Understanding the Role of Decoupling Capacitors

Before we dive into the specifics of determining the Decoupling Capacitor Value, let’s first understand the fundamental role of these components in electronic circuits.

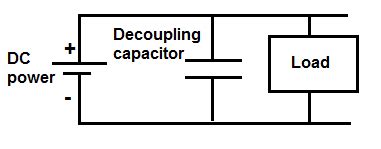

Power Supply Noise Reduction

One of the primary functions of decoupling capacitors is to reduce power supply noise. When ICs switch rapidly, they draw sudden bursts of current from the power supply, causing voltage fluctuations known as noise. This noise can propagate throughout the circuit, leading to signal integrity issues and potentially causing malfunctions. By placing decoupling capacitors close to the power pins of ICs, the capacitors act as local energy reservoirs, providing a low-impedance path for high-frequency noise to be shunted to ground. This helps maintain a stable power supply voltage and minimizes the impact of noise on the circuit.

High-Frequency Filtering

In addition to reducing power supply noise, decoupling capacitors also serve as high-frequency filters. They effectively bypass high-frequency noise components, preventing them from entering sensitive parts of the circuit. By creating a low-impedance path to ground for high-frequency signals, decoupling capacitors help maintain signal integrity and prevent unwanted interference.

Transient Response Improvement

Decoupling capacitors also play a crucial role in improving the transient response of the power supply. When an IC experiences a sudden increase in current demand, the power supply may not be able to respond instantaneously, leading to a temporary voltage drop. Decoupling capacitors act as local energy reservoirs, supplying the required current during these transient events and helping to maintain a stable voltage level. This is particularly important for high-speed digital circuits where rapid switching occurs.

Factors Influencing Decoupling Capacitor Selection

Choosing the right decoupling capacitor value involves considering several key factors that impact the circuit’s performance. Let’s explore these factors in detail.

Frequency of Operation

The frequency of operation is a critical factor in determining the decoupling capacitor value. Different capacitor values are effective at different frequency ranges. Generally, smaller capacitor values are more effective at higher frequencies, while larger values are better suited for lower frequencies. It’s important to consider the frequency spectrum of the noise present in your circuit and select capacitor values that effectively target those frequencies.

Frequency Response of Capacitors

Capacitors exhibit a frequency-dependent impedance characteristic. At lower frequencies, capacitors have a higher impedance, while at higher frequencies, their impedance decreases. This behavior is described by the capacitive reactance formula:

Xc = 1 / (2πfC)

Where:

– Xc is the capacitive reactance in ohms (Ω)

– f is the frequency in hertz (Hz)

– C is the capacitance in farads (F)

As the frequency increases, the capacitive reactance decreases, allowing the capacitor to provide a lower impedance path for high-frequency noise.

Selecting Capacitor Values Based on Frequency

When selecting decoupling capacitor values based on frequency, it’s common to use a combination of different capacitor values to cover a wide frequency range. A typical approach is to use a larger bulk capacitor (e.g., 10 μF to 100 μF) to handle low-frequency noise and provide bulk energy storage, accompanied by smaller ceramic capacitors (e.g., 0.1 μF to 1 μF) to target high-frequency noise.

Here’s an example of how you might choose capacitor values based on frequency:

| Frequency Range | Capacitor Value |

|---|---|

| 0 – 100 kHz | 10 μF – 100 μF |

| 100 kHz – 1 MHz | 1 μF – 10 μF |

| 1 MHz – 100 MHz | 0.01 μF – 1 μF |

| 100 MHz+ | 1 nF – 100 nF |

It’s important to note that these values are general guidelines, and the specific values may vary depending on the requirements of your circuit.

Power Supply Voltage and Current

The power supply voltage and current requirements of your circuit also influence the selection of decoupling capacitor values. Higher voltage and current demands generally require larger capacitance values to ensure adequate energy storage and minimize voltage fluctuations.

Voltage Rating

When choosing decoupling capacitors, it’s crucial to consider the voltage rating of the capacitors. The voltage rating should be higher than the maximum expected voltage in the circuit, including any transient spikes. A good rule of thumb is to select capacitors with a voltage rating at least 50% higher than the nominal power supply voltage. For example, if your circuit operates at 5 V, choose capacitors with a voltage rating of at least 7.5 V to provide a safety margin.

Current Rating

The current rating of the decoupling capacitors is another important consideration. The capacitors should be able to handle the expected ripple current without overheating or degrading over time. The ripple current is the AC component of the current flowing through the capacitor, and it’s influenced by factors such as the switching frequency and the load current. Manufacturers typically provide ripple current ratings for their capacitors, and it’s essential to select capacitors that can handle the expected ripple current in your circuit.

PCB Layout and Placement

The placement and layout of decoupling capacitors on the printed circuit board (PCB) play a significant role in their effectiveness. Proper placement helps minimize the impedance between the capacitors and the ICs they are decoupling, ensuring optimal performance.

