor chips for various functions, from engine management to infotainment systems. Major automakers like Ford, GM, and Toyota have had to cut production, leading to lower sales and revenue.

| Automaker | Production Cuts (2021) | Estimated Revenue Loss |

|---|---|---|

| Ford | 1.1 million vehicles | $2.5 billion |

| GM | 800,000 vehicles | $2.0 billion |

| Toyota | 500,000 vehicles | $1.5 billion |

Consumer Electronics

The shortage has led to scarcity and higher prices for popular consumer electronics:

- Gaming consoles like the PlayStation 5 and Xbox Series X/S have been in short supply since their launch

- Smartphone makers have had to delay product launches or cut production, leading to longer wait times for consumers

- Laptop and tablet prices have increased due to the shortage of components like display panels and memory chips

Industrial and Medical Equipment

The chip shortage has also affected the production of industrial and medical equipment, such as:

- Factory automation systems

- Robotics and drones

- Medical imaging devices (e.g., CT scanners, MRI machines)

- Ventilators and other critical care equipment

This has led to delays in the deployment of new technologies and potential impacts on patient care.

Potential Solutions to the Chip Shortage

Resolving the global chip shortage will require a multi-faceted approach:

Increasing Chip Production Capacity

Governments and chip companies are investing in new fabs and expanding existing facilities to boost production capacity. For example:

- TSMC is investing $100 billion over three years to expand its manufacturing capacity

- Intel is investing $20 billion in two new fabs in Arizona, USA

- Samsung is considering a $17 billion fab in Texas, USA

However, building new fabs is a long-term solution, as it can take 2-3 years for a new facility to become operational.

Improving Supply Chain Resilience

Companies are working to diversify their supply chains and reduce their reliance on single sources for critical components. This may involve:

- Developing alternative sources for raw materials and components

- Strengthening relationships with suppliers and increasing transparency

- Investing in inventory management and demand forecasting systems

Advancing Chip Design and Packaging Technologies

Innovations in chip design and packaging can help mitigate the impact of the shortage:

- Chiplet-based design allows for more flexible and modular chip construction

- Advanced packaging techniques like 3D stacking can increase chip density and performance

- Artificial intelligence and machine learning can optimize chip design and production processes

Government Policies and Incentives

Governments around the world are implementing policies and incentives to support the semiconductor industry and address the chip shortage:

- The U.S. CHIPS for America Act provides $52 billion in funding for domestic chip production and research

- The European Union is planning to invest €145 billion to boost its share of global chip production from 10% to 20% by 2030

- China is offering tax breaks and subsidies to encourage domestic chip production

FAQ

Q: When is the chip shortage expected to end?

A: Experts predict that the chip shortage may last into 2023 or even 2024, depending on the success of efforts to increase production capacity and stabilize supply chains.

Q: Which industries are most affected by the chip shortage?

A: The automotive and consumer electronics industries have been hit hardest by the shortage, with production cuts and product delays. However, the impact is being felt across nearly all sectors that rely on semiconductor chips.

Q: How can consumers cope with the chip shortage?

A: Consumers may need to be patient and flexible when seeking to purchase electronics affected by the shortage. Consider alternative products, be prepared for longer wait times, and keep an eye out for restocks at retailers.

Q: Will the chip shortage lead to long-term changes in the semiconductor industry?

A: Yes, the shortage has highlighted the need for greater investment in chip production capacity, supply chain resilience, and geographic diversification. It may also accelerate the adoption of new technologies and business models in the industry.

Q: What role can governments play in addressing the chip shortage?

A: Governments can provide funding, incentives, and policy support to encourage domestic chip production, research and development, and workforce training. They can also work to facilitate international cooperation and trade in the semiconductor industry.

The global chip shortage is a complex and evolving challenge that requires a coordinated response from industry, government, and academia. By investing in production capacity, supply chain resilience, and technological innovation, we can work towards a more stable and sustainable future for the semiconductor industry and the countless sectors that depend on it.

Leave a Reply