Placement Guidelines

When placing decoupling capacitors on the PCB, follow these guidelines:

-

Place the capacitors as close as possible to the power pins of the ICs they are decoupling. This minimizes the inductance and impedance between the capacitors and the ICs, allowing for effective noise suppression.

-

Use short and wide traces to connect the capacitors to the power and ground planes. This reduces the trace inductance and provides a low-impedance path for high-frequency noise.

-

If using multiple capacitor values, place the smaller capacitors closer to the ICs and the larger capacitors farther away. The smaller capacitors target high-frequency noise, while the larger capacitors provide bulk energy storage and handle low-frequency noise.

-

Avoid placing decoupling capacitors too close to high-speed signal traces to minimize the risk of crosstalk and interference.

Power and Ground Planes

In multi-layer PCBs, it’s recommended to use dedicated power and ground planes to distribute power effectively and minimize impedance. The power and ground planes should be placed on adjacent layers, separated by a thin dielectric material. This configuration creates a low-impedance, high-frequency bypass path for noise currents, enhancing the effectiveness of decoupling capacitors.

Capacitor Type and Material

The type and material of the decoupling capacitors also influence their performance and suitability for specific applications.

Ceramic Capacitors

Ceramic capacitors, particularly multilayer ceramic capacitors (MLCCs), are widely used for decoupling purposes due to their excellent high-frequency performance, low equivalent series resistance (ESR), and small package size. They are available in a wide range of capacitance values and voltage ratings, making them suitable for most decoupling applications.

However, ceramic capacitors can exhibit a phenomenon called “DC bias effect,” where the capacitance value decreases as the applied DC voltage increases. This effect should be considered when selecting ceramic capacitors, especially in high-voltage applications.

Tantalum and Electrolytic Capacitors

Tantalum and electrolytic capacitors offer higher capacitance values in compact packages compared to ceramic capacitors. They are commonly used for bulk energy storage and low-frequency decoupling. However, they have higher ESR and lower high-frequency performance compared to ceramic capacitors.

Tantalum capacitors are known for their stability and reliability, making them suitable for applications that require long-term performance. Electrolytic capacitors, on the other hand, offer the highest capacitance values but have limited high-frequency performance and higher ESR.

Determining the Optimal Decoupling Capacitor Value

Now that we’ve explored the factors influencing decoupling capacitor selection, let’s discuss the process of determining the optimal capacitor value for your circuit.

Calculating the Required Capacitance

To determine the required decoupling capacitance, you need to consider the following parameters:

- Power supply voltage (V)

- Maximum expected load current (I)

- Allowable voltage ripple (ΔV)

- Switching frequency (f)

The required decoupling capacitance can be calculated using the following formula:

C = I / (2πfΔV)

Where:

– C is the required capacitance in farads (F)

– I is the maximum expected load current in amperes (A)

– f is the switching frequency in hertz (Hz)

– ΔV is the allowable voltage ripple in volts (V)

For example, let’s say you have a circuit with a 5 V power supply, a maximum load current of 1 A, an allowable voltage ripple of 100 mV (0.1 V), and a switching frequency of 100 MHz. Plugging these values into the formula, we get:

C = 1 A / (2π × 100 MHz × 0.1 V) ≈ 159 nF

In this case, you would choose a decoupling capacitor value close to 159 nF, such as 150 nF or 180 nF, depending on the available standard values.

Selecting the Appropriate Capacitor Package

Once you have determined the required capacitance value, the next step is to select the appropriate capacitor package. The package size and type depend on factors such as the available PCB space, the required voltage and current ratings, and the desired high-frequency performance.

Common capacitor packages for decoupling include:

- 0201, 0402, 0603, 0805: These are small surface-mount packages suitable for high-density PCB layouts and high-frequency decoupling.

- 1206, 1210: These are larger surface-mount packages that offer higher capacitance values and current handling capabilities.

- Radial and axial through-hole packages: These are through-hole packages commonly used for larger capacitance values and high-voltage applications.

When selecting the capacitor package, consider the space constraints on your PCB and choose a package that fits within the available area while meeting the required electrical specifications.

Parallel Combination of Capacitors

In some cases, a single capacitor value may not provide optimal decoupling performance across the entire frequency range of interest. In such situations, you can use a parallel combination of capacitors with different values to achieve a wider frequency coverage.

For example, you can use a larger bulk capacitor (e.g., 10 μF) in parallel with a smaller ceramic capacitor (e.g., 0.1 μF) to combine the benefits of low-frequency and high-frequency decoupling. The larger capacitor provides bulk energy storage and handles low-frequency noise, while the smaller capacitor targets high-frequency noise and improves transient response.

When using parallel combinations, ensure that the capacitors are placed close together on the PCB to minimize the impedance between them.

Simulation and Validation

After selecting the decoupling capacitor values and layout, it’s important to simulate and validate the circuit’s performance to ensure optimal decoupling.

Simulation Tools

There are several simulation tools available that can help you analyze the decoupling network and assess its effectiveness. Some popular tools include:

- SPICE simulators (e.g., LTspice, PSpice)

- Electromagnetic field solvers (e.g., Ansys HFSS, CST Studio Suite)

- Power integrity simulation tools (e.g., Cadence Sigrity, Mentor Graphics HyperLynx)

These tools allow you to model the decoupling network, including the capacitors, PCB layout, and IC power delivery network, and simulate the circuit’s behavior under various operating conditions. By performing AC and transient analysis, you can evaluate the impedance profile, voltage ripple, and transient response of the decoupling network.

Measurement and Validation

After simulating the decoupling network, it’s crucial to validate its performance through measurements on the actual hardware. Some common measurement techniques for decoupling validation include:

-

Impedance measurement: Use a vector network analyzer (VNA) or impedance analyzer to measure the impedance profile of the decoupling network across the frequency range of interest. Compare the measured impedance with the simulated results to verify the effectiveness of the decoupling capacitors.

-

Ripple voltage measurement: Use an oscilloscope to measure the voltage ripple on the power supply rails under different load conditions. Ensure that the measured ripple voltage is within the acceptable limits defined in your design specifications.

-

Transient response measurement: Measure the transient response of the power supply voltage during sudden load changes or switching events. Verify that the voltage remains stable and within the specified limits during these transient events.

By comparing the measured results with the simulated predictions, you can validate the effectiveness of your decoupling network and make any necessary adjustments to optimize its performance.

Frequently Asked Questions (FAQ)

-

What is the purpose of decoupling capacitors in electronic circuits?

Decoupling capacitors serve multiple purposes in electronic circuits, including reducing power supply noise, providing high-frequency filtering, and improving transient response. They help maintain signal integrity and stability by providing a low-impedance path for high-frequency noise to be shunted to ground and acting as local energy reservoirs to supply current during sudden load changes. -

How do I choose the right decoupling capacitor value for my circuit?

Choosing the right decoupling capacitor value involves considering several factors, such as the frequency of operation, power supply voltage and current requirements, PCB layout and placement, and capacitor type and material. The required capacitance can be calculated using the formula C = I / (2πfΔV), where I is the maximum expected load current, f is the switching frequency, and ΔV is the allowable voltage ripple. It’s common to use a combination of different capacitor values to cover a wide frequency range. -

What are the common capacitor types used for decoupling?

The most common capacitor types used for decoupling are ceramic capacitors, particularly multilayer ceramic capacitors (MLCCs), due to their excellent high-frequency performance, low ESR, and small package size. Tantalum and electrolytic capacitors are also used for bulk energy storage and low-frequency decoupling, offering higher capacitance values but with higher ESR and lower high-frequency performance compared to ceramic capacitors. -

How important is the placement of decoupling capacitors on the PCB?

The placement of decoupling capacitors on the PCB is crucial for their effectiveness. Capacitors should be placed as close as possible to the power pins of the ICs they are decoupling to minimize the inductance and impedance between them. Short and wide traces should be used to connect the capacitors to the power and ground planes. Proper placement helps ensure optimal noise suppression and transient response. -

How can I validate the effectiveness of my decoupling network?

Validating the effectiveness of a decoupling network involves both simulation and measurement techniques. Simulation tools like SPICE simulators, electromagnetic field solvers, and power integrity simulation tools can be used to model and analyze the decoupling network’s performance. Measurements such as impedance measurement, ripple voltage measurement, and transient response measurement can be performed on the actual hardware to verify the decoupling network’s effectiveness and compare the results with the simulated predictions.

Conclusion

Selecting the appropriate decoupling capacitor value is essential for ensuring signal integrity, reducing noise, and maintaining a stable power supply in electronic circuits. By understanding the factors that influence decoupling capacitor selection, such as frequency of operation, power supply requirements, PCB layout, and capacitor type, you can make informed decisions when designing your decoupling network.

Remember to consider the frequency response of capacitors, choose appropriate values based on the frequency range of interest, and use a combination of different capacitor values to cover a wide frequency spectrum. Pay attention to the voltage and current ratings of the capacitors, and select packages that fit within the available PCB space while meeting the required electrical specifications.

Proper placement and layout of decoupling capacitors on the PCB are crucial for their effectiveness. Place the capacitors close to the power pins of the ICs they are decoupling, use short and wide traces, and consider the use of power and ground planes for optimal performance.

Finally, simulate and validate your decoupling network using appropriate tools and measurement techniques to ensure its effectiveness and make any necessary adjustments.

By following these guidelines and understanding the principles behind decoupling capacitor selection, you can design robust and reliable electronic circuits that maintain signal integrity and provide stable power delivery.

Leave a Reply